Fuel pump low pressure diesel engine: basic features and purpose

The car Engine is often compared to the human heart. And the resemblance really is. Through the heart one can live and the vehicle through the motor to move. The heart pumps the blood in the body – provides circulation to all key agencies. In this engine the function of fuel system. Today we will review features and purpose of the low pressure pump. This element is a very important part of the power system. TNND needed to supply fuel to the injection pump. It is often installed near the injection pump. Both mechanisms are connected by pipes through which circulates. At the same time the fuel passes through the filters where cleaned.

What tasks does TNND in the fuel system

Fuel pump low pressure diesel engine solves an important problem.  Fuel, which is supplied under low pressure, subjected to boiling. As a result, the steam tube. The vapor bubbles of light fractions and a more dense fuel are separated. This means that the low pressure pump will start to get the fluid whose viscosity is constantly changing. On the discharge of fuel with the injection pump in normal operation, can not speak. The torch is constantly changing and will not fall into the normal parameters.

Fuel, which is supplied under low pressure, subjected to boiling. As a result, the steam tube. The vapor bubbles of light fractions and a more dense fuel are separated. This means that the low pressure pump will start to get the fluid whose viscosity is constantly changing. On the discharge of fuel with the injection pump in normal operation, can not speak. The torch is constantly changing and will not fall into the normal parameters.

How TNND

Fuel pump low pressure diesel engine consists of a drive shaft. The pumping is performed by means of a special rotor which has blades. Also, the design includes a stator, camshaft drive and driven gear. When the rotor is driven, there is a convergence of the blades with the stator. Next is the formation of cells due to a centrifugal force. As in the cavity of the pump creates a voltage, the fuel flows from the fuel pump directly to them. For this there are channels in the distribution disk. A small amount of diesel gets into the reduction valve if the pressure more than necessary.  Both devices are linked, therefore, to create and maintain the desired conditions uses a special drain choke. This nozzle, which is screwed into the high pressure pump. So, the conditions in the cells depending on the speed with which rotates the drive shaft.

Both devices are linked, therefore, to create and maintain the desired conditions uses a special drain choke. This nozzle, which is screwed into the high pressure pump. So, the conditions in the cells depending on the speed with which rotates the drive shaft.

Device transfer pump

The Primer or fuel pump low pressure (TND) in diesel power units has a simple design. It consists of two gears which are constantly in engagement with each other. During rotation, the teeth of these gears create the flow of fuel through the fuel system to the high pressure pump. The main element designs in the pump pump type-piston, which pumps fuel. To supply the diesel needs two modes of operation of the piston. It is a working progress and subsidiary.

Varieties TND

Fuel pump low pressure diesel engine – is only one kind of these mechanisms. In addition to diesel, these devices can be found in other engines, regardless of model, engine or year of production. Without a pump will not do – it is necessary to supply fuel from the fuel tank and transferring it further down the system.  In the case of carbureted gasoline motors available are relatively weak capacity mechanical pumps. On units equipped with the injector power supply system, and diesel power units use a booster pump diesel fuel electric.

In the case of carbureted gasoline motors available are relatively weak capacity mechanical pumps. On units equipped with the injector power supply system, and diesel power units use a booster pump diesel fuel electric.

Mechanical TND

This system is mounted directly on the block of cylinders and fixed by means of ordinary screws. The operation of such a pump is provided by a crankshaft eccentric. If you click on an eccentric Cam, inside created reduction. So fuel is supplied to the power system. To fuel back up, the pump is equipped with a special valve. The remaining pressing Cam send gasoline to the carburetor. If the car has TND mechanical type, then it can easily start the engine even when accounting for the long downtime. To do this, just manually pump the mechanism of paging.

Electric

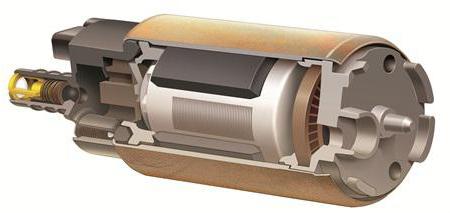

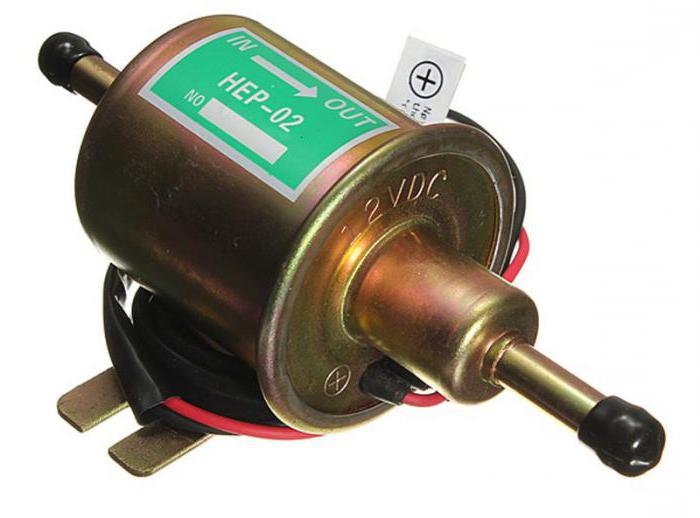

Modern cars use electric fuel pump low pressure for diesel engine and gasoline injection motor. The use of mechanical devices was impossible. He, because of less power could not cope with the settasks. It does not create the necessary pressure inside the fuel system.  Into a more simple form of the device represents itself pumping element and an electric motor enclosed in a housing. There is also a filter for cleaning the fuel nozzles and the fuel flow sensor. Scheme and principle of operation is similar to the algorithm of operation of a power unit. The only difference is that for pumping liquid used by the motor. In gasoline engines TND is located directly inside the fuel tank. Most car owners believe that it is not safe. Actually no danger in this. In the case of gasoline fuel in the pump is prone to overheating due to the heat that is emitted by the engine. Electrical analogues this problem is completely absent. Fuel without breaks moving through the pipes of the system and does not allow the pump to overheat to a critical point. In diesel engines electric TNND often combined with the injection pump. This can be explained by the need to supply fuel constantly. This ensures stable operation of the engine at different rpm.

Into a more simple form of the device represents itself pumping element and an electric motor enclosed in a housing. There is also a filter for cleaning the fuel nozzles and the fuel flow sensor. Scheme and principle of operation is similar to the algorithm of operation of a power unit. The only difference is that for pumping liquid used by the motor. In gasoline engines TND is located directly inside the fuel tank. Most car owners believe that it is not safe. Actually no danger in this. In the case of gasoline fuel in the pump is prone to overheating due to the heat that is emitted by the engine. Electrical analogues this problem is completely absent. Fuel without breaks moving through the pipes of the system and does not allow the pump to overheat to a critical point. In diesel engines electric TNND often combined with the injection pump. This can be explained by the need to supply fuel constantly. This ensures stable operation of the engine at different rpm.

Fuel high-pressure pump (injection pump)

This device is considered to be one of the most difficult in the diesel engine. Its main task is to ensure the supply of diesel to the combustion chamber under high pressure. Supply is provided not just under a certain pressure, but in the right time. The portion is very accurately measured electronically and is fully consistent with the level of load on the unit. There are several types of devices according to the type of injection. It aggregates with battery injection system and direct action.  The Device of the fuel high-pressure pump of diesel engine, which uses the direct principle of action, is characterized in that the design is the plunger, has a mechanical type actuator. Thus, the injection and the injection are performed simultaneously. Within each combustion chamber a separate section of the pump sprays a dose of fuel. The necessary pressure is provided by movement of the plunger mechanism.

The Device of the fuel high-pressure pump of diesel engine, which uses the direct principle of action, is characterized in that the design is the plunger, has a mechanical type actuator. Thus, the injection and the injection are performed simultaneously. Within each combustion chamber a separate section of the pump sprays a dose of fuel. The necessary pressure is provided by movement of the plunger mechanism.

Rechargeable pump and their features

The Pumps with accumulator injection, have differences. So, on the working drive of the plunger will act under pressure compressed gases in cylinders of the engine. Also the impact may be by means of springs. Now common device with battery hydraulic type. They are the powerful engines that run mostly at high speeds.

The Basic malfunctions of TNND

The Main problem – the reduction of device performance and the drop in the level of injection, which provided the fuel low-pressure pump diesel engine. It can be defined with the help of a pressure gauge or pressure sensor, which is installed at the entrance.  The Most common causes of performance degradation TND is a blockage and jamming of the work item. As for the first reason, the diesel fuel may contain various impurities, which may pass through the filter elements, however, still accumulate in the valve. It is also possible that decreased elasticity of the return spring element.

The Most common causes of performance degradation TND is a blockage and jamming of the work item. As for the first reason, the diesel fuel may contain various impurities, which may pass through the filter elements, however, still accumulate in the valve. It is also possible that decreased elasticity of the return spring element.

How to fix TND

In the case if you dropped the efficiency of the unit, the fuel pump low pressure diesel engine must be removed and conduct an audit. It often happens that the performance comes right back again after washing and cleansing working of the cavities and components of the device.  Also it is useful to drain the debris and tar from the drainage compartments. For more serious repairs use repair kits which are now available in the Chinese factories that manufacture spare parts for car engines.

Also it is useful to drain the debris and tar from the drainage compartments. For more serious repairs use repair kits which are now available in the Chinese factories that manufacture spare parts for car engines.

Knowing how the fuel pump low pressure diesel engine, the principle of operation of the device, you can easily fix it or replace.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Replacement of shock absorbers of the car with his hands

in order for the car was convenient and comfortable to move in, required proper operation of the suspensions. In addition to comfort, this is also necessary for safety on the roads. If suspension system is faulty, it can pull an a...

The car pulls to the left: causes. Adjustment of wheel alignment

each driver question the quality and proper operation of the vehicle in the first place. When it comes to steering and its efficiency, there is a need to be especially careful and exercise caution. Steering – one of the most...

Brake pads: replace with your own hands

in order to be sure of the safety of travel, you should always monitor the condition of the brake system of your car. And one of its main components are the brake pads. Replacement of these parts on all modern vehicles, both domes...

Idle sensor VAZ 2110, 21214, 2107, 2112, 2109, 2115

the teamwork of the internal combustion engine is possible only when the health of all its constituent parts and mechanisms. This vehicle is equipped with various sensors and subsystems, among which special attention deserves the ...

Process of operation of the vehicle forcing the driver to keep in mind the many different aspects associated with the condition of his vehicle. Most of them are reduced to internal filling under the hood, but the situation outside...

How to check the switch on the scooter, working principle and description

the Scooter is quite common today, of a vehicle, it does not require a lot of fuel, but at the same time and gives incredible speeds, which can boast of its two-wheeled brethren, motorcycles. It's quite a specific type of transpor...

Comments (0)

This article has no comment, be the first!