Now - 15:49:33

Brass fittings the types, purpose

When posting the pipelines often need to be connection parts to each other under an angle, creating branches, bends, or transitions to a different diameter of the pipe. For these purposes, use special accessories fittings. They come in copper, steel, bronze or cast iron, but the most popular are the brass fittings. Bronze counterparts of similar properties, but is less durable due to the absence of zinc. Of course, stainless steel products brass stronger and less prone to corrosion and deformation, but they are much more expensive to produce and require a substantial effort during installation.

Material Properties

Brass is an alloy of copper and zinc in varying proportions with the use of additives. It was first produced in 1781 in England, although the connection of copper with zinc ore has been used since the times of Ancient Rome.

Brass do not only such mundane things as fittings. It is made of, for example, the monument to Minin and Pozharsky on red square, although for a long time it was believed that the statue is made of bronze. For a long time in Russia and Europe, brass was also used as imitation gold.

The Material has high ductility and low thermal conductivity that causes high popularity of brass fittings.

Depending on the proportions of the alloy melting temperature of the material is from 880 OC to 950 OC, and a density of from 8300 to 8700 kg/m3. Brass is resistant to welding with other metals - both arc and gas.

What are the additives?

As alloying elements that increase the useful properties of metal are used the following substances:

- Iron - reduces graininess material and adds hardness.

- Tin, Nickel, aluminum and silicon are used to increase resistance to corrosion and friction, as well as the salts. Silicon also imparts additional hardness.

- Manganese increases the resistance to high temperatures.

- Arsenic does not give the water to wash the zinc alloy.

- Lead is used as a "lubricant" component, it facilitates machining of the brass and reduces tool wear during the cutting process, and also gives the smoothness of the surface of the metal. Lead also reduces the expansion of brass by heat.

Brass with zinc content more than 15% when stored in a humid environment prone to spontaneous cracking. To avoid this, it was calcined at a temperature of about 300 OC, which allows to reduce the residual stresses without loss of strength.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Supplement of 0.5% of aluminium gives the brass a Golden color and high resistance to corrosion in the open air, so the composition is used as a substitute for gold in artistic works.

Brass containing 1.5 % tin, used in sea shipbuilding, as perfectly resists sea water.

Alloy with high lead content used in the manufacture of watches and in the automotive industry. Adding only 3 % of lead allows to obtain a very clean surface during processing.

Corrosion protection

Compared to copper brass fittings have less resistance to corrosion that kompensiruet special protective coating. Mostly this applies to a galvanic coating of Nickel and chromium.

Chrome plating is of two types: brilliant or matte. The first type is characterized by strength and lack of time, second better treatable. The chrome-plating thickness is 0.33-1.5 microns.

Nickel plated well polished and protects brass from corrosion, has a low porosity. Apply a layer of 12,5-15,5 µm.

If the coating will be thicker than the recommended values, it threatens his cracking and loss of functionality of the product.

Chrome and Nickel-plated brass fittings look very nice. They will not spoil your view of the interiors of the house or apartment.

Varieties of brass fittings

To Classify these pipeline components is possible in two basic signs - application and mounting. Use range brass fittings, great sleeves, bends, tees, crosses, and so on.

By way of attaching the fittings are detachable and permanent. Used in pipelines, involving periodic repair, maintenance, or design changes. Detachable fittings are easy to install, but they require additional sealing. Permanent joints are used where pipeline access is blocked - for example, for the device warm floors.

Branches

Used in cases when you need to change the direction of the pipe at a certain angle (usually 45 to 120 degrees). Other names of this parts - brass corner fitting or an elbow.

Sleeves

This is a small pipe segments with external threads designed to increase the pipe to the required length. Standard size sleeves - 10, 15 and 20 centimeters, but there are some very short "barrels".

The Sleeves is also used to connect two fixed pipes. Thread in this case is done with one end long and the other short. Roundup screwed with one end into the fitting of the first connection and then connects to a second using the clutch, which is pressed by a nut.

Tees

These brass fittingsdesigned to create branches from the main pipeline. Depending on the angle at which you want to branch, there are straight (at 90 degrees) and oblique.

Bandwidth is divided into ravnoprohodnye and transient. First, all three outputs made of the same and divide the flow into equal parts, while the second one is to create a branch of a smaller diameter.

Cross

This brass fitting on the device like the previous one. The difference is that the crossbar provides a branch from the main pipeline in two directions. As a rule, brass crosses are straight, there are bends are made at an angle of 90 degrees. Used crosses, and tees most often when installing heating pipes from low pressure polyethylene (HDPE).

Overlay threaded

Mainly used for installation in pipe measuring devices - most water meters or heating. Is a short length of pipe with internal threads at one end and external on the other. Is installed through a tee. Overlay threaded is also used when it is necessary to reduce the diameter of the internal threads of the pipeline. It is screwed into the pipe end with internal threads and it is screwed into a segment of smaller diameter.

Other types

- Plug - used for sealing of one end of the pipe.

- Fitting on one end has external thread, the other is a special "brush" to attach to a brass hose fitting.

- Nipple - a short pipe fitting with two outer threads. Intended for connecting two pipe ends.

- Nut - designed for the same purpose, and fitting, but the thread is not external, but internal.

Threaded brass fittings

This is the simplest kind of detachable fittings. It is the most simple and popular. For the installation does not require special skills or special tools - enough wrench or a maximum of two.

A Significant disadvantage of threaded fittings that often have to condense connection with various supplementary materials - plumbing filament, tow, FUM tapes and pastes. Sealing materials have a certain lifetime, so such compounds should be monitored periodically, to improve or even rebuild upon detection of a leak.

Threaded brass fitting may have an internal or external thread, and the one and the other at the same time. With it, you can only connect a metal pipe, as necessary for joining the thread.

Brass compression fittings - another subspecies of detachable connections. Their use is not necessary to use additional sealing materials, since the sealing parts are already part of the product. One of the important advantages of compression fittings is that they can be used to connect any pipe, without taking into account the material and the diameter of the connections are made in the range 16-110 mm. Other advantages of these compounds are:

- They do not require constant monitoring of leaks and periodic pull-UPS;

- Designed to withstand high pressure;

- Long service life;

- Easy installation;

- Mounted pipes can be made of any material: steel, plastic, HDPE, copper and so on.

Brass Compression tube fitting consists of the following parts:

- Case with rubber gaskets at the ends;

- Nut;

- Crimp a ring that the nut is compressed and ensures sealing of the connection.

Compression fitting - pretty much a universal connection, it allows you to mount the piping under the ground and even under water. The only limitation is the temperature of the flowing in the pipes shall not be above +40 OC.

Since the pipe material is unimportant, very popular in the installation of domestic, commercial and industrial piping use brass compression fittings for HDPE pipe 32 mm, as well as plastic.

Fittings

This is the new type of fittings that have become a real salvation for professional plumbers and plumbers. The ordinary man in self-Assembly pipeline (e.g., country) to use press fittings does not make sense. First, for their installation need a special tool compression pliers that are available for one-time work unprofitable. Second, a press-fitting connection all-in-one, so in case of any error the item will have to throw away and buy new.

Professional plumbing brass press fittings, on the contrary, greatly facilitate the work, as their installation is much simpler and faster than conventional compression. The connection has higher reliability. It is well suited for mounting of hidden pipelines that are often required in everyday life - for example, when installing a washing machine or floor.

The Press-fitting consists of the following main parts:

- Brass body - its form depends on the purpose of the fitting (tee, coupling, nipple, etc.);

- Sleeve - the main component of the press-fitting, made ofstainless steel, it is subjected to crimping during installation of the fitting, maintaining the shape given to it and ensuring the tightness of connections;

- Clip - plastic part, plays the role of the dielectric;

Crimp brass fittings, there are significant advantages:

- These compounds are very durable - can withstand pressures up to 10 atmospheres;

- Producers declare service life of joints for about 50 years with proper installation;

- When properly installed fittings do not require periodic inspections;

- They are ideal for heating systems and hot water supply as resistant to thermal stress.

The disadvantages of press-fitting is that to dismantle them only with a piece of pipe to break them is impossible. Reuse also eliminated.

In addition, the installation of the press-fitting requires some skill - if you strongly clamp connection, it can prohoditsja and cause crash.

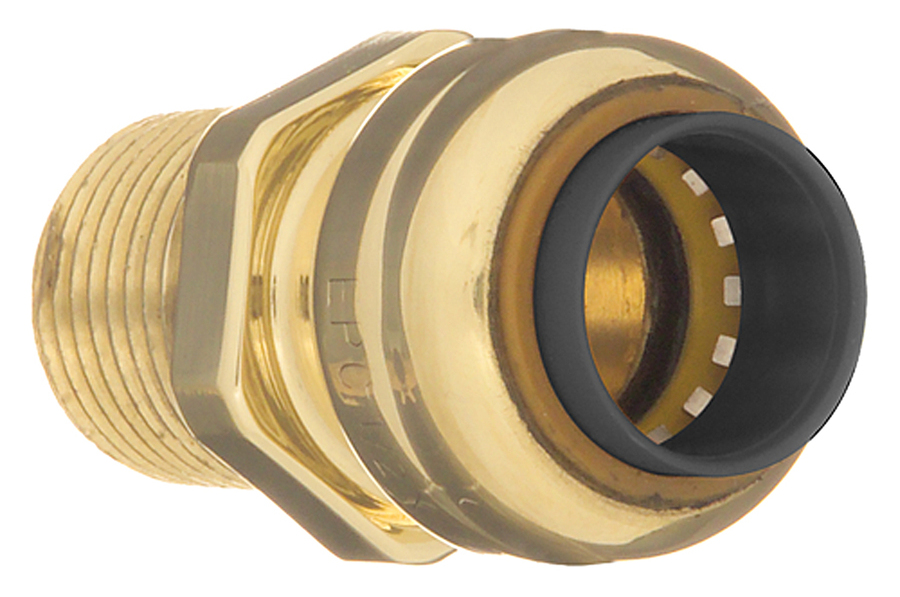

Push fittings

This kind of connection is relatively recent, but it is very promising because of extreme ease of installation. Designed these brass fittings for HDPE or metal pipes. No special tools are required and the connection happens almost instantly. The end of the pipe is simply inserted into the fitting - fixing automatically. The connection is extremely reliable, it can be concrete and bury in the ground. While push fittings refer to detachable connections - after dismantling them can be reused.

Device push-fitting the following:

- Brass body of a particular form, depending on the destination connection;

- At the ends of the shell are fittings with o-rings provide protection against leaks;

- Inside the housing is the collet engaged in the capture and retention of the end of the pipe to monitor the pipe inlet in the grip is a special observation hole.

All the elements of the push fittings are made entirely of brass, without the use of plastic, which increases the reliability of the design. The compound withstands temperatures up to 95 OC and pressure 10 bar. Service life - more than 50 years.

Installation of push-fittings are very simple. It is the perfect solution for pipe-laying with their hands, especially considering the fact that the connection is tight, reliable and does not require constant monitoring of leaks. The only trick when installing is that the end of a pipe must be perfectly calibrated. Need smooth and clearly perpendicular to the longitudinal surface of the pipe cut, otherwise the connection will get loose. Professionals use a special tool calibrator end. The alignment of the slice manually will require some more time, but this is more than kompensiruet speed of installation and reliability.

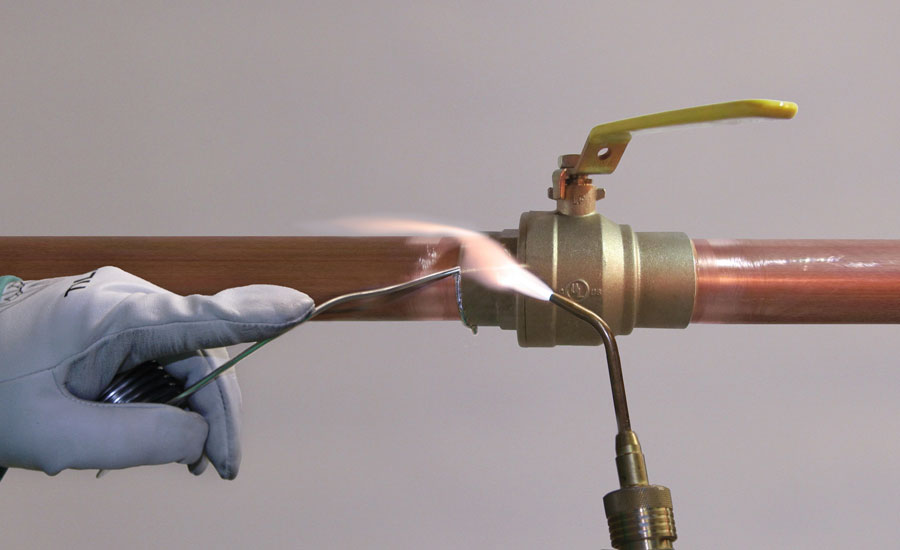

Weld

This type of fittings is used infrequently because it requires special equipment and highly skilled personnel. To connect this way can only be metal pipes, for HDPE brass fittings for welding is not suitable. In addition, the connections are molded - to change the configuration of the pipeline if necessary will not work. Will have to completely dismantle the structure.

The Most popular type of welding with the use of brass fittings - capillary soldering. She is using a burner and additives. Between the parts is left a gap of about 0.5 mm. the Molten additive under the influence of capillary forces "sucked" into the gap and fills it, creating an air-tight monolithic connection.

For the installation of pipelines in areas most commonly used weld. For this purpose, use a special welder that melts the end of the pipe and firmly presses it against the fitting, forming a solid seam. Very important point is the accurate matching of the diameters of the pipe and the fitting then the seam will get high quality.

You Can press details and using hand-held equipment, but this method is less reliable: if the stress is insufficient or at some point will weaken the seam will be defective. This can further lead to accidents, the removal of which the welded tubing requires much more time than in the case of threaded or compression designs.

There are two method of welding of brass fittings for pipe - female and electrofusion. In the first case the process is similar to the butt weld, but it uses a different type of welding machine as welding takes place when entering the pipe ends to each other. If butt connection pipe diameters should be identical, here the outer size of the first part shall be equal to the inner size of the other.

When electrofusion welding between the joined ends of the pipe has a special coupling, which directly and communicates through located in the heating element. Power to the coupler is supplied by the transformer, the ends of the parts to be welded are melted off, and in the process of cooling the compound acquires additional strength.

Buying Tips

When purchasing the fittings should pay attention tosome points that may indicate low quality of the products offered:

- Weight - high-quality brass fitting may not weigh as a feather. Low weight means that the product is made of thin metal and will be short-lived.

- Price is a very low cost suggests that the product is manufactured in China, these fittings can be made from low grade alloy or differ by poor performance.

- Marking - high-quality products, all symbols should be easy to read, doesn't have missing letters or numbers.

- The Quality of coverage - if fitting a chrome-plated or Nickel-plated, you need to carefully inspect the surface - it should be no scratches, chips or scuffs that can eventually lead to corrosion.

Fittings specific product, they cannot buy anywhere. Must be purchased in specialized stores and do not hesitate to ask sellers of quality certificates.

Article in other languages:

AR: https://tostpost.com/ar/business/22829-brass-fittings-the-types-purpose.html

BE: https://tostpost.com/be/b-znes/40242-latunevyya-f-tyng-raznav-dnasc-pryznachenne.html

DE: https://tostpost.com/de/business/39786-messing-beschl-ge-arten-zweck.html

ES: https://tostpost.com/es/centro-de/39515-accesorios-de-lat-n-la-variedad-la-asignaci-n-de.html

HI: https://tostpost.com/hi/business/24455-brass-fittings-the-types-purpose.html

JA: https://tostpost.com/ja/business/22373-brass-fittings-the-types-purpose.html

KK: https://tostpost.com/kk/biznes/40625-zhez-fitingter-t-rler-ta-ayyndau.html

PL: https://tostpost.com/pl/biznes/42495-kszta-tki-mosi-ne-rodzaje-zastosowanie.html

PT: https://tostpost.com/pt/neg-cios/42124-lat-o-a-variedade-a-atribui-o-de.html

TR: https://tostpost.com/tr/business/37189-pirin-par-alar-e-itleri-randevu.html

UK: https://tostpost.com/uk/b-znes/41128-latunn-f-tingi-r-znovidi-priznachennya.html

ZH: https://tostpost.com/zh/business/35690-brass-fittings-the-types-purpose.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

German "Leopard" tank, popular in many countries

the Primary fighting machine of Germany is called "Leopard 2". The tank was established in 1979 and to the current time already has a few modifications. In the process of its development worked out the concept of cannon ...

What distinguishes biological wastewater treatment?

today, according to experts, there is a great variety, and most importantly, effective methods of water purification, among which biological, chemical, and mechanical.In this article we will consider in more detail the issue of bi...

What is the organization? Definition and classification

All of the organization can be divided into groups according to some parameters or similar signs to identify a common methodology of analysis of economic activities, improvement of regulation and control. Classification ...

Types of solar cells and their characteristics

the Batteries on the solar cells are beginning to gain popularity among the population. They are mounted on rooftops, vehicles. Some of them are adapted even for electronics, a wrist watch. At the moment they have become a viable ...

Discount rate as the analysis parameter investment planning

the Conduct of any activity is impossible without the implementation of a thorough financial analysis, which also includes investment planning, business planning for the future ongoing evaluation activities. The analysis of any of...

Every educated person needs to understand what the supply and demand in the market and how these concepts affect the price level. As you know, manufacturers are unable to provide an unlimited number of products and services, as po...

Comments (0)

This article has no comment, be the first!