Drill pen on wood: size

The Attention of the consumer a wide range of different fixtures used for drilling holes. To work with wood meant the pen drill.

These items are used by both carpenters and professional builders and home craftsmen. Information about the design features, technical characteristics and dimensions of the pen drill bits for tree contains in this article.

Introduction

The Pen bit is a special cutting tool used for drilling various holes in the wood. They can work with both natural wood and wood chip boards and MDF products.

The Wizard can also use such an expensive tool like disc cutter. However, judging by customer feedback, such an application is not sufficiently justified. Better to buy a drill pen on wood. Compared to the disc cutter this tool is much cheaper, in addition, it is no less effective. They can work using the electric drill and standard screwdriver.

Purpose

Pen drills are used to create the following holes:

- The Deaf. They do not have access from the back side of the product. With blind holes and mounted the hinges when installing interior doors and small doors for furniture designs.

- End-to-end. They have the equipment threaded joints: bolts and studs. By using through-holes of the wizard, install door handles and locks.

Device tool

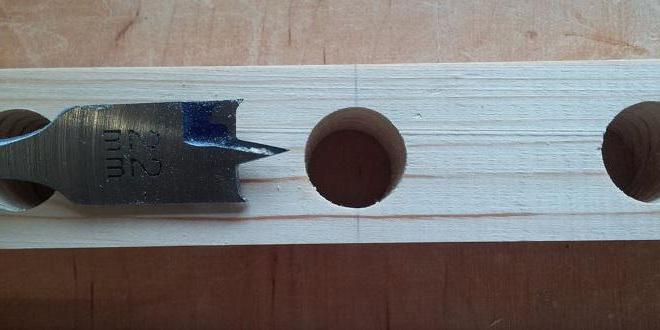

The Pen drill has a simple design. The tool consists of two parts:

Recommended

The most effective methods of seed germination

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I...

Retro-reflective paint. The scope of

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic...

How to make icon with your own hands - options izgotovleniya (simple and complex)

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make...

- Working. Is a flat blade equipped with in the center a hard protrusion. In the process of drilling it performs the alignment. The working part is equipped with two cutting blades, which are arranged on either side of the ledge. Sharpened cutting edge extends from the tip of the protrusion to the edge of the working part of the drill. Tool provides right - or left-hand bevel sharpening. These accessories perform the drill in one direction. For this cutter provides grinding angle in 75-90 degrees. Also, there are double-sided nozzle, the angle of the cut which is 120-135 degrees.

- The Tail. The cross section has a hexagonal shape so that the drill bit securely fixed in the chucks of a drill and a screwdriver. In addition, the nozzle can be installed in a magnetic adapters and extension cables.

Dimensions of the working part

In the process of making tools is taken into account, the ratio of thickness and width of their cutting parts. For drills with a width of 5 to 10 mm is permitted is the thickness of 1-2 mm. If the diameter of the pen drill is 1-2 cm, the tool should have a thickness of 2-4 mm. When the width of the cutting part more than 2 cm, its thickness must be equal to 6-8 mm.

Dimensions pen drills

With this tool, you can easily take the hole diameter from 25 mm to 6 cm. Judging from the consumer reviews, most popular are the feather drills on a tree 50 or 60 mm. If you need to cut a hole whose diameter exceeds 6 cm, the master will have to use other drills, because the pen is not adapted to cover large areas.

Color

In the process of making drills for the tools provided by the implementation of the finishing processing. Its objective is to give the product increased durability. In the production used several processing options. Each of them gives the product a defined operational characteristics. In the process, the surface of the drill bit be coated by the color which can be judged about the performance characteristics of the tool:

- Nozzle of black colour have high strength. In the production for their finishing is applied superheated steam.

- Drill Golden yellow color missing, metal voltage.

- Bright Golden nozzle are processed with titanium nitride, thereby increasing the service life of products.

- Gray have tools that have not been finished.

When you purchase a feather drills on a tree, consider this aspect.

What to look for when buying?

Those who wish to purchase pen drill, qualified experts advise you to pay attention to the following points:

- The Instrument must have a symmetrical configuration.

- Equipped with a smooth cutting elements. The latter is a clear indication that the cutting nozzle is factory and not handicraft model. Pen drill bits and cutting parts have a high degree of severity and meet the standards only if they are made exclusively in the factory.

- A cursory inspection the buyer should make sure that the surface of the drill there are no defects in the form of chips or irregularities.

Advantages

The advantages of pen cutting attachments include:

- Low cost. The price of the instrument in the range of 50-120 rubles. The cost will depend on used in the manufacture of the nozzle technology of finishing processing.

- Collection of feather drills on a tree completed cutting products, diameters of which range from 5 to 60 mm.

- Due to the design of the tool it can be extended to 300 mm, using for this purpose a special attachment.

- The Drill is easy to operate.

- In the case of wear of its cutting part of the master in the home can always sharpen it. With the exception of those cases when the pen drill is too worn out.

Disadvantages

Despite these strengths, the pen bit for woodwork, they are characterized by a single minus. It consists in the fact that this tool has a limited cut diameter not exceeding 6 cm resulted In the drilling process involved only end notched incisors. When this occurs, the contact of the rounded sidewalls of the drill bit with edges of the groove, which are formed of wood fiber. As a result of surface holes turn out rough and not neat. Judging from the few reviews, these cutting nozzles at the tree very quickly become dull, and they often have to re-sharpen.

How to work the nozzle?

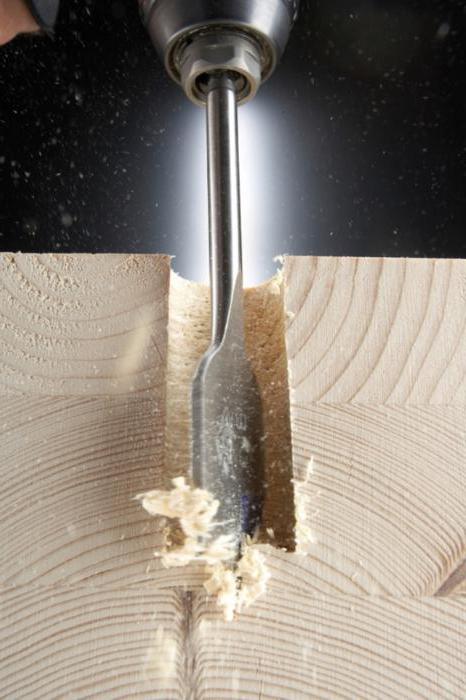

After buying the pen set of drills to choose from the packing nozzle to the desired diameter. To work with this cutting tool is recommended, adhering to step-by-step instructions:

- Before you drill a hole in a wooden surface, it is necessary to mark it. The label is applied at the point where the hole.

- Experienced masters recommend to run these drills, using a drill that has a power regulator. It is desirable that the tool used could carry 200-500 rpm. If you need to cut a hole of larger diameter the number of revolutions should be small. Judging by the consumer testimonials, drill pen on wood 50 mm will be much more effective in its job at lower rpm. With decreasing diameter respectively increase and momentum.

- To perform a deep hole, it is recommended to equip with a Keyless Chuck drill with a special adapter. In that case, if you need to drill a slight depth, a master can immediately lock the cutting head in the tool.

- Hold the power tool with a nozzle to the place where it will be drilling. In relation to the marking drill bit must be positioned perpendicularly.

- To Start, gradually increasing the speed. It is recommended to periodically remove the drill from the hole. This is due to the claim that the deepening of the accumulated wood shavings. Taking out the drill, it creates an opening for the exit to the outside of the wood waste.

- The Job is finished, if the cutting tool is deepened to the desired master level.

How to sharpen a tool?

Judging by the feedback, to implement the sharpening pen cutting tools is easy.

You'll need a diamond wheel mounted on a grinding machine. If such equipment is not available, the home craftsman can use qualitative rule. Sharpening will be easy and fast if you adhere to the following sequence:

- Prepare an unused cutting head. It will be used as a sample.

- In the course of sharpening, periodically check to be processed cutting head geometric parameters unworn new tool.

When hovering the pen on the cutting edges of a drill is recommended to be as careful. Importantly, after the sharpening was not damaged the Central projection of the instrument.

Article in other languages:

BE: https://tostpost.com/be/hatn-tul-nasc/2272-per-evoe-sverdzel-pa-dreve-pamery.html

DE: https://tostpost.com/de/gem-tlichkeit/2270-getr-nke-bohrer-f-r-holz-ma-e.html

KK: https://tostpost.com/kk/domashniy-uyut/2273-per-evoe-sverlo-po-derevu-m-lsher.html

PL: https://tostpost.com/pl/komfort-domu/2276-ko-dry-wiert-o-do-drewna-wymiary.html

PT: https://tostpost.com/pt/o-aconchego-do-lar/2273-um-broca-de-rvore-dimens-es.html

TR: https://tostpost.com/tr/domashniy-uyut/2278-ku-t-y-matkap-a-a-boyutlar.html

UK: https://tostpost.com/uk/domashn-y-zatishok/2275-ploske-sverdlo-po-derevu-rozm-ri.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Fire-retardant treatment of wooden structures attic: features

the Attic is one of the most fire-dangerous places in any building. It is here most often focus complex wiring harness assemblies for the whole house. The event of the slightest circuit is extremely dangerous for the object. That ...

grill Pan "Tefal" is an excellent replacement of conventional grill. With its help you can prepare delicious meals even in working life, when there is no possibility to leave on the nature. Each dish is prepared with the...

Metal detector "Fisher": features, reviews

a metal Detector is the device that allows its owner to find metal objects of different sizes and at different depth. The parameters depend on the modification of the device.the remainder of this article will examine why you need ...

Crusher for wood: with their hands to make very simple

Today there are many devices which greatly facilitate the daily care of the garden and the house. Is not excessive and the wood chipper. Own hands to make such a device almost everyone can. Using this unit can grind solid objects....

Pereyemnaya machine with his own hands: device drawings

Plucking poultry – it's not the most pleasant. Well if you want to remove the feathers from several carcasses. And if you need to process the 300 pieces, for example? With such a grueling task even the whole family can not c...

Effective means of self-defense

the Modern world is far from ideal. Violence and aggression among civilized society is no exception. And increasingly widespread. To predict where and when there will be another conflict of interest is almost impossible, so the pa...

Comments (0)

This article has no comment, be the first!