Now - 15:48:51

AGM technology in batteries

Batteries are used in many industries, but the mass consumer closer vehicles. And in this sphere the most evident weaknesses of such batteries. Problems in the operation of batteries are due to the nuances of ergonomics, maintenance and optimal reliability in different applications. In this part of drawbacks have been minimized by using Absorbent Glass Mat (AGM) in 1970. A new approach to the organization of the internal space, associated with changes in the characteristics of the electrolyte, which is relevant to our days. Moreover, AGM technology for all time of its existence, has undergone many adjustments and today allows you to develop batteries with a fundamentally superior qualities. However, not spared these batteries and the disadvantages.

General information about the technology

The Peculiarity of this technology is driven by the principles of the so-called associated electrolyte. So, if the classic batteries as the active substance is a liquid electrochemical filling in AGM systems use a dense electrolyte. Accordingly, this provides at least increased protection against vibration. In terms of everyday treatment of such units many have noted the convenience and reliability. But this is not all of the features that characterized the AGM technology. Absorbed electrolyte which is most often used in such batteries itself has a considerable number of advantages. In practice, use is temperature resistance and ability to withstand a large number of charges. The implementation of the same concepts associated electrolyte requires special device casing and internal filling.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

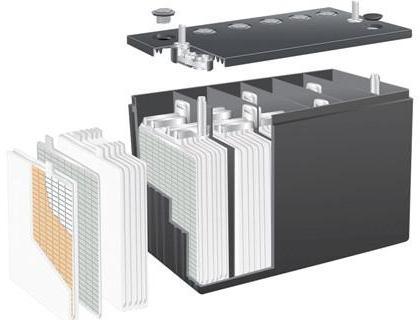

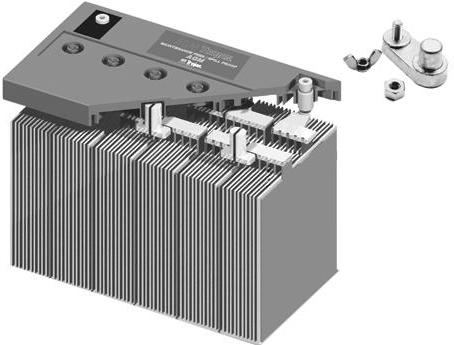

Block Design

The Housing is made of durable plastic, which houses a set of plates-electrodes. As a rule, the latter are made of lead, and that makes such designs from classic blocks. The main difference lies in the properties of the electrolyte, which is represented by the water-acid solution. It is a kind of acid, which fills the space of the case to ensure the subsequent reactions between the electrodes. In fact, the difference is due to the fact that the filling is not liquid, but solid state. Usually manufacturers use to ensure this condition, the microporous material based on fiberglass. It is impregnated with the electrolyte and thus form a tight bond between the internal components of the unit. The filler acts as a separator, not allowing the solution to spread. However, AGM technology may provide other ways of dense bundles of electrochemical substances, but the method remains the same – to ensure the reliability of the content of the active element without losing the basic functions of the battery.

Types of batteries AGM

Battery Models of this type are made in flat or coiled forms. This refers to the device electrodes. The spiral components are characterized by extensive electrochemical surface contact, which in practice increases the short-term ability to provide large currents. In addition, many motorists have noted the rapid replenishment of energy potential. But, on the other hand, the model with flat spiral electrodes benefit from a balanced the specific capacity of the battery. The same qualities, by the way, there are different gel blocks, and traditional lead-acid. With AGM technology the planar configuration, only optimize and allowing in established format to ensure the highest performance of the battery.

The Similarities with GEL technology

This is a group of gel batteries, which are also developed in accordance with the concept of the associated electrolyte. Only in this case, uses a different principle of the viscous filling. This applies to silica gel, covering the entire space of the block. As the AGM technology, the method of manufacturing GEL batteries provides resistance to vibration and reliability of electrochemical toppings in General. In this respect, the main advantage of gel batteries is to eliminate the risk of circuit. The tight fitting of the electrodes does not allow them to deteriorate, and the electrolyte also effectively cope with its function, interacting through the pores of the filler.

According to specialists, this kind of model is able to withstand about 1200 charge cycles. Budget devices allow you to charge up to 500-600 times. Similar indicators reaches and AGM technology. The advantages and disadvantages of both structures are largely similar and consist in features of interaction of the electrodes and the electrolyte. But there is also a difference in the operational nuances which are noticeable only on the practical application.

What is better – AGM or GEL?

For starters, it is worth emphasizing that the gel devices are more expensive models AGM, although this is not talking about their obvious advantage. So, to give preference to designs with absorbed electrolyte is for those who want to be confident in the durability of the filling to the high levelpower. In addition, these units benefit from quick replacement of the power supply. At the same AGM technology and GEL about equally consistently held the charge – in any case, if you compare models from the total price of the group. As for the benefits of gel elements, they better manifest themselves under high loads – for example, after deep discharge or when there is external electrical interference. Add to this the rigidity of the filler, which does not allow to physically destroy the stuffing, while maintaining the integrity of the same electrode. Gel model in the latest versions are designed to strengthen it strength quality, but progress in this direction prevents the inevitable lowering of the electrical properties of the block.

Technology Advantages

If you compare the advantages of the technology on the General background of batteries, on the foreground there will be no need to maintain. Next, you can already emphasize the dignity that extends to all devices that are made on the basis of the associated electrolyte. It's a sealed design with a valve adjustment, which minimized the risk of acid leaks. That is, it speaks to the reliability of the unit from the point of view of physical treatment and its environmental safety. This property, incidentally, are characterized by costly and branded batteries and low-end models, poorly manufactured. AGM technology maximum protect inner filling, which also contributes to higher efficiency of electrochemical processes. Here again you can return to a large number of charge cycles, rapid energy replenishment and stable operation of the electrodes.

Disadvantages

Most of the disadvantages possessed by the batteries of this type that apply to all lead-acid device. For example, it applies great weight to the toxicity of lead oxide, as well as restrictions on the organization of the storage conditions. In particular, the manufacturers do not recommend storing the blocks in a discharged condition. Besides, contrary to popular belief, experienced motorists say that in terms of frost manifested a drop in performance. This refers to the voltage fluctuation, which is usually reduced. Also, many point out the impossibility of recovery of the element after discharge. This is another point on which AGM technology is inferior in reliability to the development GEL. However, subject to even the General rules for the use of such batteries, such troubles were entirely avoidable.

The Rules of operation of the battery

To prevent sulfation of the batteries is recommended to always maintain their optimal charge. As the loss of capacity is reduced and the working life of the active elements. Also it is impossible to prevent short circuits in the terminals. Although the developers of AGM batteries working hard to improve the reliability and functional body parts, it is important to observe the correctness of external connections. By the way, this is especially true for operations in which repaired the AGM batteries. Manufacturing technology of batteries of new generation increases and the mechanical strength of the body, but also taking into account this aspect should not unnecessarily rely on resistance applied to the plastic shell. Opened AGM battery is no less dangerous than traditional lead-acid units.

Applications of technology

Of Course, modern batteries with improved performance characteristics can be used not only in cars. Products created on the basis of AGM technology, are utilized in power supply systems in the stations public service in the areas of telecommunications, etc. the Possibility of Autonomous power supply is also in demand in medicine – to maintain efficiency of the equipment in emergency situations. But as the AGM technology in batteries, does not exclude the use of heavy toxic and hazardous metals, manufacturers also impose restrictions on their operation.

Manufacturers

The Domestic battery market is saturated with models of a different type, among which the elements of the AGM. In particular, the initial segment represents products from firms "Ventura", "Optima", as well as some modifications of the line "stinger". However, most quality batteries with AGM technology, according to many motorists, offer manufacturers “Delta” and “VARTA". Moreover, in the collections of these companies, you can find different modifications of the blocks for any inquiries.

How much is a AGM battery?

Much depends on the technical characteristics, quality of materials and capacity, but on average, prices range from 10 to 20 thousand rubles, The cheapest battery of this type cost about 5-6 thousand If sold model for demanding electrical car, you can access the segment from 20 thousand just as many are high-quality and reliable AGM batteries. Technology organization of the contents of the absorbent electrolyte in this price level are more profitable, though also not exclude the possibility of defects typical for the General class.

Conclusion

The Emergence of advanced technologies in different fields often causes a stir in the market, but eventually everything returns to normal and the consumer still prefers the traditional products. It is for this reason that developers of new solutions in advertising focus on virtues, not always fully disclosing the drawbacks. And in this case, but experienced motorists and just experts familiar with the pluses and minuses, which gives AGM technology. Lead-acid batteries, even with a dense electrolyte does not cease to be sensitive to power surges, require compliance with the same security measures and thus are not cheap. However, in some cases, this option itself is fully justified. AGM batteries meet the needs of those motorists who are guided by the mechanical strength of the battery, its durability and performance. But to preserve these qualities for many years can only be subject to the rules of operation of the battery.

Article in other languages:

AR: https://tostpost.com/ar/business/21883-agm.html

BE: https://tostpost.com/be/b-znes/39389-tehnalog-ya-agm-akumulyatarnyh-batareyah.html

DE: https://tostpost.com/de/business/38901-agm-technologie-in-batterien.html

ES: https://tostpost.com/es/centro-de/38680-la-tecnolog-a-agm-bater-as.html

HI: https://tostpost.com/hi/business/23480-agm-technology-in-batteries.html

JA: https://tostpost.com/ja/business/21477-agm.html

KK: https://tostpost.com/kk/biznes/39774-tehnologiyasy-agm-akkumulyator-batareyalarynda-y.html

PL: https://tostpost.com/pl/biznes/41513-technologia-agm-w-bateriach.html

PT: https://tostpost.com/pt/neg-cios/41159-tecnologia-agm-em-pilhas-de.html

TR: https://tostpost.com/tr/business/36321-teknoloji-agm-arj-edilebilir-piller.html

UK: https://tostpost.com/uk/b-znes/40230-tehnolog-ya-agm-v-akumulyatornih-batareyah.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Kenes Rakishev, Kazakhstani entrepreneur: a biography, personal life

Kenes Rakishev, whose biography is described in this article, is well - known Kazakh businessman. At the same time it – the holder of the basic package of shares of the company «Kazkommerzbank” and venture invest...

Where's the best fish market in Russia?

someone Who likes to go to the market, for others it is a handful, but most people agree that it is a necessity to select fresh food at low prices. At the same fish market – is a separate category. Even in the major cities o...

Online shop "the Labyrinth": the staff

Search employer - not a simple one. Especially in Russia, where citizens leave very mixed reviews about those or other chiefs. You have to carefully look at the firm before you contact her for future employment. Today attention wi...

Flammable gases: the names, properties and application

Combustible gases – substances with a low threshold of heat of combustion. It is the main component of the gaseous fuel which is used to supply towns, industry and other spheres of life. Physico-chemical characteristics of t...

Industrial parks are areas for placement of new productions. Create, manage, and service

to place new production on-site, which provided infrastructure and energy, especially organized industrial parks. This education must be provided with all necessary conditions of administrative-legal plan. It is managed by one or ...

The main purpose and types of warehouses

the Existing industrial and commercial process could not do without such an important object as a warehouse. In the logistics organization is one of the conditions for proper organization of the movement of logistical supplies, pr...

Comments (0)

This article has no comment, be the first!