Now - 23:35:47

Rolling machines: overview, types, characteristics

Rolling machine is an essential equipment in obtaining metals in the form in which it is needed. About them will be discussed in the article.

General information

To date, the metal is the most common material from which made a huge variety of things, ranging from small household items to large industrial facilities. However, there is a very important point, about which not everybody knows. Just to smelt the metal, and then turn it into a ingot is not enough. After the formation of the ingot of any metal is transferred to the rolling mill. The only equipment that is available in such shops is the rolling machines. These devices and give the desired shape, which is suitable for subsequent metal application. It should be noted that this equipment is one of the oldest to date. However, over the years of its use, the machine has proved to be so good side, has such a good performance and increased productivity that it is used to this day.

Device machine

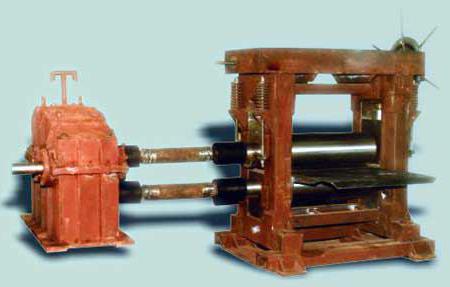

In fact, the device of the rolling machine is not complicated or difficult to maintain, build or repair. The only purpose of this device is that it gives shape to the ingot metal. In other words, in a rolling mill comes the big bars, and while passing through a rolling-mill, he gives them a form more familiar to the sheet metal. To achieve this effect, the design of the rolling machine has two rollers, which continuously rotate in the direction of each other. From the point of view of technological process it is considered pretty simple. Besides, constant improvement of technology has allowed us to make many improvements and modifications in the operation of this device. With these changes currently, all equipment of this type can operate in fully automatic mode.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Rolling

Rolling machine for metal performs another important function. It not just gives leaf shape. With the passage of the ingot through the machine the metal becomes more uniform and denser in structure. This is due to the fact that the rollers completely overwritten or close all cracks or empty spaces that could be formed on the ingot.

Another important point - the process of turning or rolling of the metal in sheet form takes place in several stages and involve several types of machines. Primary rolling and doing bluemovie Kabirova device. It should be noted that before sending the ingot to rolling on these machines, it must be warmed up a little. Increasing the metal temperature will increase the plasticity of the material while rolling. If we talk about the performance of these machines, it is huge. One machine is able to produce about 6 million tons of metal per year. Given the fact that the weight of the bars coming to hire, can be in the region of from 1 to 18 tons.

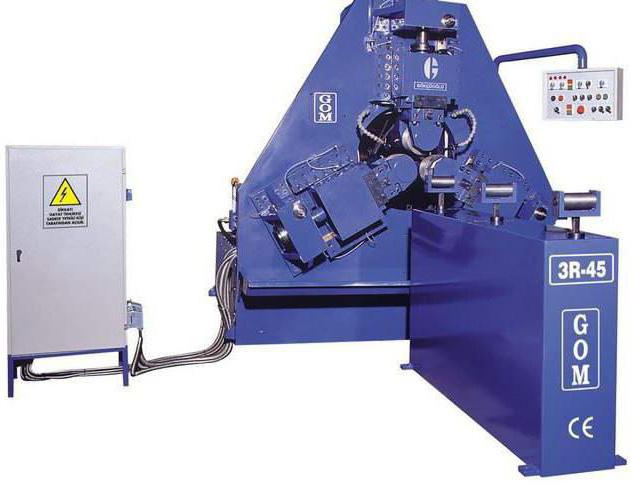

Blooming or slabbing mill

Before you go on rolling, ingots are heated in special chambers. Temperature, which is kept in these devices, can reach 1800 degrees Celsius. After passing the well used electric car, which, in fact, gives a pre-heated ingot to the rental of the blooming or slabbing mill. The difference between these machines is that blooming has only two rollers, but the slabbing four. It is important to understand that the completion of this stage and the machining process are only primary, as the output from a blooming or slabbing mill ingot still has a form of sheet material. These units are intended to form the bars. Depending on its shape and size, the resulting material is separated into blooms or slabs. Important note - the use of blumenhofer or kabirovich rolling machines is carried out only on those industrial sites where metal will later be poured into molds.

General characteristics of the machine

Rolling mills device with smooth rollers, through which pass the metal to give it sheet form. Currently there is a huge range of these devices. The biggest difference between the machines is in the form of rolls. For example, there is a unit which originally made under the production of rail. The shape of its rollers still in production machine have been prepared under this task. It is also important to understand that the machine has several pairs of rollers through which the metal. Continuous progress has led to the fact that all types of devices able to operate in a continuous automatic mode. The rate at which crates stretch the ingot through the machine, may reach a record 290 km/h. Performance of such a rolling mill a year up to several million tons. To date, more commonplace these units as casting and rolling. The advantage is that they can act as a full separate production line, in contrast to conventional rolling mills.

Incurrently there are types of machines like billet, sheet, strip, varietal, and some species are capable of producing wire or beam.

Pipes

Another large category of rolling mills intended for production of non sheet metal and metal pipes. There are three main types of rolling machine for tubes that are currently in use. These include piercing, flattening and finishing machines.

If we talk about piercing mills, they can be three different types of cylinders used to perform rolling. There are barrel-shaped, mushroom-shaped and disk rollers. The device having the first type, that is, barrel-shaped, characterized by the fact that these elements have the form of a double taper with a diameter from 450 to 1000 mm. Both parts are arranged in a horizontal plane, but the vertical axis can be adjusted the angle of flow from 5 to 18 degrees and more.

Screw-hire

Rolling machine for shaped tube can also screw the metal processing industry. When performing this type of operation rolls with double cone in the metal create tensile and shear stress. It is important to note that radial tension of the workpiece can reach quite large values, which creates a cavity of small diameter, which has uneven walls. In order to obtain a hole with the required diameter and to avoid the presence of irregularities, and to make a smooth wall, it is necessary to hire on the mandrel. Under the mandrel understand the tool a conical shape, which is located on the end of the rod between the rollers along the path of movement of the workpiece metal. For fastening of a rod with such a mandrel has a special emphasis. When the metal moves forward, it is this socket that goes through the hole, expanding and aligning it.

The car was clean on the machine for profile pipes collect quite problematic since these units are used mainly only in large enterprises. Here, however, the use of these units already talking about the fact that they work consistently and well. In other words, conclusions can be drawn based on the fact that a huge amount of time all the Metalworking factories use these machines. This means that the presence of automatic mode and huge performance doing their job. The disadvantages include the fact that the dimensions of such devices are quite large and are stopped and a new run is very problematic.

Tocotronic rental

It is Worth noting that with the passage of the hire for tufting machines out of thick-walled shells. After completing the processing on this device the workpiece is passed in Tocotronic rental on a device CAC:

- Piligrimy;

- Avtomaticheskij;

- Nepreryvnyi;

- Trekharkovy.

The Name of each of these units is determined by the type reeling mill, which is used on this equipment.

Rolling-cutting machine

The Most famous manufacturer of this unit is the company Kadzama. Another is a device called a roller press. Device this thing is very simple, and it is meant for cutting cardboard, paper or plastic boxes under confectionery.

The advantages of this device include the fact that it pays for itself pretty quickly. The first 10,000 boxes - this is the approximate cost of one such machine. The cost of finished goods i.e. cartons, also very small. To pay only for the actual source material - cardboard. To work with this type of machine is very simple. All that is needed is two things. First put a piece of cardboard on the cutting knives, and then turns the feed knob. The dimensions of this device are also quite small. You can install it even on a normal table.

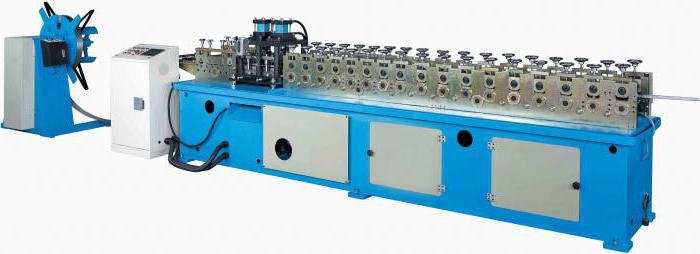

How to make a rolling machine?

To make a rolling machine for the production of profiles, you will need 3 important things to have is a metal, bearings and lathe. The construction of the machine is also quite simple. The components of the whole rolling machine is a table to which is attached a worm gear motor. In addition, it is necessary to fix on the table 7 additional acceptance stands. It is important to know what each crate consists of several parts, and they all have meshed together. That is, each crate is connected with the following. Another caveat concerns the rollers. This model of machine they are removable, and their attachment is carried out on the shafts. This type of location and the type of rollers opens up opportunities for the production of different profiles on the dimensions and type of product. If desired, you can put new rollers that will allow for the manufacture of light steel thin-walled profile. In order to avoid mistakes during manufacturing, it is best to make a drawing rolling machine before its Assembly.

Article in other languages:

AR: https://tostpost.com/ar/business/9545-rolling-machines-overview-types-characteristics.html

BE: https://tostpost.com/be/b-znes/17142-prakatnyya-stank-aglyad-v-dy-haraktarystyk.html

DE: https://tostpost.com/de/business/17151-geliehene-maschinen-berblick-typen-eigenschaften.html

ES: https://tostpost.com/es/negocio/17159-alquiler-de-m-quinas-sinopsis-tipos-caracter-sticas.html

HI: https://tostpost.com/hi/business/9549-rolling-machines-overview-types-characteristics.html

JA: https://tostpost.com/ja/business/9549-rolling-machines-overview-types-characteristics.html

KK: https://tostpost.com/kk/biznes/17138-prokat-stanoktary-sholu-t-rler-sipattama.html

PL: https://tostpost.com/pl/biznes/17118-wypo-yczalnia-maszyn-przegl-d-rodzaje-cechy.html

TR: https://tostpost.com/tr/business/17148-haddeleme-makinalar-genel-bak-e-itleri-zellikleri.html

UK: https://tostpost.com/uk/b-znes/17133-prokatn-verstati-oglyad-vidi-harakteristiki.html

ZH: https://tostpost.com/zh/business/10410-rolling-machines-overview-types-characteristics.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Grease tsiatim: characteristics, application, properties

today, lubricants are used quite widely, and the diversity of the product market is sufficiently large. One of the good domestic products was the grease tsiatim.General informationone thing Worth mentioning is that the varieties o...

As pasynkovat eggplant in open field and greenhouse?

Gardeners know how important it is to pasynkovat and to shape tomatoes, cucumbers and peppers. But should pasynkovat eggplant? "Purple" is a rather capricious plant, which, without giving them proper attention will make a good cro...

Cover crops: when to plant phacelia

Phacelia – annual, excellent bee plant, as well as green manure, i.e. it can be used to improve the quality of the soil. In addition, the planting of this plant helps to rid the area from such pests as nematodes and wireworm...

Milking machines for cows: type, device characteristics

the Popularity of agriculture among the population is again growing, and livestock keeping for many people in the private sector is the norm. Along with this and to buy a home fresh milk becomes easier, due to the content of priva...

Magnesium sulphate (fertilizer): the instructions for use, price

For a quick and proper development of vegetable and garden plants need various types of micro - and macronutrients. In addition to the nitrogen, phosphorus and potassium, plants need to obtain from the soil, and magnesium. To achi...

Rostov-na-Donu: shopping malls of the city

Rostov-on-don is considered the largest city in the South of Russia. Since 2000, he has acquired the status of administrative center of southern Federal district. Rostov-on-don is among the ten largest cities in Russia by populati...

Comments (0)

This article has no comment, be the first!