Now - 17:39:57

The garment industry as a branch of light industry. Technology, equipment and raw materials for garment industry

The Development of the garment industry today is heavily influenced by new technologies. At the same time in the hard conditions of the market economy to support demand for its products is possible only to those players who offer not just quality, but also original in aesthetic and design terms of the product. There are niches, involving typical methods of production of textiles, often used in household needs. Regardless of the direction of the factory, clothing industry requires participants to this market segment regular updates of the production infrastructure. Today it is not just the issue of transition to the automated line, and the task of comprehensive modernization of the technical infrastructure.

Technology clothing industry

The Technological processes of garment production can be divided into three categories: cutting, fabrication and control. The first consists of forming technology cutting charts, calculation of material, preparation of raw materials and flooring, preparation of layout patterns, etc. depending on what tasks the apparel industry to solve specific enterprise, workers are using these or other methods. For example, directly cutting of the material is realized by hand or mechanically, by cutting or punching.

Technology of garment manufacturing also represent a large group of methods. Among them are the directly sewing, thread connection, stitching, primaqiune, mastrocco seams and wystepowanie. Each operation is also implemented in several ways, depending on the working conditions of the factory.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

As for technologies to support production control, the production is usually performed a kind of revision materials for the qualitative and quantitative characteristics, followed by the grading and prepared the passport of the product. The modern garment industry is actively implementing the control steps with the use of automated equipment or special measurement tools to accurately assess characteristics of products.

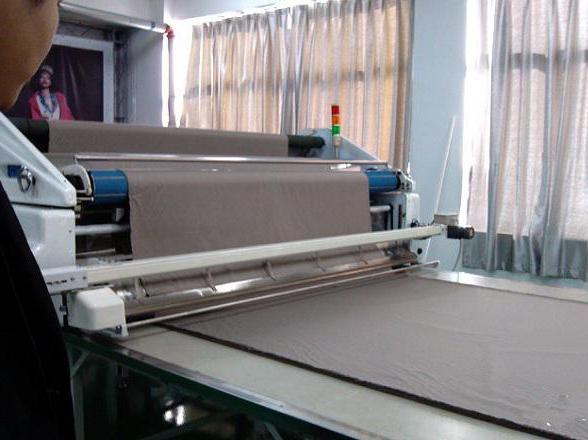

Equipment for manufacturing of apparel products

A major breakthrough for the technical modernization in the field of the garment industry happened 20 years ago, when engineers were able to achieve a sharp increase in the speed of the machines. At the moment, the existing indicators of the pace of sewing are considered optimal. Work in several modes now implementing units with thyristor control and AC drives. Thus the production process can be performed separately or as one of a group of tasks for universal installation.

For Example, there are special units for strip finishing lines at the edges oblachnykh materials. Such workpieces include cuffs, valves, collars of shirts, etc.

It is Important to stress that the technology of the garment industry in the stitching or nesting is implemented with different parameters. That is, even if the machine is focused on performing one function, the operator can specify the characteristics of the transaction in different formats.

For Example, the thyristor control implies the ability to change stitch length and direction of line that runs along the edge. In the most advanced mechanisms also provides for the ability of machines to realize automatic correction of the workflow depending on the gauges. Of course, not complete garment industry and without the accessories. This group may include units of support, fixation and transport, which implement the indirect additional function in the production process. This is usually semi-automatic machines controlled by operators themselves.

Concept related equipment kits

Practice shows that effective optimization is possible only under the condition of operation is not fragmented, but United into one set of equipment. The developers of sewing machines have been working in this direction, offering a multifunctional installation. These models perform several operations simultaneously, the output providing the product with a certain degree of readiness. Not to say that the complex method allows to cover a complete list of operations and you also can not say that aggregates are combined in one machine. Still, the concept is conditional and only shows the principle of the approach, which creates tight coupling of equipment, ultimately optimizing equipment manufacturing.

In particular, modern garment industry operates machine that enables lizirovania the armholes on the back and on the shelf, Pribivanie bag okatov setting a sleeve and other related operations in a single complex of several machines.

But it is important to consider another aspect. Although comprehensive production line, of course, provide high efficiency with minimum labor costs, they can't always compete with the traditional fragmented approach to perform technical sewingaction in high-quality settings.

Process Control

The Traditional methods of control are reduced primarily to the methods of the technical organization of individual sections of the production departments. Physically, the operation can be controlled in three ways: manual, semiautomatic and automatic. In some models of equipment provides for three modes, but this is rare – often there are two formats, one of which is automatic.

Through the user interface, the operator specifies the program that implements a particular operation with defined parameters. In particular, modern garment factory can do the layout patterns automatically in accordance with a scheme which was laid down in a computer. The schema and the commands are usually specified using the menu. Mechanical control methods also not completely out of the industry because in some cases, be more effective and economical. This applies to small businesses and individual lines where economically justified the application of automated production.

Computer technology as a management tool

Controllers and microprocessors are being actively implemented in the garment industry. It is a small device responsible for control of different technological processes. For example, a single microprocessor can simultaneously control dozens of operations.

Of Course, physically steps are performed by mechanical, hydraulic, and Electromechanical components and assemblies, which just served the commands from the controller. Original link for generating those or other decisions are sensors and detectors. This can be, for example, the device control the remaining length of thread. As its completion at the processor corresponding signal is transmitted, after which the controller gives the command for automatic tab new coil. A vivid illustration of such approaches is the mechanism for trimming threads. Armed with this equipment, garment factory without involvement of the operator can automatically reduce the length of the cut endings of the threads so that they match the thickness of the eye of the needle. Often edging the moving mechanisms are used in machines zig-zag stitch.

The operational Complexity of computerized production lies in the fact that the operator or group of staff needs to work on the details of the programme and modes of operation of controller, otherwise the slightest mistake in laying down the parameters will lead to marriage on a large scale for mass production.

Used in the production of raw materials

Sewing production requires the use of a wide range of materials, including fittings. The raw material base is formed predominantly of textile materials. These include polyester, wool, wool blend, cotton and rayon fabric. For some models of clothes also requires duplicating of materials, which includes dublerin, interlining and various lining in the form of a twill, polyester and viscose. Also in demand fur both natural and artificial origin. It is possible to tell, this is a premium raw material for clothing industry, which in the end affects the price tags of the products.

As for furniture and finishing materials, include sewing thread chapaevskoye, reinforcing fibres, buttons, rivets and various sundries. It is important to note that the hardware differs in many characteristics, even if functionally the same elements are consistent with each other. Through form, color and texture of the manufacturers of designer shades convey specific details.

Manufactured items

The Range of clothing is huge, we should not forget that garment factories do not only produce these things, but also produce technical items using the same fabrics. Anyway, the basis of the range of any garment factory is clothing, which is represented in different groups and subgroups. In particular, it can be coats, hats, pants, sundresses, swimsuits, etc.

To organize and classify your products are different symptoms. In particular, the products differ in material, shape, season, destination and other parameters. Accordingly, it is possible to classify the garment industry, which specializiruetsya in the production of certain products.

In recent years, widespread and highly specialized factories, which cover a specific segment and strive to occupy the leading place. These include enterprises engaged in manufacturing extreme clothing, uniforms, items for fishers and travellers, etc.

The Main consumers of apparel products

Most of the products necessary to cover consumer needs. The participants in this market are guided by the requests of the average consumer, offering not only clothes but also iron materials, home textiles, consumer goods. Again, specialized enterprises garment industry often cooperate with security agenciesmedical institutions and representatives of the construction sector. They offer to these groups of consumers products in the form of geotextiles, membranes, insulators, substrates and other special materials.

Specific areas, which also present their products of the garment factory, include the furniture industry, sports, tourism, and engineering. In these areas of textile production and light industry are represented only indirectly, but some products in this segment are available only with the use of textiles. For example, tourists, manufacturers offer backpacks, sun beds and tents, made of materials of high tensile strength. Big factories produce the unique technology of production of raw materials, which undergo multi-stage processing with obtaining the necessary protective properties.

Development of the garment industry in Russia

The Future of the industry depends on technological innovation, but not only they determine the direction of further development. More attention to small and large companies are giving logistics optimization. Transportation, storage of raw materials, turnover in production lines – these and other steps require maintaining high efficiency, or their organization costs unreasonably high cost. Of course, the clothing industry in Russia in recent years have advanced and the technological support. But, as opposed to foreign producers the same automated and robotic lines are often used on conveyors of large enterprises that manufacture standard products.

The Original products manufactured in small batch formats are still produced in the traditional mechanised equipment. Computerization, in turn, has an impact not only on the controls.

Through special programs of the sewing industry in Russia received the opportunity to effectively develop new design solutions within the individual production units.

Conclusion

The Success of the garment factories depend on a wide range of different factors. Among them, the level of technical equipment and the quality of the raw materials used, as well as productivity. The modern garment industry can not focus on the needs of the target audience. Some manufacturers initially choose a particular narrow niche, and other factories cover a wide audience of consumers, adjusting the production depending on the trend. Also, the approach of development greatly determines the methods of planning of activity of the enterprise.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Bridges - an essential attribute of almost every river, they help to overcome obstacles, thanks to them, distances become smaller, and to get from point "A" to point "B" is more comfortable and faster. With the advent of new mater...

Farm - what is it? Construction

the Most common meaning of the word "farm" – the agricultural enterprise is designed for livestock. But now it's not about the place of part-time farming. Here you can find all the information about probably the most ancient...

The pedestrian traffic lights: types and pictures

the Idea of installing traffic lights at street intersections to control traffic belongs to Londoner John Peak knight. By profession he was a specialist in railway semaphores.a Few historical factsthe First traffic lights were des...

Industrial beekeeping - what's required? Products for beekeeping. Courses of beekeeping

the Establishment in 1814 by the Russian beekeeper P. I. Prokopovich hive has made possible the practical application of rational methods of beekeeping. Followed in the first half of the 19th century the invention of the artificia...

Structure and purpose current transformer

the Transformers in the infrastructure systems of energy provision can have different meanings. Classic designs are used to transform individual power parameters to values suitable for carrying out measurements. There are other va...

Unlike ZAO JSC: various organizational-legal forms

In life, many are faced with various terms, for example involving the law or the economy. This is a common trend, because we are surrounded by thousands of shops, businesses, cafes, shopping centers and other places that can be ca...

Comments (0)

This article has no comment, be the first!