Now - 21:42:46

Blast furnace - a furnace for smelting iron

For iron smelting in the modern steel industry uses blast furnace. This is a shaft-type furnace, which is a not very complex structure, which, however, looks impressive. To bring the production of cast iron to perfection, mankind had to accumulate centuries of experience.

Partly explains what Domna, old Church Slavonic the root of its name. “Dmit” means to blow.

Ancestors of blast furnaces - stokopani

In the middle ages had to do with different metals. Weapons and tools made of steel, flexible and rigid, and the usual iron went to the utensils. Syrodutny furnace was used to obtain the desired metal with a very long time, for millennia, and they are quite responsive as long as reserves are depleted fusible ores. High temperatures were achieved by increasing the height (so increased thirst), air-pumped and hand-bellows. Over time, however, Europeans had to switch to lower-quality raw materials, which served as a stimulus to progress. The steel stokopani the invention, after which there was the first blast furnace. It was a furnace of the closed type, working in cycles. It had to load ore, coal, then, place the heating chamber (manual effort is not enough, so I used the drive from water wheels), and then had to wait for cooling and removing the metal, separating it from scale and other unsuitable byproducts, called bloom. The main advantage of Shtukaturov was better concentration of thermal energy due to the closure volume throughout the operating cycle due to the reduction of its leakage into the atmosphere.

Iron civilization

The Main problem of medieval metallurgists in the thirteenth century was the refractoriness of iron. When stukiene got cast iron (i.e., iron-alloy with a carbon concentration of 1.7% and above), I was surprised of its low melting point, but this name is not mentioned. The obtained metal to been easier than steel, and especially iron, but the mechanical quality, in terms of the then consumers left much to be desired: too fragile and is not strong enough. However, in just two centuries the attitude of the cast has changed. First, remove it from the oven proved to be simple, it could simply merge in the molten form. Secondly, this metal is found still used, and very varied. And thirdly, it was a raw material for further clean-up of excess carbon, and to obtain from it the steel was much easier than from ore. So, after centuries of experiments, have been found most productive of metallurgical technology, and invented a blast furnace. Bake in the Westphalian city of Siegerland (second half of XV century) could work with a continuous cycle for several years, producing daily over a ton of cast iron. Then it was a lot.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Building blast furnace

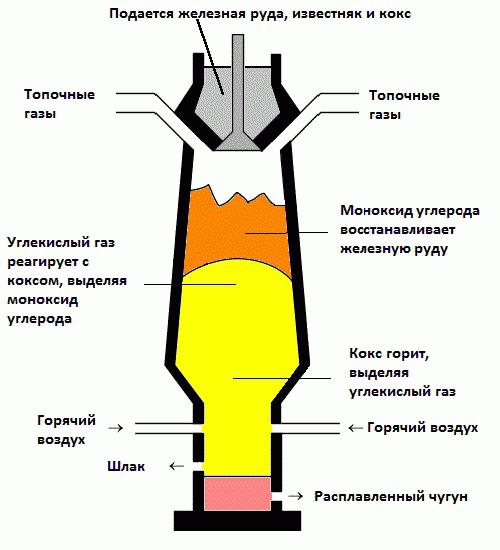

Only after being around this gigantic oven, you can understand how big modern blast furnace. Photo gives an idea of its gigantic size only when they depict a person who looks a little like an ant. However, despite the impressive appearance, the operating principle remains the same, medieval. The design includes five main components. Top of them, the furnace top, for loading of raw material and its uniform distribution inside the furnace. Below it is a part of conical shape, which is heated and restoration process (described later). Third from the top the unit called Respray, there is a melting of iron. Then another conical part, this time narrowing downwards, - the shoulder, which stands out from coke carbon monoxide (reducing gas). And at the bottom – horn, from which is extracted the finished product and waste production.

Process Chemistry

Chemical processes are oxidation and reduction. The first means a compound with oxygen, the second, on the contrary, the rejection of it. The ore is an oxide, and to obtain iron required a reagent capable of “select” the extra atoms. The most important role in this process is coke, in combustion emit a large amount of heat and carbon dioxide, which at high temperatures decomposes to monoxide, reactive and unstable substance. WITH strives to become the dioxide and meeting with the molecules of the ore (Fe2O3), “consuming” they have all the oxygen, leaving only iron. There are, of course, and other substances in raw materials, unnecessary, which form a waste called slag. How it works blast furnace. This, from the point of view of chemistry, is a simple reduction reaction, accompanied by heat consumption.

What is she, a modern blast furnace?

The service Life of blast furnaces is relatively small for buildings of this scale - about a decade. During this time, the structure undergoes large stress, aggravated by thermal heating, and then require major repair or demolition. The production of iron cannot be called harmless, it is associated with emissions of phosphorus, sulphur and other very useful substances. Taken together, these factors encourage many countries to curtail the production of steel or to upgrade it (especially if the industry is a basic and budget). Modern blast furnace is rather simple in its principle, the system, which requires, however, a complex control scheme with many control loops, ensuring the most efficient use of raw materials and energy.

...Article in other languages:

AR: https://tostpost.com/ar/business/9495-blast-furnace---a-furnace-for-smelting-iron.html

BE: https://tostpost.com/be/b-znes/17037-domna---geta-pech-dlya-vypla-k-chygunu.html

DE: https://tostpost.com/de/business/17047-domna-ist-ein-ofen-zum-schmelzen-von-gusseisen.html

ES: https://tostpost.com/es/negocio/17060-domna-es-un-horno-para-la-fundici-n-de-hierro.html

HI: https://tostpost.com/hi/business/9501-blast-furnace---a-furnace-for-smelting-iron.html

JA: https://tostpost.com/ja/business/9501-blast-furnace---a-furnace-for-smelting-iron.html

KK: https://tostpost.com/kk/biznes/17035-domna-pesh-bal-ytu-shoyyn.html

PL: https://tostpost.com/pl/biznes/17016-domna---piec-do-wytopu-eliwa.html

PT: https://tostpost.com/pt/neg-cios/17015-domna-um-forno-de-fundi-o-de-ferro-fundido.html

TR: https://tostpost.com/tr/business/17044-domna---f-r-n-eritme-demir.html

UK: https://tostpost.com/uk/b-znes/17033-domna---ce-p-ch-dlya-viplavki-chavunu.html

ZH: https://tostpost.com/zh/business/10366-blast-furnace---a-furnace-for-smelting-iron.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

leeks,the cultivation of which is on a par with onions and rightfully competes with him in taste and vitamin properties. So, for example leek contains more vitamin C, carotene and potassium. And to raise him much easier because he...

Uncertainty and risk in decision-making

the Management of the enterprise, as well as, for example, state tasks of socio-economic nature, can be carried out taking into account the relevant uncertainties and risks. What is their specificity? How can they be calculated?wh...

How to choose the right fastener?

Almost everyone who was holding a screwdriver or a hammer, knows what the fastener. This definition fits any metal object that allows to interconnect two parts. In this fairly large list of available bolts, screws, bolts, anchors,...

management Styles – is not that other, as the manner of management and methods which are used by the head, interacting with subordinates and organizing the workflow. You see, the efficiency often depends on how the authoriti...

Saint Petersburg Russian and foreign guests called one of the most beautiful cities in the world. Architects and designers have to be very careful in erecting his new building did not violate the integrity and style of urban desig...

quality Control – an obligatory component of any production process, which aims to detect defects or defects of finished products and verification of process of its manufacturing. quality control Methods applied at all stage...

Comments (0)

This article has no comment, be the first!