Now - 22:57:58

Vogele paver. Specifications, performance

The history of the company building lasts for more than 150 years. The company has overcome many obstacles until he found his true calling. Until 1926 they were manufacturing equipment for the railway industry. After some time has passed to release the pavers.

Stacker belongs to the category of complex machinery and requires high qualification of engineers and developers. Machines perform the typical tasks associated with laying asphalt mixture and its alignment. One unit can replace a whole range of machinery. Everything you need stacker, timely delivery of working material.

Building - leading road construction machines

After the first successful sample of the company's specialists thought about improving your skills. In 1950, a model was developed with the hopper for ready mix asphalt, in the same year the car came out of the factory building. The paver was a kind of breakthrough in road construction at that time.

In the modern market building occupies the first place among the techniques of this class. The company is no longer engaged, in addition to creating and improving machines for laying asphalt, as well as additional equipment for them. The advent of mobile feeders, where the mixture is continuously fed, due to the need of process automation. This helped to speed up the laying of the roadway at no additional cost. The first, who used this type of system was considered by the company.

There's Not one company that could compete with the building. Paver designed by engineers, paired with mobile feeder forms a complex, which can work autonomously.

Recommended

How does the rear bushing front arm and how many it serves?

The Rear bushing front arm – one of the constituent elements of the vehicle chassis. He refers to the guide elements of the suspension together with the levers endures tremendous stress with wheels. However, with this this item, there are many ...

Oil consumption in the engine. Six reasons

It is Hardly possible to find a motorist who would not be worried about the increased oil consumption. It is especially annoying when it happens with another new motor. Here are the most common causes that result in the consumption of oil in the engi...

The exhaust System is designed to remove combustion products from the engine and output them to the environment. It also must be ensured a reduction in noise pollution to acceptable limits. Like any other complex devices, this system consists of seve...

Vogele 1603-1 Super

Under model number 1603-1, the company issued an aggregate of universal use. It is suitable for laying asphalt pavement on streets, sidewalks, houses adjoining areas and on highways and multilane highways.

Working equipment can be supplied in several versions. Typically the most popular among road-building enterprises is considered a model with a pressing plate equipped with electric heating and vibrating device the log type for compacting. Additionally, it is possible to install special bars to improve the seal. Along with a plate customer supplied a separate set of size expanders to 6.5 meters. Model 1603-1 allows for the broadening of up to 8 meters. All attachments can be purchased separately from the official building representatives. Paver equipped with a hopper with a capacity of about 13 tons of ready mix. By means of hydraulic cylinders fold side, thereby providing a full flow of material.

Vogele Super 1800-2

Tracked paver 1800-2 is used to hold larger work than the version of the 1600-2. There are possible applications in small areas, as well as the construction of bike lanes. Thanks to the crawler undercarriage equipment machine has the best stability among the entire line Vogele. The pavers are easy to maintain and operate, and is famous for its reliability and efficiency with high performance. It can even be used as a standalone unit without additional workers.

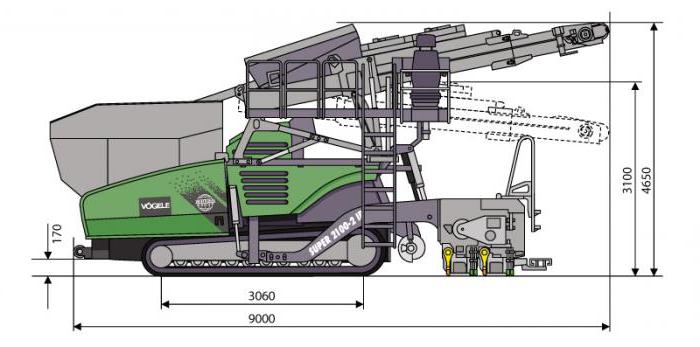

The Maximum width of the stacking surface can reach 9 meters. The thickness of the layer varies from 3 to 30 cm machine Width in transport position - 2.55 m, because of this it may be transported with the trailer without any additional permits that are issued for oversized cargo.

Vogele Super 1900-2

Model super 1900-2 belongs to the class of heavy equipment. This paver Vogele whose specifications exceed the parameters of similar machines of competitors, he has no equal when laying the roadway. By means of a hydraulic actuator extendible plate for alignment of the coating, which can form a strip of 6 meters in just one pass. If you use siritelny devices this figure could rise to 8.5 m. Optionally can be supplied three types of plates with working dimensions 8,5; 9,0 and 10 meters respectively. Rigidity is ensured by the system of the guide tubular section.

Administration

The Main task of electronic systems - creating the design profile of the roadway in compliance with all technology requirements. In 1900-2 used two types of control systems: analog and digital.

First you need to define the reference surface using coperni string that was previously prepared by the team of surveyors. Special probe, gliding over the top, reports to the controller signals about potential deviations. Depending on the received data changes the trajectory for moving the paver Vogele. Characteristics of the sensors may vary depending on the result, which is desirable to obtain.

Digital system uses ultrasonic and laser sensors that measure the height of the point. Parameters pre-loaded intothe machine's control unit. All data is pre-coordinated with chief engineer and team of surveyors. This is necessary in order to reduce the latter's work, as well as to improve the accuracy of the project.

Transportation and distribution

Hopper Capacity is 14 tonnes, a special damper to perform maintenance of the machine. Repair of paver Vogele can be performed directly on the construction site. In this case remove a node and change it with new one. This method of repair saves time, thus reducing the machine downtime.

To prevent mechanical damage to the tank is shock-absorbing shaft, which rests on the side of the truck while the implementation of discharge.

Screw screws required for uniform distribution of the mixture, allow replacement of working blades and set at a height with respect to the supports screw chamber.

Advantages and disadvantages

Machine line Super is presented in 13 frameworks. The unit is capable of forming a strip with a width from 1.8 to 16 m, the performance of the paver Vogele varies from 200 to 1500 t/h.

The Technique can simultaneously carry out the paving, and also to distribute the asphalt concrete mix across the width of the future road, after which it is compacted.

The Main disadvantage of working equipment Vogele is a very high cost units. Repair one machine costs several times more than the same type of work carried out on domestic machines.

The Cost of building

In the market of road-building equipment special demand machine building. To purchase a paver can be quite a variety of prices, it all depends on the technical condition and the degree of developments of equipment. The minimum price on the secondary market for unit 2006 may be equal to 5.5 million rubles.

If we are talking about new equipment, for equipment 2013 release, asking for 19 million. Completely new machine will cost more than 20 million rubles.

A road enterprises do not have sufficient funds to purchase the paver, take it out. On average, it costs 3 750 rubles per one working hour, or 30 thousand per shift. Despite such a high cost, machines are popular. In return, the company receives a reliable technique with very high performance.

Article in other languages:

AR: https://tostpost.com/ar/cars/20376-vogele.html

DE: https://tostpost.com/de/autos/35886-vogele---fertiger-technische-daten-leistung.html

ES: https://tostpost.com/es/coches/36012-vogele---extendedora-especificaciones-de-rendimiento.html

HI: https://tostpost.com/hi/cars/19775-vogele.html

JA: https://tostpost.com/ja/cars/20040-vogele-paver.html

PL: https://tostpost.com/pl/samochody/33599-vogele---brukarz-dane-techniczne-wydajno.html

PT: https://tostpost.com/pt/carros/33914-vogele---paver-especifica-es-de-desempenho.html

TR: https://tostpost.com/tr/arabalar/34907-vogele---fayans-ustas-teknik-zellikleri-performans.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

"IZH 350 Planeta Sport" – frisky Soviet bike

it is believed that of the entire line of Soviet motorcycles "IZH" truly sporty just one. It is easy to guess that it was "IZH 350 Planeta Sport".History motorcycleIn 1973 the factory "Izhmash" was made a real breakthrough: the li...

Car Hino 500: review, features, description and reviews

the Main task of machine-building enterprise is to create the most reliable car that will be able to perform all the tasks. TOYOTA proved itself on the world market as a company producing reliable cars. The leadership made the dec...

Snag lambda probe with their hands: drawing

From the article, you will learn how is made snag lambda probe with their hands and whether or not to install it on your car. This burns the air-fuel mixture in the engine depends on its efficiency. It is very important to choose ...

Model KAMAZ: description, features, photos

Kama automobile plant produces cars and engines, which are dispersed throughout the former Soviet Union. The first serial production began in 1976. Now KAMAZ produces various tractors, buses, mini-power, elements to them, etc. the...

The description of the car Datsun on-Do: owner reviews, photos

the Company “Datsun", located in Japan, belongs to the firm “Nissan”. Recently first got the opportunity to produce their own cars which would be affordable to people with average incomes. The car Datsun On-...

Cars "KAMAZ": description, features, models

the Russian Federation perfectly fulfills the role of transport in the country. She has established a large amount of traffic, and in the most unexpected directions. Parked in the Park you can find over a dozen trucks that are cap...

Comments (0)

This article has no comment, be the first!