Now - 05:00:41

Styrofoam extruded: specifications, thickness, density, conductivity

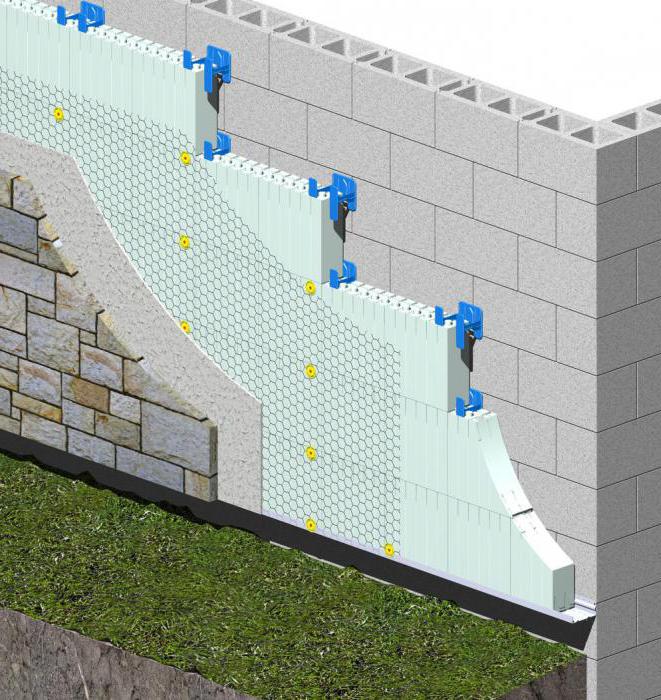

Modern construction market today is Packed with many insulating materials. They are not only features of technology, but also for its properties and purpose. However, one of the most popular is the extruded foam, which will be discussed below. It can be used not only for insulation but also to protect the building from external noise. To improve efficiency it is possible to stack material in several layers.

Description

VC has a unique insulating qualities, and in appearance resembles the foam that is used today for facade insulation. Specifications significantly exceed the performance of traditional foam. It is made out of polystyrene granules, which melt under high temperature to form a viscous state. High pressure in the chamber is pumped carbon or freon, each of which is a foaming agent. The resulting mass is extruded through an extruder and forms a certain shape.

Reference

This technology allows you to create an extruded foam which has a closed cellular structure and resists the penetration of heat and moisture. It is resistant to aggressive media type of alkalis and acids, and it can be used at extremely low temperatures that can reach -50 °C. If we are talking about the highest possible temperature, it is kept at around +70 °C.

Material Thickness

If you have decided to buy Styrofoam extruded, you should know about what its thickness. Different companies have this option differs, so you can find the plate starting from 20 mm and ending 20 see That raises the question about what thickness to choose for carrying out those or other works. For this you should know, what is the resistance to heat transfer of the materials from which objects are built in need of insulation.

There are established norms and rules that indicate the nominal resistance of heat transfer in certain regions. For example, in the center of Moscow resistance of the wall will be 4.15 m2°C/W, while for the southern regions this figure will be the maximum of 2.8 m2°C/watt.

Once you define the norm in the region, it is necessary to calculate the resistance of a material and to take it away from the norm. The resulting value will indicate the resistance of polystyrene. If you have the results in the table you will be able to determine the necessary thickness of insulation.

The density of the material

The Foam is extruded, the density of which is indicators from 28 to 40 kg/m3, presented by the brand PBS-C-40. Sometimes a manufacturer tries to enter the buyer misleading, because the production of polystyrene foam of lower density will take less money. Therefore, you should not rely solely on the number in the brand name, you need to ask about the technical characteristics that must be specified in the certificates.

Well if you tell me exactly how the manufactured material. If the density is 35 kg/m3, then it is extrusion. The usual way to achieve density, which is not higher than 17 kg/m3.

The thermal conductivity of the EP

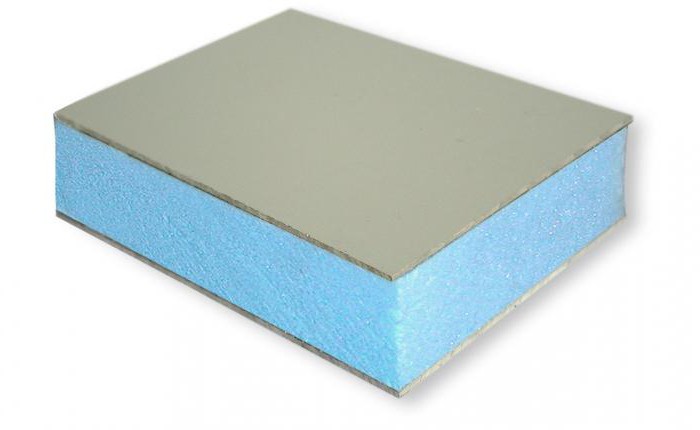

Extruded foam, the thickness of which was mentioned above, should be chosen by the consumer not only from these data, but also taking into account thermal conductivity. Described in the article insulation – a huge amount of air bubbles that are separated by a thin shell of polystyrene. In this case, the ratio is 98 % air and 2% polystyrene. The result is a semblance of a solid foam. The air enclosed inside the bubble, thus the material retains heat. The air layer without movement is an excellent insulator.

When compared with mineral wool, then the ratio of the thermal conductivity will be higher. He will be the indicators from 0.028 to 0,034 W/(m·K). The more dense will be the foam, the greater the value of the coefficient of thermal conductivity. Thus, extruded foam whose density is 45 kg/m3, this parameter is equal to 0.03 W/(m·K). However, note that the ambient temperature should not be above +75 °C and below -50 °C.

Main properties

Extruded foam, the thermal conductivity of which was mentioned above, possesses certain properties, among which an almost complete absence of water absorption and low thermal conductivity. Even if the plate is completely immersed in water for 10 days, the cells will not absorb moisture, as they are isolated, will be filled only side open cell. On the thermal conductivity were discussed above, it is worth to mention that this parameter is much less compared to other insulation materials. Plasticity is also not as high, but the fragility impressive, especially if we draw a parallel with foamed polystyrene.

The material has the ability to transmit light, and its compressive strength is high enough. The insulation is rotting and has a high resistance to frost. The extruded foam freely migrates impact:

- Acids;

- Water;

- Caustic alkalis;

- Oil;

- Bleach;

- Salt rastvorov;

- Krasitelei;

- Spirta;

- Uglevodorody;

- Cement;

- Acetylene;

- Paraffine;

- Propane;

- Butane.

Not to mention about the safety.

Specifications

Extruded foam, the characteristics of which were partially mentioned above, has a minimal water absorption, which ranges from 0.2 to 0.4%. The weight is quite small and can vary from 25 to 45 kg/m3. Among the disadvantages include poor water vapor permeability, which is 5 times lower compared to traditional foam. This value is 0,013 Mg/(m*h*PA). That increases the demands on the ventilation systems of the home to insulate extrusion polystyrene foam.

Extruded foam, the technical characteristics that are of interest to the consumer, has another flaw, which is expressed in high Flammability. The material belongs to the class G3-G4, however, today many manufacturers use special additives that allow to achieve almost non-combustible characteristics. Therefore, this insulation can sometimes be attributed to classes G1 and B1.

However if you look into the sanitary norms and rules, it is possible to emphasize that the extrusion plates which have a high degree of combustibility can be used in building structures. If the building are increased requirements for fire safety, you should use extruded polystyrene, which belongs to the group of combustibility G3.

Conclusion

Recently released Federal law on combustible thermal insulation materials, it contains information on indicators of toxicity of combustion products. For high-quality polystyrene toxicity does not exceed T2, which suggests that the insulation is moderately dangerous. This indicator is inherent in the materials of wood, such as parquet. Service life comparable with the life of a building, and high quality producers, this figure reaches 40 years.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

The vases: the history of creation and development. OJSC "AVTOVAZ"

Volga automobile plant was created in the 60-ies of the last century. This production was at the time just needed. The government with its construction sought to meet the demand of Soviet citizens in the personal car. VAZ was orig...

Kolomna diesel locomotive plant them. V. V. Kuibyshev

industrialization of the country began with the advent of the railway. And the first Russian steam locomotives were gathered in Kolomna. Kolomna diesel locomotive plant. V. V. Kuibyshev - one of the oldest enterprises of Russia. T...

What is meant by the concept of recycling? This motion of the medium in a confined space

Recycling — it's a multiple cooling, heating, cleansing of the internal environment. The advantage of surgery is the fastest and most economical way to change the settings of the air or water. Most people hear this term when...

Strategic management: types of goals.

it is believed that every organization exists in the market to perform certain tasks and meet certain requirements.in order to understand what tasks may be involved in the strategic management and what goals what kind of wants to ...

Urea formaldehyde resin: production, use and properties

urea-Formaldehyde resins are widely used in construction, woodworking and some other industries. The industrial way to produce their first started in the USA in 1927. For water resistance and strength of polyester and epoxy resin ...

Structural subdivisions of the organization: types

Structural units of the organization are the Foundation on which are based various formation. They should be possible to follow activities and to be most effective in carrying out their duties.General informationIn small organizat...

Comments (0)

This article has no comment, be the first!