Industrial boilers: description, types, functions. Examination of industrial boilers

Equipment for the production of thermal energy for several centuries used. During this time of construction aggregates has varied, allowing the owners to obtain higher performance. In our time, this segment of industrial machinery represented by many variants, which differ in size, performance, type of fuel used and other parameters. The new generation industrial boilers are equipped with automatic control systems functional relay and control panels. Such additions enhance the ergonomics and reliability of the units.

Features industrial boilers

Unlike the domestic models of industrial equipment is calculated on maintenance of the productive facilities that require high performance heat output. To perform this task, and guided by boiler manufacturers. This is usually a massive structure that represents a complex multi-component system of mechanisms and communications. Classic units are used devices that enable the production of steam or hot water. In a traditional set of elements, which include industrial boilers, includes combustion chamber, exhaust fans, water treatment and nutritional installation, and protective devices. The increasing performance requirements, the list is expanded, supplemented with new components working infrastructure.

What are the functions of industrial boilers?

A Traditional unit of this type serves to generate steam which is further used as a medium to drive the motors. In particular, such tasks are performed at the power units, locomotives and power turbines. For modern industry, the production of vapor is less important, and in the foreground a function of supply of heat energy. A kind of technical heat required for the needs of different industries, among which textiles and agriculture. In the public service are also used in industrial heating boilers, which provide hot water generation. Depending on the operating conditions and requirements equipment is selected the boiler with certain properties and capabilities. For understanding the differences between the variations of such units should be familiar with their classification.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Classification equipment

There are two approaches to division of industrial boilers – based on the types of coolant used fuel. With regard to the first characteristic, the quality of the work environment most often is water, although steam is also does not lose its relevance. Less mercury is used, various adhesives and other compounds, which mainly perform the functions of technological support targets. Structural features possessed by industrial boilers, the brighter apparent in the classification of units by kind of fuel used. In this case, the allocated equipment working on solid-state resources, gas mixtures, electricity, etc.

Steam units

The Representatives of this category, as the name implies, is designed to generate steam. Units industrial type produced for the purposes of technical support. In particular, such equipment is used in sawmills. Steam effect allows to maintain optimum humidity in the drying chambers. In medicine, industrial steam boilers are used for sterilization of work clothes and working equipment, and agriculture uses them in the manufacture of fertilizers and feed. It is important to separate saturated and superheated steam. In the above-listed branches is just a rich coolant. Superheated steam, in turn, is used in special turbines of power plants. Therefore, the boilers of this type are also referred to as energy. Often the units that produce superheated steam, used in a single complex with the generators of the saturated thermal environments. This nuance can be attributed to the power plant to industrial boilers.

Hot Water boilers

This is one of the largest categories of industrial boilers. Hot water models are used for training environments under high pressure. Boiling water equipment is not permitted, and the pressure at all points do not exceed the threshold for the creation of conditions of saturation of the coolant. Water heating installation is mainly used with the purpose of heating. In particular, they are applied in municipal services to service the district heating plants. Common and industrial hot water boilers, is designed to provide the functions of thermal power plants. This so-called peak units, whose functions are limited to the provision of additional heating. The boilers of this type are also divided into water - and gas-pipe model. Water tube installation have a display surface heating, consisting of heating elements with the contents of the liquid coolant.The heat transfer process is realized by heating the tubes with the combustion products. Gas-pipe models are also on the working surface of the heat pipes contain a small size, but the quality of the coolant used directly in a combustion products.

Gas boilers

Engineering and utilities equipment operating on gas fuel, is traditionally considered the most economical in terms of operating costs. In addition, a full cycle of processing of products of combustion is reflected in the minimum emission of harmful particles into the atmosphere. Also, the advantages of such boilers include the high heating rate, which allows us to serve a large area without delay. Not yet across the country, but overall the trend is stable gas supply, therefore, increases the relevance of such equipment. But industrial gas boilers have serious disadvantages. Chief among them is security. Still, the exploitation of gas in the form of a fuel component and partly of the coolant theoretically pose a threat of explosion. Understanding this nuance, manufacturers seek to minimize these risks. For such purposes the improved automatic control system for boilers and their shell is made of high-strength modern materials.

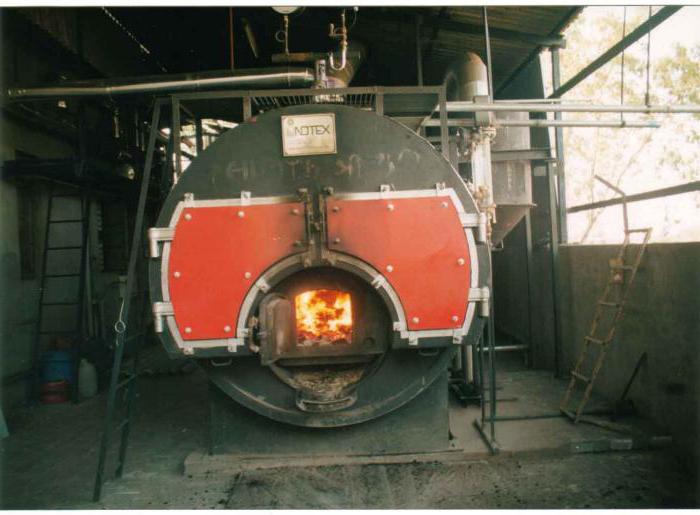

Solid equipment

These boilers as a fuel resource use wood, peat, pellets, coal, etc. the unit Design provides for a ash pan, which as the combustion fuel sent processed products. Of the need for constant maintenance of equipment cleaning and cleaning zolnikov and loading of solid components is one of the main disadvantages of such models. However, it is the industrial units in this sense is not so problematic because are equipped with automated mechanisms for performing tasks contents. In addition, industrial solid fuel boilers are self-contained. While most of the analogues suggest a connection to the main utilities, this unit is fully independent and requires only the timely delivery of fuel. Duration of work with the release of heat energy when it is small, which limits the scope of application of solid fuel boiler.

Universal boilers

The Concept of universal equipment today is more fully disclosed in the example of solid and biocatal. The relevance of models, capable of operating on multiple fuel types, due to the desire of manufacturers to promote biofuels. Not all consumers are willing to switch to pellets, so the developers almost as options provide the classic industrial boilers cameras to work with the same pellets. The result is a hybrid design, featuring flexibility and financial efficiency.

Industrial boilers

It has been noted that gas boilers are considered the most dangerous equipment in its class, but involves certain risks and operation units of other types. To prevent undesirable situations in the enterprises conducted a special examination, the purpose of which is to check the condition of equipment and quality standards maintenance. The examination of industrial safety of boilers in the following cases:

- After reaching the assigned resource units.

- After recovering from the effects of the accident.

- After repair operations or upgrade equipment.

Also the need for the examination can be caused by a doubt as to the quality of execution of the rules of operation. Especially if was found in violation of instructions, or defects in the boiler.

Manufacturers

Segment wide enough for almost any task you can find a suitable option. For example, under the brand name Byworth produces reliable and durable water heating boilers with capacity of 1000–5000 kW. In the line presented a model for solid fuel, and diesel. If high industrial safety of boilers, it makes sense to refer to the product De Dietrich Thermique. The company produces a family of reliable operation combined units with cast iron housings that can be used in maintenance and communal services and industrial enterprises. For smaller tasks it is necessary to consider the Turkish model Erensan boilers. Units suitable for operation on gas fuel and liquid supply.

Conclusion

In addition to the working principle and structural performance, boiler equipment and different performance characteristics. The capacity of the furnace, the generated power and the amount of thermal energy – not less important parameters describing the operation of the unit. In recent increases, and the significance of issues of security of such equipment. Regular examination of industrial boilers allows to identify faulty equipment, and deviation from the standards of its service. However, the producers themselves in different directions can enhance the security of its products. It is enough to note the development of systems for monitoring andboiler control, additional strengthening of buildings and increase maintenance demands.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Independent examination of the car repair from the center for judicial expertise and research, Saint

the Center for judicial expertise and research, "the Saint" offers his professional services to all in need. Our specialists arrive on the scene and impartially evaluate the property. If you surrendered the vehicle ...

How to earn 100,000 rubles per month? Profitable business, the real earnings

If someone convinces you that knows how to make 100000 in a month, moreover, says he already has the income with no investing a dime and does almost nothing – do not trust this man. Most likely, you are dealing with a scamme...

Ultrasonic testing of welded joints, methods of control

there is almost No industry, which would not have carried out welding work. The vast majority of structures are assembled and are joined together with welds. Of course, the quality of carrying out such work in the future depends n...

Corporate standard: rules and implementation stages

have You ever thought about what makes a successful, dynamically developing company from the hundreds of small shops, sales of which over the years remain at a low level? Every prosperous organization has a corporate standard. He ...

Harvesters Rostselmash: photos, reviews, model range

the Company "Rostselmash" produces a variety of agricultural machines. Harvesters of this brand are doing a good job cleaning the grain. It is also worth noting that by design, they are very different. Threshers are not available ...

Mentoring as a method of staff training. Assistance to young professionals in the new job

Mentoring in the enterprise is recognized as one of the best on the efficiency and effectiveness of the methods that are used for training new employees.a Peculiarity of the current situation in the business world can be called a ...

Comments (0)

This article has no comment, be the first!