Now - 13:33:18

Acetate. The production of acetate fiber

At all times the textile industry was one of the most important industries in our country, as it gave the state a huge amount so it needs tissue, which is constantly required not only for clothing, but even used in the production of arms.

But because almost from the first days of the Soviet Union before chemists were tasked with the production of artificial fabrics, so natural materials are sorely lacking. The result was a acetate.

But because almost from the first days of the Soviet Union before chemists were tasked with the production of artificial fabrics, so natural materials are sorely lacking. The result was a acetate.

What is it?

In Fairness, it should be noted that the so-called not some one particular kind of fabric and several types of artificial fibers. In all cases, make them out of cellulose acetate. The most common fibers from triacetylcellulose, as well as conventional acetate fiber produced from recycled cellulose acetate.

Important qualities of man-made fibers

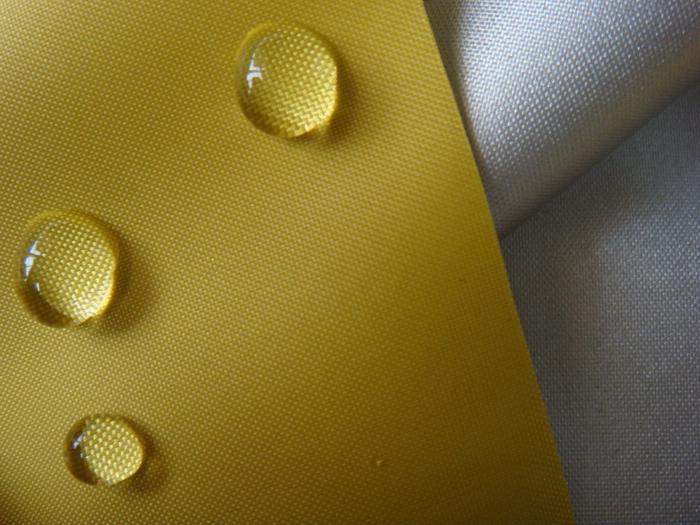

The water Absorption of such fabrics does not exceed 3.5%. Fiber almost does not absorb moisture, does not swell and does not allow precipitation even after multiple cycle of soaking/drying. In comparison with natural fabrics and artificial much less exposed to microorganisms, heat and light. In addition, they are completely indifferent mol. Tissue these is capable without losing its qualities to withstand heat up to 100 degrees Celsius.

Clothes made of acetate fibers, very pleasant to look at, great to wash and dry out quickly. In addition, when washing you need to add much less detergent, as dirt is easily washed away from the fibers of a given type.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Note that weak acids and alkalis no effect on acetate so damaging, as in the case of natural fabrics, but in the end it is saponified and loses much of its beneficial qualities. The same concentrated inorganic acids from destroying it.

Microscopic structure of fiber

If you look at this tissue under the microscope, you can see hundreds of longitudinal grooves on the fiber surface. Because of this, individual filaments do not adhere with each other, and the fabric overall is quite elastic and badly crushed. Glitter they have in common in appearance with natural silk, and the thickness of the individual fibers is quite similar to the thread which is given to the larvae of silkworms. If the manufacturer faces the challenge of obtaining a fabric in which the strands are securely linked together on the surface of the fibers are made of H-shaped transverse incisions.

In addition to high tensile strength, this fabric is characterized by a very beautiful sparkling Shine, but because it is often used in ornamental purposes.

Disadvantages of acetate fabrics

Unfortunately, all is not well: these kinds of artificial materials are very poorly resist abrasion very easily gain static electricity, poorly painted standard colors that are commonly used in the textile industry. Their stroke should, without raising the temperature of the iron above 115°, otherwise possible thermal deformation.

Other negative qualities

Given the very high ability of acetate fibers to accumulate static charge, it is quite difficult to produce a fabric. If when Ironing a little bit to overdo it with the temperature of the iron, on the surface there are deep defects that are impossible to resolve. Acetate burns with a bright yellow color. Quite easily quenched, and then smolders for a long time, releasing into the surrounding air a large amount of dense smoke and odor.

Production

As you might understand, acetate is produced from cellulose. Of course, it is preferable to use cotton, but its lack or absence, it is possible to use high-quality wood. After production and purification it is treated with acetic anhydride. As a catalyst for the reaction using sulfuric acid as to dissolve the cellulose acetate is added to acetic acid.

In the presence of a small amount of water fibers start to amylase, resulting in deacetylase. To the obtained substance is added to a mixture of acetone and water (95:1). All the spinning mixture is ready. It is filtered, cleaning of the overabundance of coarse mechanical impurities, and then sent to the spinning machine. Getting the acetate fiber is in air (dry method).

This method is good also what not require the use of any additional chemicals. Thick and viscous spinning mass is simply pressed through a die with plurality of holes, and then enters the vapour chamber at a temperature of about 87 degrees Celsius. Since the production of acetate fiber requires a huge amount of water and cellulose, many plants are located near lake Baikal.

Some information about the color

The High temperature is necessary so that the acetone completely evaporated from the mixture. Thereafter, the resulting filaments are cooled, cover the surface with oil to prevent the formation of static charge, and then wound on a bobbin. Per minute to 600 is formedmeters of thread. In the future, it requires almost no processing, with the exception only of lay in the production of thicker fibers.

What about the color? In most cases, dye is injected at the production stage, so that a bobbin of wound thread in the desired color. We have already said that acetate very badly stained by standard means, and therefore currently 90% of the fabrics produced from filaments produced from the spinning of the mixtures with desired qualities.

Nowadays, created thousands of varieties of special disperse dyes. They allow you to not just colored cloth, but the real masterpieces with amazing iridescent color. The impression is created due to the fact that the paint does not stick to the surface of the filaments, as in the case of the same rayon fabric, and is part of the very fabric.

If necessary, use white dyes, resulting in a fabric almost perfect white color. Since acetate is very resistant to UV rays and very easy to wash, the durability of this cloth is many times greater than the rate for cotton or another natural fabric.

If necessary, use white dyes, resulting in a fabric almost perfect white color. Since acetate is very resistant to UV rays and very easy to wash, the durability of this cloth is many times greater than the rate for cotton or another natural fabric.

How is the molding

Most Often used in the production of a die having approximately 200 holes. If we get a thread plan to twist the thick fibers or ropes, the mixture is passed through a Spinneret with corrugated and convoluted walls. If we talk about the staple acetate fibers, their production does not differ from described above process.

The Feature is that individual strands emerging from the forming device, then gather into a bundle, which immediately cut into pieces of the desired length. In addition, staple fibers can be produced in the form of ribbons, which further cut into pieces of the desired length.

Basic properties of fiber

What are the main properties of acetate fibers? The thickness of the produced filaments in any case, ranging from 11.1 dtex X 25 to 16.7 Tex X 25 (No. 90/25— 60/25). If compared with viscose rayon staple fibers of the same thickness, the acetate yarn strength is slightly lower (by approximately 10-12%). But! If this tissue becomes wet (Yes, the same hygroscopicity 3.5%), the strength characteristics are reduced from 40-45!

Tensile Strength (elongation) is approximately 27%, but the elastic elongation is much higher than to repeatedly mentioned above viscose fabrics. It is because of this "acetates" very badly crushed and stuff from them for a long time look perfect.

Upgraded version

All of the above might give the attentive reader the idea that the fabric of this type too many flaws. This statement is quite true for the recent past, but today, with its production almost always used modifying additives, which have no chemical action on the acetate. The formula in this case looks like this: [C6H7O2(OH)3(OCOCH3)x].

In addition, today increasingly use directed heat treatment of the spinning mass: the molecules begin to form a more ordered structure. In the result, the acetate becomes much stronger and not so afraid of high heat.

Today, such qualities are characterized by fiber “salon”, produced by the type of staple fabric. It is very durable and elastic, possesses high durability and beautiful appearance. Empirically, it was found that a small amount of pyrophosphate of aluminium, added to the spinning mass, allows to obtain acetate, which is possible in any field where there is a risk of fire (curtains for theaters, for example).

Today, such qualities are characterized by fiber “salon”, produced by the type of staple fabric. It is very durable and elastic, possesses high durability and beautiful appearance. Empirically, it was found that a small amount of pyrophosphate of aluminium, added to the spinning mass, allows to obtain acetate, which is possible in any field where there is a risk of fire (curtains for theaters, for example).

Article in other languages:

AR: https://tostpost.com/ar/business/3067-acetate-the-production-of-acetate-fiber.html

BE: https://tostpost.com/be/b-znes/5422-acetatnoe-valakno-vytvorchasc-acetatnogo-valakna.html

DE: https://tostpost.com/de/business/5420-stickerei-die-produktion-von-acetat-fasern.html

HI: https://tostpost.com/hi/business/3068-acetate-the-production-of-acetate-fiber.html

JA: https://tostpost.com/ja/business/3067-acetate-the-production-of-acetate-fiber.html

KK: https://tostpost.com/kk/biznes/5424-acetatnoe-talshy-y-acetatty-talshy-nd-ru.html

PL: https://tostpost.com/pl/biznes/5427-w-kna-octanowe-produkcja-acetatnogo-w-kna.html

PT: https://tostpost.com/pt/neg-cios/5423-acetatnoe-fibra-a-produ-o-de-acetato-fibra.html

TR: https://tostpost.com/tr/business/5428-asetat-retim-asetat-elyaf.html

UK: https://tostpost.com/uk/b-znes/5426-acetatnoe-volokno-virobnictvo-acetatnogo-volokna.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

OOO "Feniks" - collection Agency: the staff and the victims

“Phoenix” − collection Agency, which reviews from victims are more often negative. It was created at the initiative of the Bank "Tinkoff". Despite the fact that the organization was registered as a separate legal...

Costs – costs costs of monetary resources that are required for production. For the company, such costs act as payment for the acquisition of factors of production. Costs are divided into fixed, variable and total. Fixed cos...

Is it possible to build lashes for pregnant women?

In the period of waiting for a baby each of the fairer sex, no less want to look beautiful and attractive. In pregnant women, accustomed to modern cosmetic procedures, many questions arise concerning the possibility of implementat...

Range is an integral part of trading. What is it?

If to speak in General, any assortment – a large number of goods collected together. There are various signs that they can be categorized. For example, products can be combined according to the manufacturer, the raw ma...

Incubation of duck eggs. Mode of incubation: table. The period of incubation of duck eggs

each species of birds their regimes of incubation. The first factor that has an impact on this – birds: waterfowl or land. Eggs duck and chicken differ not only by weight but also by the thickness of the shell, so for each t...

Administration – it is a system of specific actions aimed at the correct co-ordination and streamlining of all aspects of the system that allows you to do any steps more streamlined and efficient to achieve the highest...

Comments (0)

This article has no comment, be the first!