Antifreeze additive in concrete: specifications

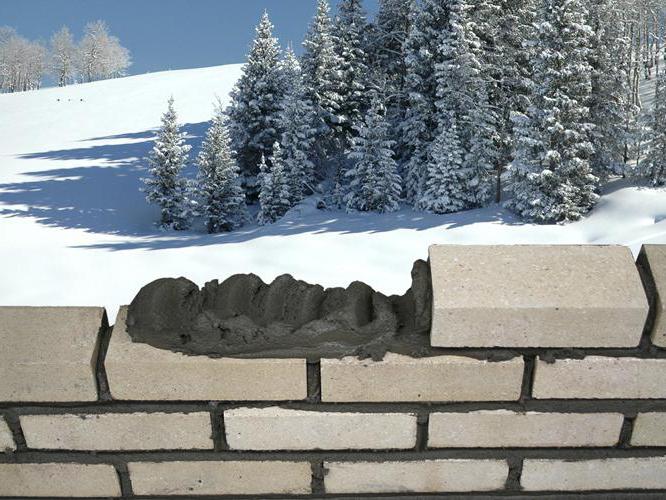

Antifreeze additive in concrete – is a dry mixture or solution of chemical substances, which are characterized by a fairly long shelf life. The main purpose of such additives is the provision of concreting in the winter time.

The New complex antifreeze additives, in addition to the adjustment processes curing of concrete, regulate a number of its rheological properties. As a result of lower temperatures decrease the setting time, accelerate the process of hardening of cement stone, and his brand strength is increased by 2 class.

Classification

Antifreeze additives in the mortar (concrete) the chemical basis can be divided into three main groups:

- Antifreeze.

- Sulfate.

- Antifreeze winter Supplement-boosters.

Let's Consider them in more detail.

Antifreeze

This antifreeze additive in concrete reduces the freezing point of the fluid speeds up or slows down weakly grasp the solution. The antifreeze does not alter the rate of formation of the structures.

Sulfates

Sulfate of iron, aluminum or other metals is antifreeze component, when added, provides the rapid formation of a dense solution. On the strength also has a positive effect active release of heat, which is accompanied by the interaction of concrete with hydration products. This Supplement cannot be used to lower the freezing point, as it is fully associated with poorly soluble compounds.

Winter Antifreeze additives-accelerators

Antifreeze additives in the mortar (concrete) of this type enhance the degree of solubility of silicate components of cement, the result is a double or a basic salt with the hydration products. Most of them at the same time reduce the freezing point.

Recommended

The most effective methods of seed germination

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I...

Retro-reflective paint. The scope of

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic...

How to make icon with your own hands - options izgotovleniya (simple and complex)

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make...

Varieties

- The Potash – this is a strong antifreeze additive in concrete to speed hardening process. With the aim of preventing reduction of the strength of potash is recommended to combine with sulfite-yeast mash, sodium tetraborate, or other retarders. The concentration in the mixture should not exceed 30 %.

- Nitrite of sodium – flammable toxic antifreeze additive in concrete. In the case of a joint application with lignosulfonate possible formation of toxic gases. Dosage must be determined empirically and can be in the range of 0.1-0.42 l/kg cement when the ambient temperature from 0 to -25 ºC.

- Sodium Formate is an antifreeze accelerator. Is used to improve plasticizing, water reducing properties. Recommended to use together with lignosulfonates naphthalene. This antifreeze additive in concrete consumption by weight of the cement on average is 2-6 %.

To organize a concrete work in the winter time, in addition to the above, you can choose antifreeze additive based on sodium formate alcohol, urea, ammonia water or calcium chloride.

Advantages

- Plastifiziert and stabilizes the finished cement mixture.

- Allows you to perform concrete works in winter time.

- Helps to increase the durability of the mixture in the process of maintenance.

- Improves the final frost of the solution.

- Reduces shrinkage deformation.

- Reduces the release of water and the process of splitting.

- Reduces the cost of the installation.

- Eliminates corrosion of internal reinforcing mesh.

The Use of antifreeze additives in concrete will generally lead to significant savings.

Disadvantages

- Some components of the additive are considered poisonous.

- To reliably ensure the strength characteristics increases the consumption of cement.

- Sometimes falls regulated power grade of concrete.

Recommended use

Antifreeze additive is introduced into the concrete along with water, preferably with the last third of the liquid. It is undesirable to introduce the tool in a dry mixture. After the additive was introduced into the solution, need to wait a certain time to ensure uniform distribution.

It is Very important to adhere to the regulations for construction works in winter time:

- During a snowfall it is necessary to perform a special cover.

- The recommended solution temperature at the outlet of the mixer: from +15 ºC to 25 ºC.

- To prepare the mixture, it is desirable to bring the heated water.

- Heated aggregates should be performed immediately prior to use.

To get solution with required strength characteristics, it is recommended to comply with the requirements for caring for concrete in winter in accordance with SNIP 3.03.01. It is desirable to perform activities to achieve strength of at least 20% of the project by the time the solution was cooled to the temperatures which were calculateddosage.

Antifreeze additive in concrete: specifications

| Color | Grey |

| Operating time | At least 3 hours |

| Bulk density | 1300-1400 kg/m3 |

| Aggregate Size | Not more than 0.3 mm |

| Temperature | +5 ºC to 30 ºC |

| Density compression at 28 days of age | Not less than 10 MPa |

| Adhesive strength | Not less than 0.5 MPa |

| The optimal layer thickness | 2-4 mm |

| Expense | 26-37 kg/m3 masonry |

| Mark frost | F 50 |

Dosage

Dosage

The Dosage of additives should be selected for each specific case by testing in production and laboratory conditions. It depends on the following:

- Terms of care for the concrete.

- The temperature of the solution at the outlet of the mixer of the concrete.

- Ambient Temperature.

- Physical and chemical-mineralogical composition of the solution and the speed of curing.

- Grade strength of cement.

During prolonged storage or use of large amount of additives is recommended to periodically homogenize the solution by stirring or bubbling with compressed air. Dosing should be performed with an accuracy of ±2 %.

| The temperature of the hardening solution | Consumption of antifreeze additives for warm solution in terms of dry consistency | Consumption of antifreeze additives to the cold solution in terms of dry consistency |

| -5 ºC | 0,8-1 % by weight of solution | 1-1,2 % by weight of solution |

| -5 ºC to -10 ºC | 1-1,2 % by weight of solution | Of 1.2-1.4 % by weight of solution |

| -10 ºC to -15 ºC | 1.2 to 1.5 % by weight of solution | 1,4-1,8 % by weight of solution |

| -15 ºC to -20 ºC | 1.5% to 1.8% by weight of solution | 1,8-2,5 % by weight of solution |

| -20 ºC to -25 ºC | 1,8-2,2 % by weight of solution | 2,5-3,5 % by weight of solution |

Antifreeze additive in concrete with your hands

It is Worth to note that the preferred option would be to purchase a ready-made additive in concrete solution in any specialty store. They are not so expensive, have small consumption and provide in the winter, a significant improvement in the properties of the solution with minimal negative effects.

With a small scope of work and the temperature is not less than 10 ºC this method will be optimal.

However, it happens that the antifreeze additive in concrete, with his own hands made, – this is the only option. In this situation it is necessary to pay attention to chlorides (salt). Chloride salts can significantly reduce the freezing point of the solution to shorten the setting time and reduce the consumption of cement. But such antifreeze additive in concrete (specialists confirm this) can only be applied to unreinforced structures.

Precautions

When working with a substance of this type is recommended to use protective gloves.

After contact With exposed skin must be washed off with soap and water. Not getting antifreeze additive in the eye. In such a case should be immediately washed off a large amount of water and seek medical advice.

The additive Utilized in accordance with local regulations, is strictly prohibited to pour into drains, surface waters and soil.

Article in other languages:

TR: https://tostpost.com/tr/domashniy-uyut/14227-protivomoroznaya-katk-beton-zellikler.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Why not bloom clematis? What to do, what to feed clematis?

Clematis is a culture with abundant flowering, which is used for vertical landscaping. But this is not always the plant pleasing lush flowering. It happens that the plant does not form buds. Why not bloom clematis what to do, what...

Flour soy is a valuable food product, which is made of meal or seed. In comparison with other types of flour products different high content of mineral substances and protein. Manufacturer of soy flour has some differences from th...

Parapet cap. What you need to know about them

Parapet caps play a very important role in architecture. They not only protect the support structure from the negative effects of heavy rainfall and other natural phenomena, but complete the aesthetic appearance of the structure. ...

Gates, hinged metal: types, photo, manufacture and installation

Automatic metal swing gate is very easy to use – at the site or in the garage is the most secure way to move in. And you do not even have to leave the cabin of the car – to open the entrance you can use a simple remote...

How to calculate the volume of concrete for pouring the Foundation

the Strength and durability of any structure depends on the quality of the Foundation. As in any business to achieve success, you cannot ignore the preparatory stage. The correctness of calculations not only saves time, nerves and...

Beam cucumber Mels F1: reviews, a description of the variety characteristics and cultivation

a Great achievement breeders is the occurrence in nature of cucumbers beam with multiple ovaries on the same plant, which allows to collect a high yield. One of the hybrids is cucumber Mels F1 reviews, where experts and gardeners ...

Comments (0)

This article has no comment, be the first!