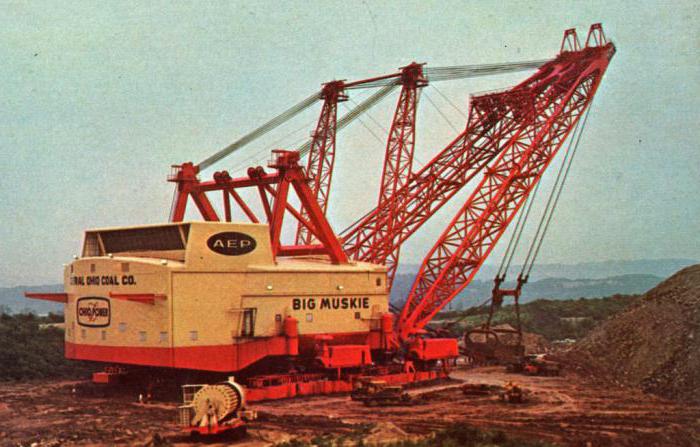

Dragline excavator: technical features, description and reviews

Excavator – earth-moving machine of cyclic operation, is designed to separate the soil from the array, moving it and loading. The main working body of the equipment is a bucket that is moving relative to the develop of rock using traction mechanisms of the machine. The Excavator may be of the type called "shovel" (designed for the development of the rock above the standing grounds), “hoe” (used to retrieve the earthen mass below the surface of the support) and the dragline-an excavator with a "scrubbing" of the bucket. The latter type is indispensable for the development of a large volume of soil during Stripping, reclamation and hydro-technical construction, to clean the bottom of rivers, lakes and other water bodies.

The Excavator may be of the type called "shovel" (designed for the development of the rock above the standing grounds), “hoe” (used to retrieve the earthen mass below the surface of the support) and the dragline-an excavator with a "scrubbing" of the bucket. The latter type is indispensable for the development of a large volume of soil during Stripping, reclamation and hydro-technical construction, to clean the bottom of rivers, lakes and other water bodies.

Excavator-dragline

The First circuit diagram of a dragline was developed in the 16th century, the great scientist of the Renaissance-Leonardo da Vinci. In industrial scale this type of technology has been used since 1884 in the United States. In Russia this type of earth-moving machines first appeared in the postwar years. They were used for mining minerals. Dragline excavator, in contrast to other models of special equipment separates rock from the array by dragging the bucket along the surface and not the action of hydraulic or rope-block system. Due to the flexible rope fastening the bucket to the boom of the dragline performs its work at a much greater distance and greater depth from the traction mechanism than other types of machines. This is both the advantage and the main difference between this type of earth-moving equipment.

Dragline excavator, in contrast to other models of special equipment separates rock from the array by dragging the bucket along the surface and not the action of hydraulic or rope-block system. Due to the flexible rope fastening the bucket to the boom of the dragline performs its work at a much greater distance and greater depth from the traction mechanism than other types of machines. This is both the advantage and the main difference between this type of earth-moving equipment.

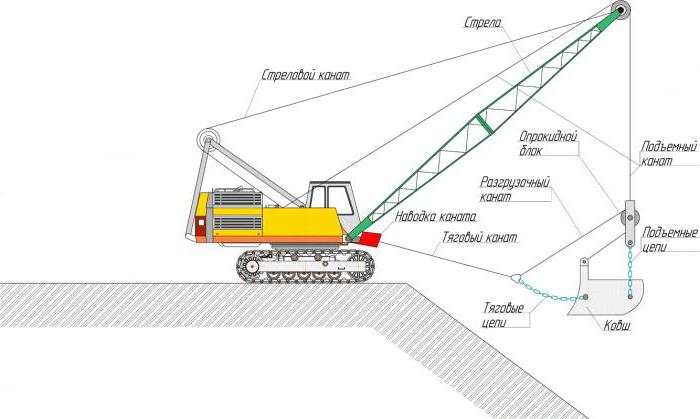

Design and operation

Dragline consists of several major systems – machine that creates traction, arrows, rope and bucket system. Part of the cable system includes a traction and lifting device, using chains attached to the bucket. The first is required to move the working body in the vertical plane, and the second pulls the bucket to the machine, whereby the cutting of the rock, and loading of the soil. Then the dragline excavator at the same time tightens and lifting and traction ropes, which increases the distance between the hinged block and the connecting element, is pulled, unloading the rope. In the result, the front edge of the bucket lifts up, which makes sleep dialed the ground.

Then the dragline excavator at the same time tightens and lifting and traction ropes, which increases the distance between the hinged block and the connecting element, is pulled, unloading the rope. In the result, the front edge of the bucket lifts up, which makes sleep dialed the ground.

After you move the soil massif to the place of unloading stress on traction and lifting ropes sharply decrease, thereby weakening the tension of the cable handling – the bucket loses balance, rolls over a shipment of rocks.

Features

The Penetration of the bucket into the soil occurs only under its own weight. Therefore, to provide a high pressure, rocks should be fairly loose. So dense and hard-rock soil that are to be developed, using a dragline excavator, pre-loosen the wedge or baking powder in blasting operations.

During operation, and the traction and lifting ropes must be in constant tension which is necessary to avoid overlapping. Lifting and lowering the boom also occur by the operation of the tether mechanism. Therefore, when working with a solid and dense ground set the buckets of a smaller size, so as not to exceed the maximum capacity.

Advantages and disadvantages

Unlike conventional excavators, which traction force is produced by the hydraulic or rope-block systems, and the bucket is rigidly connected with the arrow, the working body of the dragline moves freely relative to the main machine. This allows you to put it to great depths (several times more than they can afford conventional models).

Due to the light and the long boom, the development of soil excavated-dragline can be carried out at a significant distance from the occupied point. This increases the performance of this type of equipment and reduces the cost of the contractors. In addition, judging by the reviews, a simple and durable mechanism of crowd allows to reduce costs of ongoing maintenance of equipment.

Cons of the dragline due to the flexible suspension of the bucket. Because it decreases the accuracy of the digging and unloading. As a result, shipment of rocks directly invehicle difficult. Most often, the backfilling is performed in the blade-where it is moved in trucks. Therefore, the development of excavation array without additional special equipment – conventional excavators, forklifts – impossible.

Technical features

In order For the excavator with a dragline equipment showed the best performance, place of excavation must be directly in front of the car. Move the bucket to the bottom can occur by the pendulum method – experienced driver, swinging the working machine capable of “throw” him at a greater distance than can an arrow.

Depending on the model of this type of earth-moving equipment, the machine features will be in the following ranges:

- Boom length – from 15 to 100 meters;

- Main bucket capacity – from 6.3 to 168 mZ;

- Maximum radius of digging-15,3 meters or more;

- Ground pressure – 0,06-0,255 MPa.

Distinctive characteristics of the excavator dragline-operating weight. The weight of the lightest machines several times more machinery, hydraulic or rope-block system. This restricts their range of application.

Scope

The Reviews say that excavators-draglines are often used in areas for large-scale development of a soil massif. They are actively used during overburden removal and mining and quarries create a large radius and depth. Dragline with a perforated ladle is used for the extraction of rocks from the bottom of the ponds and for cleaning of rivers, lakes, or during the construction of hydraulic structures. They are also widely used in reclamation works. In urban environments such earth-moving machines are operated very rarely.

Dragline with a perforated ladle is used for the extraction of rocks from the bottom of the ponds and for cleaning of rivers, lakes, or during the construction of hydraulic structures. They are also widely used in reclamation works. In urban environments such earth-moving machines are operated very rarely.

Toilet seat

In recent years increasingly used walking excavators-draglines. They are delivered to the site unassembled, where their subsequent Assembly. This machine is the main time is located on the flat area. If you need to move to a new location the operator of the excavator-dragline down special shoes that support the weight and lift the car.

After that, the base platform moves, and the technique again "sits" on it. The shoes are set in a new location, and repeat the process. Typically, draglines have a large mass, which cannot withstand caterpillar mover. A Crawler or rubber-tired excavators-draglines is now almost never occur. Usually they are small machines with low performance, why use them at construction sites is impractical. Almost all representatives of this species supplanted by hydraulic and rope-block machines.

A Crawler or rubber-tired excavators-draglines is now almost never occur. Usually they are small machines with low performance, why use them at construction sites is impractical. Almost all representatives of this species supplanted by hydraulic and rope-block machines.

Producers

“Uralmash” – domestic engineering company, which in different parts of the world become the excavator-dragline. Technical characteristics of the models are in a wide range that allows each customer to choose the machine according to their needs. Judging by the reviews, this is one of the most reliable stepper representatives of machinery.

The competition for the domestic companies is only diversified Japanese company that promotes on the global market for crawler models. As a rule, it is more lightweight technique that is used in the development of relatively small samples.

Article in other languages:

JA: https://tostpost.com/ja/business/5496-dragline.html

PL: https://tostpost.com/pl/biznes/9749-draglayn-koparka-dane-techniczne-opis-i-opinie.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Delay of salaries: the risks and the possible consequences.

In recent years, when economic instability is increasingly shakes the national economy, many employers are trying to save money, delay-wage workers. However, unlike in previous years, the current law is quite rigidly regulates the...

How to activate the card "LUKOIL"?

No car will not go far without fuel. Therefore, although car owners would gladly not visited gas stations, food four wheeled transport is still needed. In order not to get so upset seeing the amount on the checks, you need to beco...

the Book market in Kharkiv, which is popularly called “Beam”, or, officially, the “Paradise”, is the largest shopping center in the city selling books. Market is an independently-functioning infrastructure....

OJSC Poultry factory "Reftinskaya": description, address, products

the Food industry in Russia today has become one of the leading sectors of the economy. Throughout the country there are thousands of companies of such specialization. Is no exception in this regard and Sverdlovsk oblast. The agro...

Profile pipe: mix. Classification and standard sizes of shaped pipes

Profiled tube — a kind of steel pipe. This category of products includes a wide range of products long products. She is in high demand among construction, manufacturing, agricultural and machine-building enterprises. What is...

Care and feeding of strawberries in spring and autumn

Strawberry many gardeners call it a strawberry. Despite the fact that the latter is independent of the berry, few know him. Therefore, in the framework of this article will examine the strawberry under her name ‘strawberry&r...

Comments (0)

This article has no comment, be the first!