Now - 16:21:59

Plate-type heat exchanger: working principle. Plate heat exchangers: the device

Heat Exchangers — a simple design of the device, often included in diagrams of different kinds of industrial equipment. They are sometimes used in home cooling systems and air conditioning systems. As can be inferred by the name, these devices are designed to recover the heat from one medium and transfer it to another.

Basic types of heat exchangers

The specialized equipment can be used different types of such devices: lamp, graphite, shell and tube, spiral, etc. However, the most economical, efficient and popular type is the plate heat exchanger. Working principle it is based on a simple heat transfer through the metal. The dimensions of this kind of exchange is small, and the cost is low. To use these devices in the equipment of different purposes.

Design Features

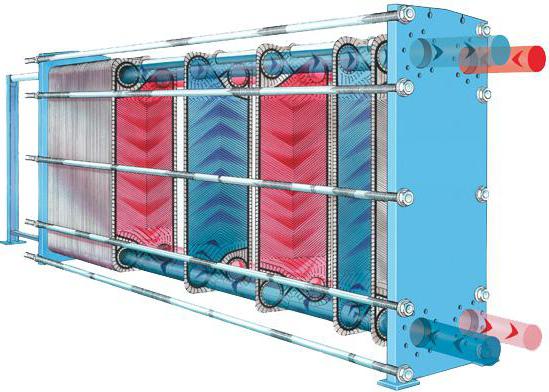

Plate heat exchanger device and principle of operation (diagram presented in the article confirm this) which is actually very simple, consists of the following main elements:

- The fixed Front plate with nozzles. Using the latest in heat exchanger get both working environment.

- Upper and lower guide rods. These elements are required to stiffen the whole structure. The same function performs a back support device.

- Rear movable plate.

- Plates Themselves.

- Sealing gaskets that serve both separators between the plates.

Sometimes the tubes in such heat exchangers are installed not only on the front but on the rear panel. In this case, everything depends on the destination device and a method of incorporating it into the system. During Assembly of the heat exchangers are also used different kind of supplies: fasteners, bolts, rubber bushings, etc.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

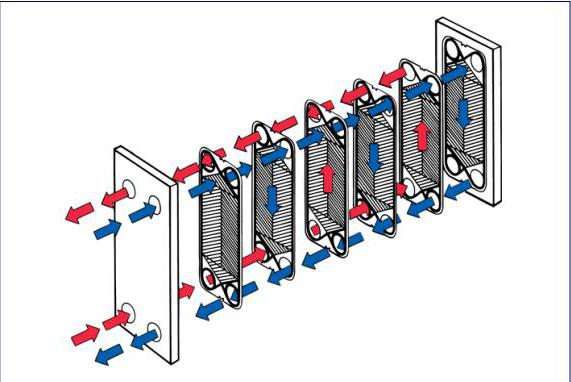

Modern plate heat exchanger: working principle

Functioning device of this type in cross pattern. Sections, alternately filled with heated and cooled environment. The heat exchange between them takes place through the fins. The filling of sections in operation, the device seals the seals of different shapes. The latter can either ignore the environment, or to detain her. As you can see, this is a very simple working principle. Plate heat exchangers are arranged so that the environments within them are moved towards each other. While heating is supplied from above and exits at the lower pipe, and cooled, and Vice versa.

Thus function of all such devices. Working principle a plate heat exchanger for DHW exactly the same as the models designed for air conditioning, refrigeration lubricants, etc. The only difference is passing through the body types of environments. In the model for hot water — it is, accordingly, water in other devices of this type exchange can occur between the fluids, oils, gases, etc.

Specifications

When selecting plate heat exchangers usually pay attention to such indicators as:

- Power;

- Consumption;

- Material and size of plates;

- Packing material;

- Working temperature;

- Allowable size of solid particles in the media;

- Maximum working pressure.

Appliance

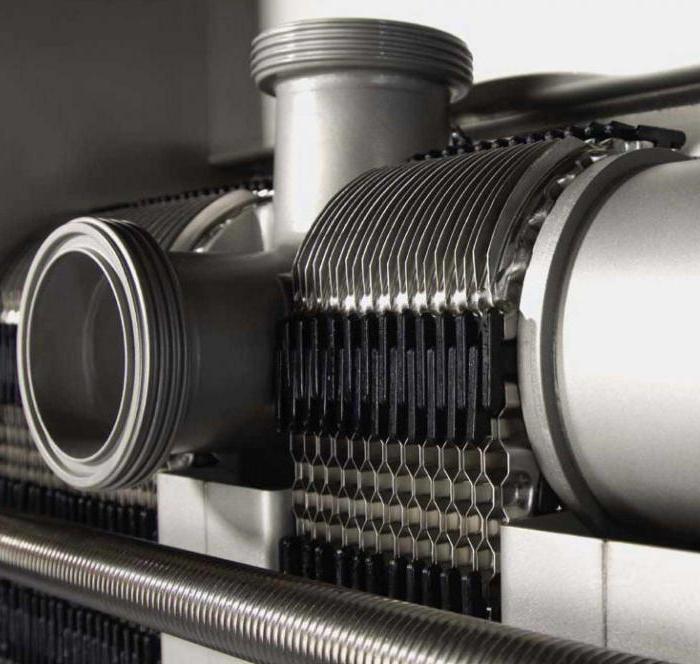

Thus, we have found out, what is a plate heat exchanger working principle. Device plates in this easy to use equipment basic. Each has 2 holes in the environment. In addition, the plates can have relief that facilitate the passage of liquids or gases. Their thickness depends on the destination, size of the device and the pressure in it.

As these elements of the exchanger are constantly in a hostile environment, they must be made of the most resistant material. Most of these plates are made of stainless steel. It is usually used 1.4404/AISI 316L. This steel contains molybdenum, and therefore has high resistance to corrosion damage and effects of chloride.

In that case, if through the heat exchanger are not too aggressive environments, for the manufacture of plates can be used in a conventional grades of stainless steel. Very often also these elements are made of titanium or titanium-palladium. Used in their manufacture, and other materials.

Heat exchanger Gaskets

The quality of these elements depends on the durability and reliability of the heat exchanger. The seals prevent mixing of the media and direct them along a certain trajectory. At the moment, in heat exchangers used in only two kinds of such elements: clip-on and adhesive. For the manufacture of seals normally used are materials based on rubber. This can be, for example, EPDM, PVR, Viton, etc.

Adhesive seals are mounted in special grooves in the epoxy. Folding options are set by means of special fixing elements.

Capacity and consumption

Used plate heat exchanger, the principle of operation of which the construction is convenient, can in various sectors of the economy. And consequently, the power of such devices varies in a rather wide range. To date, different kinds of heating and cooling systems use heat exchangers with a capacity from several hundred kilowatts to tens of megawatts. Depends on this indicator is mainly used in the device plates and their sizes.

To Operate a modern heat exchangers of this type can temperature range (from -30 to 200 O). It is better if cooled and heated environment will be clean enough. However, the special sensitivity to this factor plate heat exchangers are no different. In most models the maximum size of solid particles in the medium is 4 mm.

Pressure and Temperature

In our country the heat exchangers are usually made according to GOST 55118-83. Such devices are in most cases able to withstand pressure up to 1.6 MPa. Temperature work environments in the domestic models may vary from -30 to +180 degrees.

Scope

Plate heat exchanger, which allows to include it in systems of different construction can be used:

- Mechanical production. With the use of such devices are cooled lubricating fluid, hydraulic and gear oil, etc.

- Piston and turbine engines.

- In the power stations.

- Compressors.

- In navigation. On vessels heat exchangers are mainly used for Central cooling.

- In the light industry.

- Mechanical engineering and metal working.

- In systems of heating and air conditioning.

Modern plate heat exchangers, the device and the principle of which was in detail considered by us in the article, thus, it is possible to consider the equipment reliable, efficient and easy to use. Everything else, and there are such models in comparison with other varieties cheap. All this makes their use in different kinds of cooling and heating systems more than appropriate.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Niobium strip: production, properties, application

NB – a chemical element with sequence number 41. It was first discovered in the early nineteenth century, however, its recognition has been postponed for 150 years. Only in 1950 the decision of the International Union of app...

Hospitality is a valuable quality, which is inherent exclusively mannered people. Good manners, specialized education and friendliness of the staff, as well as the high level of service - the constant companions of the Horeca busi...

Cost analysis for production of electricity

Analyze the cost structure of electricity production shows that at the current stage of development of industrial production the trend of reduction of energy intensity dominates over the tendency of growth of power. A significant ...

Growing melons in a greenhouse.

Greenhouse – a wonderful invention of mankind, helps to grow various plants in areas unsuitable to their natural habitat outdoors. But since you want to treat yourself and your loved ones with fresh greens, aromatic herbs, j...

NPO "Lianozovo Electromechanical factory": history, description, address

Scientific-production Association "Lianozovsky Electromechanical plant” is one of the leading Russian industrial enterprises operating in the field of design and manufacture of radar equipment. LEMZ specializiruetsya in...

Methods of decision making in management

the – the greatest of the arts. And although many people think that they know better than everyone and could change the lives of others, and the work of the company to do more effective, in fact, the ability to manage &ndash...

Comments (0)

This article has no comment, be the first!