Now - 06:41:14

Welding of optical fiber: the description of technology, equipment, prices

Welding optical fibers. How does it happen? And what is it? Here at once it is important to note that the process of welding is not as it used to.

General information

Fiber optic splice, or rather its lived among themselves is carried out by heat treatment under high temperature. To date, the development of technology allowed us to fully automate this process. It carries out the welding machine in automatic mode. Speaking of welding optical fibers, you need to understand that the whole process is automated by the robot, which is equipped with an automatic control system. However, it should be noted that the overall control of the robot performs all the same person (the operator). If we talk about the dimensions of this device, it is of medium size - 150х150х150 mm.

Device for welding

The Modern devices consist of several main parts.

- The First main node is a power supply.

- The Second main node electronic unit, which consists of items such as the motherboard, the voltage Converter and a few more details.

- Mechanical node is an electric actuators, a carriage, an optical system, etc.

The Full name of this equipment is a welding machine for welding optical fibers. Further to this, most often, add the name of the firm, which is engaged in the manufacture and labeling of the device.

An Important detail and the main difference between each model apart lies in the fact that each of them has their own software. The interface, on the contrary, more often almost identical and consists of such components as the monitor, keyboard and menu. Another feature possessed by practically all devices is a division of the menu into two parts. The first part is called open and is open to all, the second part is a secret, it is intended for use only by employees of the company that manufacture these devices. Most often, this section closes with a password that is a combination of keys. It is worth noting that the price of welding the optical fiber will fluctuate depending on what actions you need to perform.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

The First stage of welding of fiber

If we talk about the process of welding the fiber, it consists of several stages:

- The First step is cutting the optical cable. It is understood the following: eat the outer shell, eat the inner shells (usually two, for best protection of the cable). In order to remove the outer shell often use a special tool. If the cable is divided into several modules that cover each separately lifted by the stripper.

- Cleaning of the fiber material hydrophobic type. Quite often, to preserve fiber integrity, use the filler hydrophobic type. For this purpose, a colorless gel. To remove it use a special solvent "D-Gel".

Further work

Fiber-optic splice after completing the first two preliminary stages, proceeds as follows:

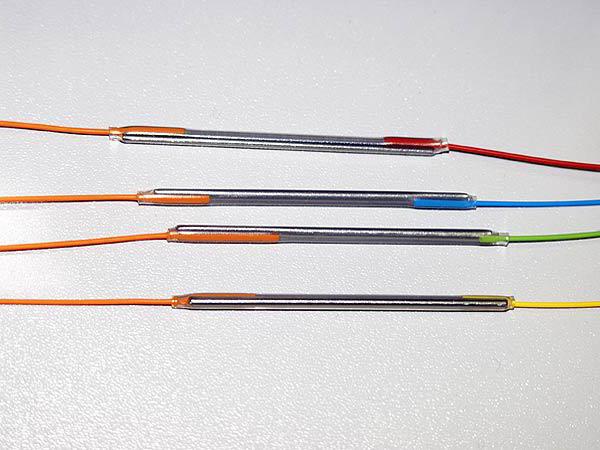

- The fibers of one of the cables necessary to put such a thing as CSR. This special liner kit to protect the connections. This kit consists of two heat shrink tubing, and power of the rod.

- Using the stripper, remove the protective gel on the ends of the optical fiber (approximately 2-3 cm from the end). Before moving to chipping, you need to wipe cleaned the tips with alcohol.

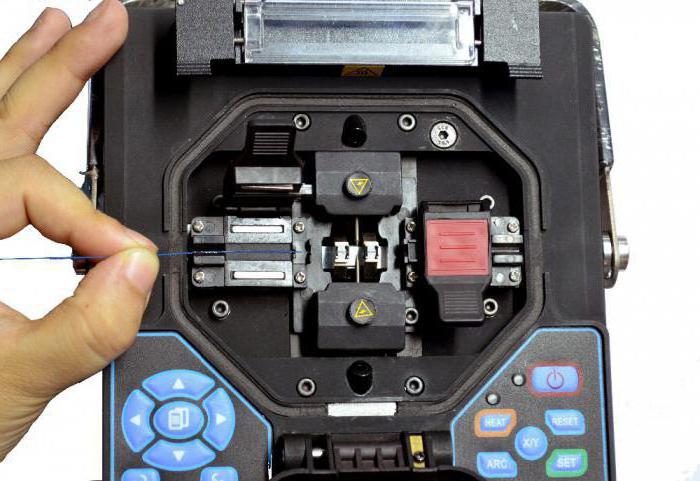

- After all the preparatory procedures, you can go to chipping. To carry out this operation, you must have a precision cleaver. If we talk about the plane of cleavage, it should be exactly perpendicular to the axis of the fiber. The maximum deviation that is allowed for each chip is 1.5 percent.

- To start the welding process of the optical fiber should be placed in the clamps of the welding machine cleaned and cleaved fibers. The role of the clamps at the hardware are V - shaped ditches that hold and serve fiber during welding.

Basic steps of welding

The Price of welding optical fibers is quite large, and therefore it is better not to make a mistake during operation, especially in later stages.

- First main phase welding is the adjustment. Under this concept understand the process of connecting optical fibers together. This would require a microscope, and the process is carried out by motors. If we talk about modern devices for welding, they execute this function in automatic mode.

- Next comes the electric arc, which heats the ends of the fibers to the desired temperature, leaving microtutor between them. The process of bonding the fibers is relatively slow. Combine the ends of the product with the help of the motor holder.

- Pretty big plus to use the device for welding optical fibers is that he estimates the attenuation in the weld area. In addition, it automatically performs quality control of the fiber connection by means of a mechanical influence. In other words, ittest for the gap.

- An Important caveat. Before you start welding on one end is worn, CSR. After completion, the casing is moved manually by the operator at the place of work. As such, the cable must be placed in a thermal chamber in which the process of thermo-shrink sleeve.

- The Last stage is laying in the splice cassette, the optical coupling or cross-country, welded and lined with fibres.

Considering the entire process, it becomes clear why the price of a welding optical fiber is quite large.

Equipment jointer

Welding machines for welding of optical fiber is one of the most expensive devices which may have a jointer. The high cost of this equipment is that the instrument takes care of all operations concerning welding of optical fiber. All that remains is the person (operator) is to prepare the cables, lay them in the car, and then get to wear the sleeve and placed in a thermal chamber.

Getting started and summary unit

Welding machine for welding of optical fibers operates on the following principle:

- To get started you need to lay the cleaned and cleaved fiber into the equipment. It is important to remember in advance to put on the sleeve.

- Next, click (if auto process does not begin) and the device will begin to bring the ends of the fiber until then, until you see them in the optical system. It consists of cameras, microscopes, and several mirrors.

- At the moment when both ends will be in the field of view of the system, the device delivers a small electrical arc. The main purpose of arc is to blow away microbalance that remain on the surface, despite any most careful rubbing. Also, some believe that it's a little aplause ends, thus preparing them for welding. However, it is important to know that if the fibers remained at least a drop of gel, grease from fingers or any other item of similar type, due to the impact of the arc he will be baked, and so that to remove him will not succeed, will have to redo the chip.

- In that case, if all the chips are clean and nice, will begin the process of reports involving precision motors. If something is wrong with elements of adhesions, the machine will notify the operator about the alarm, the message on the screen, and the process reports will not start.

The Principle of welding on the unit

After completion of the training and details of the fibers, there is a direct cooking process.

- Both ends of the cable are reduced very close to each other. When the motors are switched off, the work enters the main electric arc of a great power, which for a second or two heats and melts the ends of the fibers. When the arc turns off, the motor lead ends, soldering them together. It is worth noting that the place of work arc, that is, the weld cools down almost instantly.

- The Device is in automatic mode checks the quality of welding on clearance. If the weld is good, it almost should not be seen. Also this equipment keeps variables such as date, time, and the attenuation of each of the conducted process. The welds counter is increased by one unit. It cannot be reset to zero.

- As mentioned earlier, the unit self test for a gap, however, when training welding optical fibers, experts recommend to disable it, as it can ruin still hot from welding.

The Last steps is putting on the sleeve on the place where he was welding, and place the cable in a heating furnace.

Manufacturers and prices

Today we can say that of the most common models are devices from the company Fujikura, Sumitomo. These companies are Japanese manufacturers. Second place goes to the Chinese company Jilong. If we talk about the spread on the territory of the Russian Federation, "fudzhikura" the greatest demand.

Price of machine for welding of optical fibers, which can be used for welding of the most important lines is in the range from 120-130 thousand rubles up to 300-350 thousand rubles. Lower cost for the Chinese manufacturer. The most expensive steel units of the Japanese manufacturer.

Pricing optic fiber splicing

If we talk about the cost of services on welding of optical fiber, it is necessary to know exactly what work is included in the costs. Most often, they list like this:

- Cutting and cleaning of a cable;

- Welding

- The Assembly of the cassette and laying fibre;

- Consumables.

This is a standard of operations that are performed in any case. Next, the separation of the cost of welding the optical fiber comes from the number of strands in the cable. If you want to work with the number from 32 he lived, for the connection 1-fiber would have to pay about 250 roubles. If the total amount is in the range from 1 to 32 fibers, the cost per connection of each will be 300 rubles. There are smaller limits, for example, from 1 to 8 fibers will cost 500 rubles for each core. 9 to 16 - 450 rubles. It is important to understand that the cost of welding the optical fiber is averaged and each office has its own policy evaluation of services.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Beekeeping in Tatarstan: features, facts and reviews

Active development of beekeeping in the Republic of Tatarstan in the first place is due to the presence of plants, the pollination which occurs by wind. Today Tatarstan takes leading level in the Russian Federation in the field of...

A chain of electronics stores Re:Store Shop: reviews, addresses of shops in Moscow.

One of the main Hobbies of modern people in the European countries and the USA, the equipment manufactured by American company Apple. To date, worldwide sold a lot of copies of phones, tablets, laptops and other accessories all cr...

Inverter voltage stabilizers for home: review, features and principle of operation

Fluctuations in the parameters of the electrical network are often found in the domestic environment, where there is no specific protection in the form of stabilizing equipment. Voltage drops – the most dangerous phenomenon,...

Maynskaya HPP - little helper energy giants

If you carefully look at the Yenisei river on the map, it is easy to see Yenisei cascade of hydropower plants. Very important step is Maynskaya hydroelectric, located in Khakassia, in the neighborhood of village lane.Tasks Mainska...

Band saw blades today are becoming more affordable for the average consumer, but to meet them often at the enterprises for carpentry and making furniture. If you want to buy such equipment, the first step is to understand the mode...

Excavator EOW-4421, main characteristics

Automobile plant in the city of Kremenchug produced a simple and reliable trucks with two or three axles. Variants with rear-wheel drive was widely used in the civil service as a flatbed trucks, dump trucks, chassis for installati...

Comments (0)

This article has no comment, be the first!