Now - 00:21:45

What is dust?

Abrasive materials are characterized by their ability effective mechanical action. With their help, remove dirt, remove raids, produce clean surfaces of rust and paint. Work item, in fact, are abrasive granules, which can have different shapes and sizes. One such pellet is abrasive dust, which can have a plant origin or be the result of processing, waste, etc.

General information about the abrasive dust

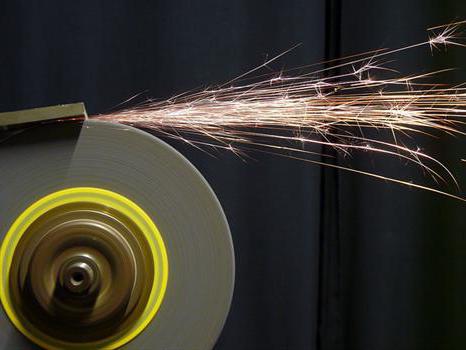

Dust can have different characteristics and origin, but in most cases it is an undesirable product of processing of metal and wood products. Typically, the abrasive powder is released in the process of performing grinding and polishing work. Dust may be generated and household surfaces, and in large volumes when performing operations on an industrial scale. In both cases, the metal abrasive dust is the result of the destruction of the primary processing of the material. Most of these wastes leave the grinding disk by mechanical action on the target work surface. It is not always the dust is a metal-usually this is a combination of compositions that include particles of the abrasives from the rocks.

Structure

The system is mainly subjected to items made of ferrous metal. It could be future pieces for machine tools and car components, and construction materials. The basis of any composition of such dust forms iron – 30 %. The second volume of the contents is usually aluminum oxide - alumina, although the quality may vary as well. To the secondary constituent element of abrasive powders include phosphorous, arsenic, Nickel, manganese, chromium, etc. a Lot depends on what the work surface interacted the dust abrasive. The composition of the emitted mixture often includes elements of scale, rust and old paint coatings. In fact, to combat such layers often used technique of abrasive removal.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Varieties of abrasive dust

Classification is based on several principles of separation of abrasive particles. They are largely dependent on the method of application of manufacturing material. For example, if you are using a grinding machine with a nozzle in the form of a circle, the dust can be called silicon. Also practiced the use of sandblasting machines that were originally used crushed particles of abrasive. They may differ in sizes and shapes, but their goal remains the same – removing from a surface unnecessary coatings or ensuring the smoothness of the workpiece. The end product of processing in this case will be the metal abrasive dust, but in a deformed fashion. It is important to note that, in contrast to silicon compounds, such dust can be used in further operations as used metal powders for grinding.

Features

The Parameters and properties of the formed dust are determined by the conditions of the operations and materials used. For instance, the machine produced machines requiring high-precision finishing of surfaces to the required geometric format. In this treatment between the rolled blanks and roll-formed large particle dust, the size of which can vary from 5 to 10 microns. Usually it is obtained by evaporation of the oxides constituting about 20% in mass. On average, these enterprises the dust emission is of the order of 200 g per 1 ton of processed metal. If the same applies in addition and scarfing, the amount of abrasive waste may be significantly increased. When performing grinding operations in smaller volumes formed by the abrasive dust has a fine character. Such dust particles according to their diameter are 0.5-1.5 µm. But do not think that the separation of the fine particles is safer than big. First, a large fraction facilitates the operation of extraction. Secondly, from a medical point of view, fine dust is more dangerous to the respiratory system. Now worth more to tackle the question of why we need to fight with the free allocation of abrasive waste in the process.

How dangerous is dust?

Without an effective dust extraction system production of metal dust will inevitably lead to its dissemination in the air of the working space. In such circumstances often develop occupational disease fitters. Such diseases include pneumoconiosis, dust bronchitis, asthma, etc. disease could be a consequence of regular lung irritation abrasive particles and from the processing tools, and the elements of the structure of the workpieces. Therefore, it is important to initially organize a system that will ensure efficient removal of abrasive dust directly in the production environment. Depending on the scale and conditions of work of such systems are organised on different principles. This may be a typicalindustrial vacuum cleaner connected to the grinding apparatus, and industrial ventilation.

Removal Methods

Small abrasives from machined using surface grinding machines material is usually collected and discharged in special tanks. It is enough to consider the channel the movement of dust. Most often the problem is solved with the help of planes, wetted with water. Water veil blows powder into a sump equipped with a filter. Then again cleaner water washes away portions of the deposited dust. For greater efficiency it is possible to provide the drain channel with a ventilation system that will prevent and accidental dispersion of fine particles. In construction often use the vacuum cleaner for grinding dust, which at the time of selection of the particles draws them in a special container, not allowing to fly. A more efficient system to deal with waste abrasive machining also involve the use of air flow. For example, in the development threads may be involved ejector, which is installed in the center of the body of the separator.

Conclusion

Production of abrasive particles is an inevitable phenomenon not only in the process of grinding and polishing. Even the typical metal cutting "grinder" promotes the formation of such elements. It is not always possible to provide a system through which the abrasive dust is removed automatically. Especially in a domestic environment when you perform one-time repair operations, specifically for it to acquire the same vacuum cleaner is impractical. In such cases, you should consider first and foremost means of individual protection of respiratory organs. With regard to the protection of room surfaces, it will be useful before beginning work, cover them with foil. And it is obligatory to arrange ventilation – even through the window into the street.

Article in other languages:

AR: https://tostpost.com/ar/business/12938-what-is-dust.html

BE: https://tostpost.com/be/b-znes/23168-shto-takoe-abraz-nyya-pyl.html

DE: https://tostpost.com/de/business/23173-was-ist-der-abrasive-st-ube.html

ES: https://tostpost.com/es/negocio/23193-qu-es-el-polvo-abrasivo.html

HI: https://tostpost.com/hi/business/12958-what-is-dust.html

JA: https://tostpost.com/ja/business/12962-what-is-dust.html

KK: https://tostpost.com/kk/biznes/23161-b-l-abrazivnaya-sha.html

PL: https://tostpost.com/pl/biznes/23116-co-to-jest-odporna-na-kurz.html

PT: https://tostpost.com/pt/neg-cios/23117-o-que-poeira-abrasiva.html

TR: https://tostpost.com/tr/business/23167-nedir-z-mpara-tozu-mu.html

UK: https://tostpost.com/uk/b-znes/23147-scho-take-abrazivna-pil.html

ZH: https://tostpost.com/zh/business/13708-what-is-dust.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Assessment of efficiency of investment projects is important

the level of profitability of activity of the enterprise is affected by how quickly and correctly the entrepreneur is able to make decisions regarding the investment of available funds. It is therefore important to assess the effe...

Paul Will tattoo with kids and not only

Paul Will tattoo which often is the interest of the fans – a well-known entertainer. Also special attention is paid to his relationship with Laysan Utyasheva. Pair twice new parents about what a celebrity does not get tired ...

What schedules are for enterprises?

What are the work schedules in the enterprise or in the company? This question asks every person that wants to optimize their working activity because of certain reasons. The article will answer the question.General informationthe...

Production costs and their Classification

production Costs and profit.The production costs understand the cost of creating the product. The costs include costs of raw materials, wages of employees, depreciation and other expenses related to the activities of the ent...

How to make a doll refrigerator with his own hands

Parents of children in the modern time knows how much on the shelves of various toys and accessories for them. Girls love to play with dolls. Especially if the baby has a Barbie house and some furniture for her. All parents, witho...

Dairy plant - design and equipment

the share of milk production accounted for 1/3 of the total food agriculture of the country. Milk and its products are an integral part of the diet of children and adults. It is therefore very important to ensure they have the pop...

Comments (0)

This article has no comment, be the first!