Now - 03:29:35

Types of solar cells and their characteristics

The Batteries on the solar cells are beginning to gain popularity among the population. They are mounted on rooftops, vehicles. Some of them are adapted even for electronics, a wrist watch. At the moment they have become a viable alternative of electric power or act as a Supplement.

How it works?

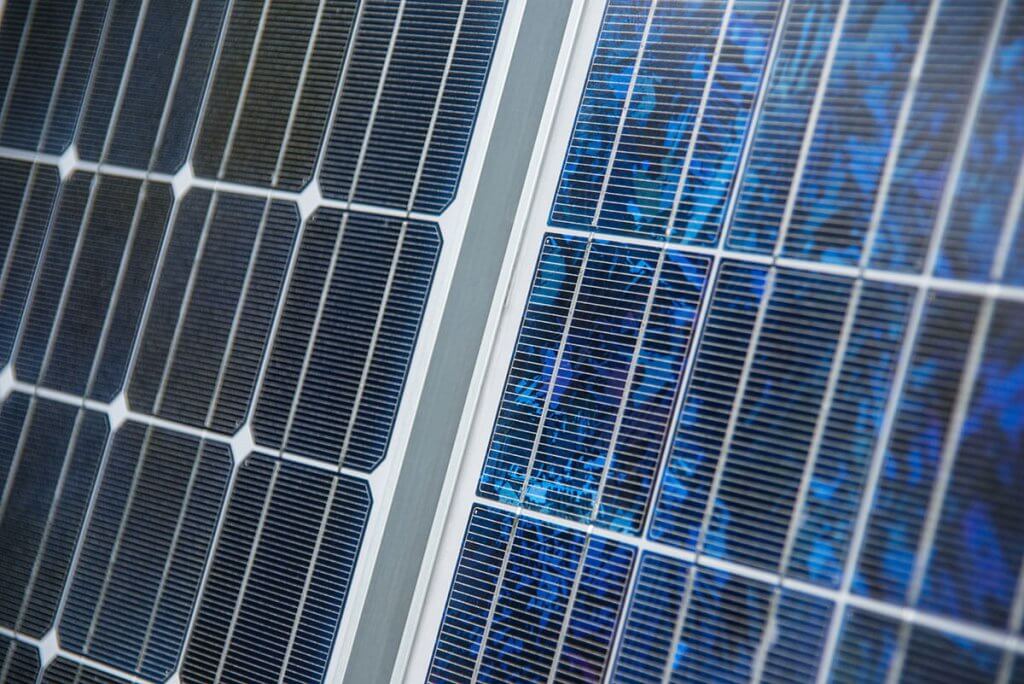

The Solar modules are the most important element in the photovoltaic system. They are panel, which includes solar cells made from silicon.

To generate electricity all these components are assembled into blocks, which are then upholstered laminated film – this is necessary for sealing. Then all fits in the frame. The device is simple enough, but to collect at home will be problematic. Alone is not possible to collect a photoelectric element, which cannot be said about the panel.

Types

The Batteries on the solar cells are divided into several types. Among them there are:

- Monocrystalline. In the manufacturing process used a material in the form of pure silicon. This framework allows you to obtain more efficiency from the work. Efficiency in this case varies from 15% to 20%.

- Amorphous-silicon. At the time of the production is used for the system – the evaporation phase. The silica thus coated with a protective layer. A number of advantages for silicon solar cells can be attributed to an acceptable value, which is obtained because of the simple technology used in production. Such systems are large in size. Efficiency varies from 5% to 8 %.

- Polycrystalline. This solar cell is produced on an amorphous-silicon-based. In the manufacturing process is not subjected to stretching. Has a low cost. Can be used not only at home but also in industry. Efficiency is from 10 to 14 %.

The Pros and cons of solar panels

Solar Panels consist of photovoltaic cells, which in the process convert the energy from the sun into electricity.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

A number of advantages can be attributed to the following:

- The battery design is quite simple, it is completely absent moving parts. The work is carried out consistently and without interruption, the trust level is high.

- Assembly work do not cause difficulty. Do not need to use expensive maintenance systems.

- Energy from the sun is immediately converted into electricity, additional time is not required for this.

- The Energy produced throughout the day while there is sun. In some cases, you can get electricity on a cloudy time, but the efficiency decreases.

- The lifetime is large, it is measured not by years but decades.

- In the production process using environmentally friendly materials that is considered very important in modern society, where there is a difficult situation with the environment.

Despite all the advantages, the work can meet and negative points:

- Semiconductors are made from silicon, have a high cost. This material is considered to be the main element in the entire system. It impacts on the cost of the panel itself, and the cost of the energy produced.

- Efficiency is low. To date, the power from the battery 1 square is approximately 120 Watts. This figure is so small that there is no possibility to use the electricity for lighting a small space.

- Obtaining electricity depends on the length of daylight, weather conditions and seasons. For example, in winter the level of energy produced is significantly reduced. This is due to the cloudy skies, fog and short daylight hours.

Where to use?

These panels are widely used not only in everyday life, in the process of life, but also in industry and in the production of:

- Them charge the batteries of electric domestic appliances;

- Made charging an electric vehicle;

- They can be used to provide electrical energy for the entire building;

- In some cases it is possible to use in some localities;

- From them you can get energy even in space.

All the energy that is produced during daylight is stored in batteries, after which the devices can operate even in the dark.

What is the working principle and the device?

Solar cells operate on the same principle as in the time of the first development. This principle is familiar to everyone, as it studied in the school curriculum, conducting physical experiments. Transistor, which was missing the top cover, contributed to the penetration of light on the transitions of p and n.

Once connected to a voltmeter, you can see that at the moment of impactsunlight was allocated a small amount of energy. Previously, scientists conducted experiments at work, have increased the area of the transitions. As a result, there appeared solar panels.

The Design of the solar system elements contains:

- Surface made from transparent glass. On it are the rays of the sun.

- Glass attached to the rigid ribs of the panel. They represent a plate made of metal, while at the same time function as a positive electrode.

- Solar chemical element. Type p silicon.

- Type of silicon n.

- Lower substrate of a metal, which is designed to function as a negative electrode.

You Should know that the energy from the sun is impossible to get throughout the day. The battery is not able to function at night. In winter, daylight is reduced. At such moments, the main unit requires the addition of energy storage.

In most cases the use of an electric battery. It is connected to the panel and stores the power generated, with the result that the work is carried out in the evening.

The Level of efficiency completely depends on the material used. For example, when using monocrystalline silicon, it is equal to nearly 20 %, polycrystalline silicon reduces this figure by 10 %. The level of efficiency can influence the smoothness of the surface, temperature of air, the location of the batteries to the sun.

What is the relevance of the use?

To date, the use of environmentally friendly materials is most important. Electricity that turns on the power – nuclear, water, thermal, constantly going up. This is due to the expensive production. In that moment, when it is used solar battery, people can rightfully consider themselves independent, even from the state, which provides electricity for use at an inflated price.

Once you spend a certain amount of money, then you can completely forget about the utility bill on the counter utilities. At a time when installed these panels, the transfer of the house. This includes not only light, but also heating, plumbing – hot water.

Radiation of sunlight – it is a great source to produce electricity. And most importantly – this source is free, clean and inexhaustible.

Stages of production of items based on a single crystal

Most solar cells are manufactured using polycrystalline silicon and monocrystalline silicon. The production process requires a lot of time, effort and funds.

The main stages of production on the basis of monocrystalline silicon include:

- Production of silicon. In order to obtain silica, use quartz sand, which contains large amounts of silicon dioxide. This sand goes through several treatment stages, which allows us to exclude oxygen. This is due to the melting at a high temperature with the use of chemicals.

- Get crystal. After cleaning, the silicon becomes transparent. Crystals begin to grow for the organizing structure. The process is as follows: the silicon pieces is placed in a crucible, is heated and subjected to melting. The molten mass was added the crystal samples, which are evenly distributed over the entire surface and begin to grow layers. This process requires much time, resulting in a homogeneous crystal of large size.

- Processing. This process starts with measurement and further processing of the crystal to give the desired shape. At the exit of the crucible, the crystal has a round shape, which is inconvenient for further use. For use it needs to be square. After the finished material treated steel wires using the wire it is cut on the same plate. The size of the plates varies from 0.25 to 0.3 inches. After that they are cleaning, checking for defects and the level of energy that can be produced.

- Development of the photovoltaic element. In order that the silicon had the ability to produce electrical energy, it adds boron to phosphorus. After processing, the phosphorus - free electron n-type, and the side with the boron does not contain these electrons and has p type. Thus, between the two sides appears a transition.

- The build Process. Initially, the plates are connected in a chain, and then into the unit. One plate has an average capacity of 2 V and 0.6 W voltage. Battery power depends on the number of cells. The voltage level produced by the sequence of connections. All elements and modules are connected in parallel to each other. All cells are covered with a special film, transferred on a glass surface and placed in a frame with rectangular shape. Once the module is ready, it is tested. After a full check it is ready for use.

Solar cells are interconnected in parallel, sequentially or in parallel series. The choice depends entirely on what level of stress is necessary to obtain in the process.

The production Process of polycrystalline silicon

The production Process of the module tothe basis of polycrystalline silicon in the same manner as when the single-crystal silicon. The difference is present only in cultivation. There are several methods, but at the moment, the popularity of only one – Siemens-process. The whole essence of the method lies in the fact that initially restores the precipitated silane and free silicon. This is done in collaboration with the special mixture, which contains the elements of hydrogen and silane using a temperature ranging from 600 to 1350 degrees Celsius.

In this way the process of production of solar panels.

How to make solar panels at home?

Many people tend to assume that batteries with solar cells with their hands going is difficult, even almost impossible. In fact, things are different. Make an effort going to need a lot, but the process is not difficult as it seems initially. The main difficulty which can be encountered in the process – it is collecting solar cell with their hands. If you manage to create such a mechanism alone, it will be possible to think not only about the rejection of payment for utilities, but also for the realization of their own business. At the moment, solar panels are very relevant to the sale of energy playing them. The most important thing – payment is made in one of the most stable currencies – the Euro. Is the production of solar cells is not worth attention?

In order to work with fotoacademie need to have skills and experience in this field. The first thing that comes to soldering and careful attention to all the elements. To work you need to have good soldering tool that is suitable for fine work. To create mono - and polycrystals will not work. You can use the finished workpiece.

Patacake

The First step is the selection of the necessary foliaceus. For battery life you can use silicon to poly - and monoacetate. The most important thing – to take into account the level of performance and nuance at work. For example, in monotoniko efficiency is higher, but in poliyacheykami lost considerable energy in cloudy time.

All cells are divided into classes. All of them there are four. Class a has the better quality with no defects. This class is used in the solid and large organizations, companies. Performance working high, but the cost is appropriate.

When the production of the batteries themselves, you can choose the class B. the Efficiency is lower than that of previous items, the cost is significantly different. Some organizations use this class in the manufacture of batteries to implement, which explains the low efficiency.

Some people buy all they need over the Internet shops. If you go to a specialty store, you can buy all the components at once. Then you won't have to wait for delivery.

Sets

For collecting the solar cell will not be enough only cells since they need some way to connect with each other on the scheme. This will require the use of guides and additional materials. That's why some manufacturers offer to buy the box set that already has all the material needed in the work.

In such a set may include up to 72 elements, conductors, bus, and diodes for the circuit and a pencil, which includes a special acid for soldering.

Some sets may contain the finished patacake to which the soldered conductors. To collect just enough to collect all according to the diagram and connect. This is the optimal alternative when solar cells to build solar panels are connected manually. The material is very small and fragile, which causes a number of problems in the process.

Pike

In that case, if all the material – elements and conductors were purchased separately, the entire soldering process of solar cells will look as follows:

- Conductors are cut to the desired length. It is best to do this work pattern.

- Conductors neatly stacked on the solar cell.

- In place of the soldering is applied, the acid and solder. To avoid bias on one end to put a heavy object.

- Wire you want to solder carefully. Since the cells are quite fragile, it is not recommended to influence them by force.

Such work is very laborious, not the fact that get everything done right the first time, you may need to repeat the whole process several times. If you examine the rules we can understand that the plated conductors made of silver calculated on three cycles of soldering. There are cases when the conductors are pre-applied solder, the manufacturer warns immediately. But it is best to apply it additionally. In the process, it is forbidden to put the solar batteries on top of each other, as you can damage them due to too much pressure.

Encapsulation

The Final step is to seal all elements. But before to start it is necessary to pay attention on the reliability of adhesions. To do this, use a multimeter. The test can be carried out after completion of all work, or during the whole process, after soldering each individual element.

Forthe sealing process is often used silicone sealant. First, he applied to the joints of the elements, and then the whole panel surface. For such work you can use a brush to apply it you need only to joints as it is possible to move the cell from place. Once everything has dried, you can close the cover.

Selecting a battery in the house

At the moment you can see the battery with two types of solar cells: monocrystalline, polycrystalline.

Each type has advantages and disadvantages in the work, you should be aware of before making a purchase.

Market Opportunities and production does not stand still, regularly there are novelties in the process of manufacture of which use different technologies. Before you make a choice, it is recommended to pay attention to the characteristics of solar cells: the efficiency for a battery that can store energy during daylight hours and to develop it in the dark. All of this information beforehand provides the manufacturer, they can be found in a specialty store. It's best to find online information or discuss with the experts which option is best.

Article in other languages:

AR: https://tostpost.com/ar/business/22825-types-of-solar-cells-and-their-characteristics.html

BE: https://tostpost.com/be/b-znes/40238-typy-sonechnyh-elementa-h-haraktarystyk.html

DE: https://tostpost.com/de/business/39782-arten-von-solarzellen-und-deren-eigenschaften.html

ES: https://tostpost.com/es/centro-de/39511-tipos-de-celdas-solares-y-sus-caracter-sticas.html

HI: https://tostpost.com/hi/business/24451-types-of-solar-cells-and-their-characteristics.html

JA: https://tostpost.com/ja/business/22369-types-of-solar-cells-and-their-characteristics.html

KK: https://tostpost.com/kk/biznes/40621-t-rler-k-n-elementter-n-zh-ne-olardy-sipattamalary.html

PL: https://tostpost.com/pl/biznes/42491-typy-ogniw-s-onecznych-i-ich-w-a-ciwo-ci.html

PT: https://tostpost.com/pt/neg-cios/42120-tipos-de-c-lulas-solares-e-suas-caracter-sticas.html

TR: https://tostpost.com/tr/business/37185-t-rleri-g-ne-pilleri-ve-zellikleri.html

UK: https://tostpost.com/uk/b-znes/41124-tipi-sonyachnih-element-v-ta-h-harakteristiki.html

ZH: https://tostpost.com/zh/business/33720-types-of-solar-cells-and-their-characteristics.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Discount rate as the analysis parameter investment planning

the Conduct of any activity is impossible without the implementation of a thorough financial analysis, which also includes investment planning, business planning for the future ongoing evaluation activities. The analysis of any of...

Every educated person needs to understand what the supply and demand in the market and how these concepts affect the price level. As you know, manufacturers are unable to provide an unlimited number of products and services, as po...

Dry alcohol – the history of the emergence and application of

Dry alcohol – solid, not giving smoke fuel, which is directly to the alcohols is irrelevant. This substance is produced most often in the form of large tablets, the burning time of the tablets is approximately 12-15 minutes....

Production capabilities: their characteristics

in the economy a direct impact from committed investment in assets associated with production, bears the name of manufacturing capabilities.the Main obstacle limiting production of opportunity, is such a factor as usual a lack of ...

Oxygen cylinders. Regular dressing - the guarantee of health and safety

To interest in scuba diving does not present unpleasant surprises, but brought only pleasure, you need to follow strict rules for the preparation of immersion in water. Correct filling of oxygen cylinders – this is one of th...

The depth of soil freezing is a very important indicator

Everyone dreams about their own home. The majority makes a decision about self-building a house on already existing property of the territory. Here it is necessary to consider the specifics of location of the site and the climate....

Comments (0)

This article has no comment, be the first!