Now - 22:45:11

Damascus steel – the history and manufacture of

The Manufacture of Damascus steel is a very laborious and lengthy process that requires extensive experience and knowledge of a blacksmith. In the technology of providing high quality products by optimizing the alternation of different layer settings. As a softening of the substrate between the layers containing a high percentage of carbon, used low carbon steel. Because of this combination of Damascus steel gets a special sharpness and hardness.

The History

Blades created from Damascus steel, are never made in large quantity. They always exist in a single copy and have a unique structure, which has no comparison.  Damascus steel today - is, above all, exceptional quality and inventiveness of the master. The name of this alloy is derived from the city Damascus, located in Syria, which represented the largest centre of various crafts in the middle East. However, there is a view about the invention of this alloy in India. Europeans first saw the products of this steel in Damascus, since the alloy is called "Damascus steel", which is used currently. The technological process was very complex, and the secret of its manufacture is very carefully guarded. This explains the very high cost of weapons, the Damascus is made of alloy. The nature of the product determines the master who made it. Each blacksmith has their own characteristic style and “handwriting” with the secrets of heat treatment.

Damascus steel today - is, above all, exceptional quality and inventiveness of the master. The name of this alloy is derived from the city Damascus, located in Syria, which represented the largest centre of various crafts in the middle East. However, there is a view about the invention of this alloy in India. Europeans first saw the products of this steel in Damascus, since the alloy is called "Damascus steel", which is used currently. The technological process was very complex, and the secret of its manufacture is very carefully guarded. This explains the very high cost of weapons, the Damascus is made of alloy. The nature of the product determines the master who made it. Each blacksmith has their own characteristic style and “handwriting” with the secrets of heat treatment.

Process creation

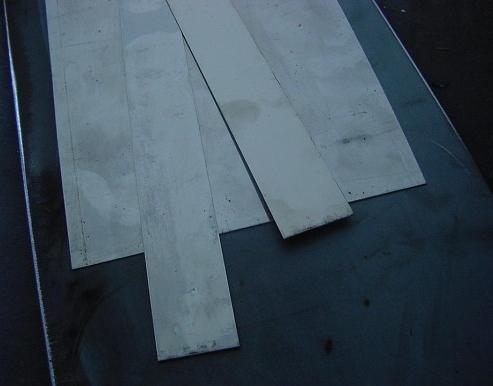

The Damascus steel, the production of which is the right choice of steel grades, the knowledge of their chemical composition, high-quality treatment is characterized by an unusual pattern of the blade.  To the group of the Damascus steels are refined steel and welding Damascus. The secret is in the careful combination of plates from blanks with different carbon content. Blanks are joined together by welding and forging. The process can be repeated many times. The result is an alloy with a combination of benefits of iron and high carbon steel. Stainless steel, which is made of a plate, is heated in the forge, after which the workpiece is intensively prokovyvayutsya in the forge.

To the group of the Damascus steels are refined steel and welding Damascus. The secret is in the careful combination of plates from blanks with different carbon content. Blanks are joined together by welding and forging. The process can be repeated many times. The result is an alloy with a combination of benefits of iron and high carbon steel. Stainless steel, which is made of a plate, is heated in the forge, after which the workpiece is intensively prokovyvayutsya in the forge. Thus, a higher strength alloy. Further, the workpiece rusk in a plate, cut and again placed in the furnace. The process can be repeated several dozen times. Some of the blanks for the blades can have up to 500 layers of steel. To obtain a characteristic pattern on the blade, the workpiece is etched.

Thus, a higher strength alloy. Further, the workpiece rusk in a plate, cut and again placed in the furnace. The process can be repeated several dozen times. Some of the blanks for the blades can have up to 500 layers of steel. To obtain a characteristic pattern on the blade, the workpiece is etched.

Mosaic Damascus

In recent years, mosaic Damascus has a special popularity. Damascus steel made in this way differs from the blacksmith because the design pattern is carried out in advance through the placement profile and the contrast of metal within the billet. After the parts are joined together by forging, the workpiece is created inside a composite package. Industrial manufacturing of Damascus steel uses the same principles as the author's Damascus.

Article in other languages:

AR: https://tostpost.com/ar/business/22858-damascus-steel-the-history-and-manufacture-of.html

BE: https://tostpost.com/be/b-znes/37071-damaskaya-stal-g-storyya-vyrab.html

DE: https://tostpost.com/de/business/37177-damaskus-stahl-geschichte-und-herstellung.html

ES: https://tostpost.com/es/centro-de/39527-el-acero-damasquino-la-historia-y-la-fabricaci-n-de.html

HI: https://tostpost.com/hi/business/20686-damascus-steel-the-history-and-manufacture-of.html

JA: https://tostpost.com/ja/business/22391-damascus-steel-the-history-and-manufacture-of.html

KK: https://tostpost.com/kk/biznes/36802-damask-bolat-aza-stan-tarihy-zh-ne-dayyndau.html

PL: https://tostpost.com/pl/biznes/35788-adamaszek-stal-historia-i-produkcja.html

PT: https://tostpost.com/pt/neg-cios/36013-damasskaya-a-o-hist-ria-e-fabricante.html

TR: https://tostpost.com/tr/business/37210-am-elik-hikaye-ve-imalat.html

UK: https://tostpost.com/uk/b-znes/36682-damas-ka-stal-stor-ya-ta-vigotovlennya.html

ZH: https://tostpost.com/zh/business/18102-damascus-steel-the-history-and-manufacture-of.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

The largest aircraft in the world - comfort and efficiency

the Competitive spirit will never leave humanity. In every sphere of life people try to surpass previous achievements, to become the first to win the pedestal. No exception and aircraft. The title of "largest airplane in the world...

Open-hearth furnace and its importance in the production of steel

the Main melting unit in steel production open-hearth furnace is. It is designed for smelting of steel with specified chemical composition and specific physical and mechanical characteristics. Open-hearth furnace, which has surviv...

Management of investment projects – real opportunity to reform the country's economy.

Management of investment projects and effective use of all concepts of project management in the real sector of the economy – this is a promising opportunity to reform all sectors of the domestic economy. Currently, methods ...

An-148 – a new "workhorse" medium aviaregistr

Aircraft KB them. Antonov has its own unique style. Since the aircraft An-8, An-12, and, of course, An-24, it manifests itself in a rational layout, high-wing with a high degree of mechanization and the chassis, allowing to land o...

The utilization rate of production equipment is the guarantee of success

Every company has a warehouse – technically complex structure, the purpose of which – reception, distribution and storage of various products. The warehouse is a key part of the enterprise. Competent organization of wa...

Boeing 757-300 – medium and long - haul passenger airliner made its first flight on 2 September 1996. After certification, the aircraft entered service in the airline Condor in March 1999. The aircraft is used on regular fli...

Comments (0)

This article has no comment, be the first!