Now - 20:53:37

The device of the power supply system petrol engine

The internal combustion Engine is the primary source of torque and all the subsequent processes of mechanical and electronic type in the vehicle. Its functioning provides a whole range of devices. This is the power supply system of gasoline engine.

How it works, what are the breakdowns, you should consider every owner of vehicles with a petrol engine. This will help proper operation and maintenance of the system.

General characteristics

The system power gasoline engine allows to ensure the normal operation of the vehicle. To do this, inside the fuel Assembly the mixture of fuel and air. The power supply system petrol engine also stores and provides the components for making fuel. The mixture is distributed to cylinders of the engine.

In this case, the power supply system of the internal combustion engine works in different modes. First, the motor should start and warm up. Then the idle period. Engine operate partial loads. There are also transients. The engine must function properly under full load, which can occur in unfavorable conditions.

So the engine was working properly, we need to ensure two basic conditions. The fuel must burn quickly and completely. Thus formed exhaust gases. Their toxicity must not exceed the established norms.

To ensure normal conditions for the functioning of units and mechanisms, the power system fuel diesel engine must perform a number of functions. It provides not only fuel, but also makes storage and cleaning. Also, the power supply system purifies the air that is supplied to the fuel mixture. Another feature is the mixing in proper proportion of fuel components. After this fuel mixture is passed to the cylinders of the engine.

Recommended

How does the rear bushing front arm and how many it serves?

The Rear bushing front arm – one of the constituent elements of the vehicle chassis. He refers to the guide elements of the suspension together with the levers endures tremendous stress with wheels. However, with this this item, there are many ...

Oil consumption in the engine. Six reasons

It is Hardly possible to find a motorist who would not be worried about the increased oil consumption. It is especially annoying when it happens with another new motor. Here are the most common causes that result in the consumption of oil in the engi...

The exhaust System is designed to remove combustion products from the engine and output them to the environment. It also must be ensured a reduction in noise pollution to acceptable limits. Like any other complex devices, this system consists of seve...

Regardless of the type of gasoline internal combustion engine, the power system includes a number of structural elements. It includes a fuel tank, which provides storage of a certain quantity of gasoline. The system also includes a pump. He keeps the fuel, moving the fuel line. The latter consists of metal pipes and hoses made of special rubber. Thereon passes gasoline from the tank to the engine. The excess fuel also through the tubes is returned.

Supply System of gasoline necessarily has in its composition filters. They purify the fuel and air. Another mandatory element is the device that prepare fuel mixture.

Gasoline

The purpose of the system power gasoline engine is to supply, treatment and storage of petrol. This is a special kind of fuel, which has a certain level of volatility and antiknock. On its quality depends largely on the performance of the engine.

The Rate of evaporation speaks of the ability of gasoline to change their state of aggregation from liquid to vapor. This figure has a significant impact on the formation of the fuel mixture and its combustion. In the process of engine operation involving only the gaseous part of the fuel. If gasoline is in a liquid form, it affects the motor.

The Liquid fuel flows through the cylinders. With their walls washed off the oil. This situation entails rapid wear of the metal surfaces. Liquid gasoline prevents proper combustion of the fuel. Slow combustion leads to a drop in pressure. The motors can not develop the required power. The toxicity of the exhaust gases increases.

Also, another unfavorable phenomenon in the presence of liquid gas in the engine is the occurrence of soot. This leads to a rapid destruction of the motor. To maintain the rate of evaporation is normal, you need to buy fuel in accordance with the weather conditions. There is a summer and winter gasoline.

Considering the purpose of the system power gasoline engine, you should consider another characteristic of the fuel. It's knock resistance. This indicator is measured through the octane number. To determine the detonation resistance of the new gasoline compared with the reference fuels, the octane number of which are known in advance.

The composition of the gasoline are heptane and isooctane. Its characteristics are the opposite. The isooctane is missing the ability to knock. So its octane number is 100 units of Heptane, on the contrary, a strong detonator. Its octane number is 0 units. If the mixture in the course of the test consists of 92% of isooctane and 8% heptane, octane is 92.

The Method of preparation of the fuel mixture

The Operation of the system power gasoline engine, depending on the peculiarities of its construction can vary significantly. However, regardless of how it is arranged, to the nodes and mechanisms have a number of requirements.

The fuel supply System must be sealed. Otherwise, malfunctions occur in different sections. This will lead to incorrect work of the motor, its rapid destruction. Also, the system should produce precise dosage of fuel. It should be reliable, to ensure the normal functioning conditionsthe engine in all conditions.

Another important requirement, which today extends to the system of preparation of fuel mixture, is easy to maintain. This design has a certain configuration. Allowing the vehicle owner to conduct maintenance if necessary.

Today the system power gasoline engine has a different method of preparation of the fuel mixture. It can be of two types. In the first case, when mixing, apply the carb. It mixes a certain amount of air with gasoline. The second method of fuel preparation is compulsory injection into the intake manifold of gasoline. This process occurs through the injectors. This is a special injector. This type of engine is called the injection.

Both systems provide the correct proportion of gasoline and air. Fuel at the right dosage is burned completely and very quickly. At this rate largely affects the amount of both ingredients. The normal ratio in which there is 1 kg of gasoline and 14.8 kg of air. If deviations take place, we can talk about poor or rich mixture. In this case, the conditions for proper operation of the motor deteriorate. It is important that the system provide a normal quality of fuel delivered to the engine.

The Procedure takes place in 4 cycles. There are also two-stroke gasoline engines for automotive vehicles they not apply.

Carb

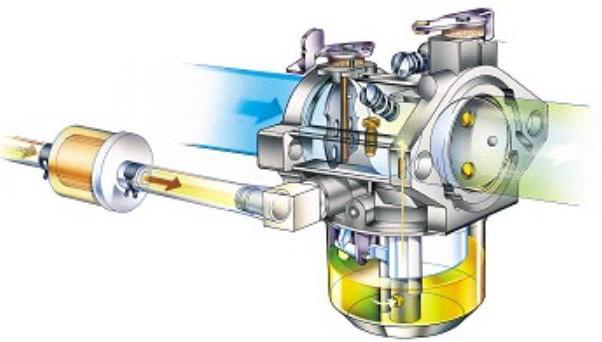

Power System gasoline carburetor engine based on the action of the complex unit. He mixes gasoline and air in certain proportions. This carburetor. Most often it has a float configuration. Design includes a camera with a float. Also, the system has a diffuser and atomizer. Fuel is prepared in the mixing chamber. Also the design has the throttle and choke channels for the feed ingredients mixture with the jets.

The Ingredients are mixed in the carburetor on passive principle. When the piston moves in the cylinder creates a low pressure. In this empty space directs the air. It first passes through the filter. In the mixing chamber of the carburetor, the formation of the fuel. The gasoline that comes out of the dispenser, the diffuser split the air flow. Further, these two substances are mixed.

Carburetor type of design includes different metering device, which sequentially during operation. Sometimes a few of these elements operate simultaneously. Depends on proper operation of the unit.

Then through the intake manifold and valves fuel mixture enters the cylinder of the motor. Now this substance is ignited under the influence of a spark the spark plugs.

Power supply System of gasoline engine carburetor type, also called mechanical. Today it is almost used to create the motors of modern cars. It cannot ensure the implementation of existing energy and environmental requirements.

Injector

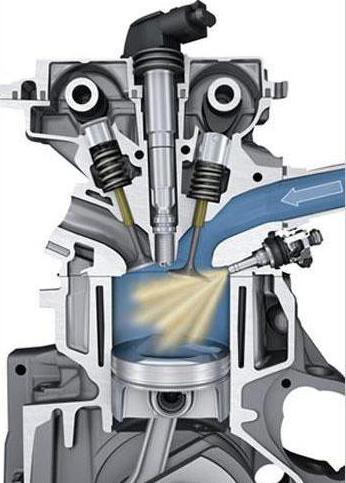

Injection engine is a modern design engine. It is much more than all indicators of a carburetor of the power supply system of a petrol engine. The injector is a device which ensures the fuel injection in the engine. This design enables a high engine power. The toxicity of the exhaust gases is greatly reduced.

Fuel injected engines have the stability. The car during acceleration, demonstrates superior dynamics. The amount of gasoline that is required in the vehicle for movement will be significantly lower than the carburetor of the power system.

In the presence of a Fuel injection system burns more efficiently and fully. The system management processes are fully automated. Manually do not need to make settings of the unit. Injector and carburetor is considerably different design and principle of operation.

The Injector power supply system of a petrol engine incorporates a special nozzle. They are under the pressure of the injected gas. Then it is mixed with air. This system allows to save fuel consumption, increase engine power. It increases to 15% if compare with petrol engine types.

The injection Pump motor is not mechanical as it was in the carburetor designs, and electric. It provides required pressure with the injection of gasoline. The system supplies fuel to the right cylinder at a certain time. The whole process control on-Board computer. Using sensors, it assesses the quantity and temperature of the engine and other parameters. After analyzing the gathered information, the computer decides on fuel injection.

Features injection system

The Injector power supply system petrol engine may have a different configuration. Depending on the design features of the device are presented to the class several types.

The first group includes engines with single point fuel injection. This is the earliest development in the fieldfuel injection engines. It includes only one nozzle. It is located in the intake manifold. This injector injector distributes fuel for all cylinders of the engine. This design has several disadvantages. Now it is practically not used in the manufacture of gasoline engines of vehicles.

More modern kind has become a distribution type injection design. For example, such a configuration of the power supply system in petrol engine «Hyundai X 35”.  This design has a header and several individual nozzles. They are mounted above the intake valve for each cylinder separately. This is one of the most modern varieties of the fuel injection system. Each nozzle delivers the fuel to a separate cylinder. From there, the fuel enters the combustion chamber.

This design has a header and several individual nozzles. They are mounted above the intake valve for each cylinder separately. This is one of the most modern varieties of the fuel injection system. Each nozzle delivers the fuel to a separate cylinder. From there, the fuel enters the combustion chamber.

Distribution injection system can be of several types. The first group includes devices simultaneous fuel injection. In this case, all injectors simultaneously inject the fuel into the combustion chamber. The second group includes mutually-parallel system. Their injectors are opened by two. They are set in motion at some point. The first nozzle is opened before the injection stroke, and the second – just before a release. The third group comprises a phased array distribution system of injection. The injector opened before the injection stroke. They inject pressurized fuel directly into the cylinder.

Device injector

Power supply System of a petrol engine with fuel injection has a particular device. To make the maintenance of such engine by yourself, you need to understand the principle of its operation and design.

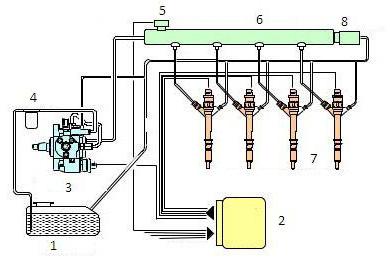

The Injection system is composed of several mandatory elements (diagram provided below). it includes an electronic control unit (Board computer) (2), the pump (3), injectors (7). There is also a fuel rail (6) and pressure regulator (8). Be sure the system control temperature sensor (5). All these components come together to interact in a specific pattern. Also, the system has a tank (1) filter and clean gasoline (4).

it includes an electronic control unit (Board computer) (2), the pump (3), injectors (7). There is also a fuel rail (6) and pressure regulator (8). Be sure the system control temperature sensor (5). All these components come together to interact in a specific pattern. Also, the system has a tank (1) filter and clean gasoline (4).

To understand the principle of operation of the presented power system, you need to consider the interaction of the elements presented in the example. New cars are often equipped with a fuel injection system with multipoint multiple point injection. When starting the motor the fuel supplied to the fuel pump. It is located in the fuel tank as fuel. Further, the fuel under a certain pressure enters the highway.

The rail mounted injectors. It is the supply of gasoline. Rail there is a sensor that regulates the fuel pressure. It determines the air pressure in the injectors and the intake. The sensors transmit information to the onboard computer system status. He sinhroniziruete the process of filing the components of the mixture, adjusting the number for each cylinder.

Knowing how the injection process can be carried out independently maintenance of the power supply system of gasoline engine.

Maintenance carburetor systems

The Maintenance and repair of devices of the power supply system petrol engine can produce with their hands. For this you need to perform a number of manipulations. They are reduced to checking the fastenings of the pipes, the tightness of all components. Also assesses the condition of the exhaust system, pull the throttle actuators, air dampers carb. In addition, the need to control the state of the stop of the crankshaft.

It may be necessary to carry out pipeline cleaning, replacement of seals. Feature of the maintenance of the carburetor is the necessity of its setting in spring and autumn.

In some cases, the cause of deterioration of gasoline motor can be faulty in the other nodes. Before starting maintenance of the fuel system you need to check the other machine components.

Malfunction of the power supply system of gasoline engine carburetor type can be checked while running and the engine off.

If the motor is switched off, you can measure the amount of gasoline in the tank, and also the condition of the sealing elastic under the tube neck. It also assesses the fastening of the gas tank, fuel line and all its elements. Other elements of the system should also check the strength of fasteners.

Then you need to run the motor. Checked for leaks at the connections. You should also assess the condition of the filters and sedimentation tank. The carburetor must be properly configured. In accordance with the manufacturer's recommendations is the selection of the ratio of air and gasoline.

Frequent malfunction injector

Repairing the fuel supply system petrol engine type injector is a bit different. There is a list of common malfunctions of such systems. Knowing them, to ascertain the cause of incorrect operation of the motor will be easier. Over time, out of order, sensors that monitor various indicators of the state of the system. Periodically they need to be checked for serviceability. Otherwise, the onboard computer will not be able to choose appropriate dosage and mode of fuel injection.

Also with time in the system dirty filters or even the injector nozzles. This is possible withusing gasoline of poor quality. Periodically the filter needs to be changed. You also need to pay attention to grid cleaner fuel pump. In some cases it can be cleaned. Every few years you need to wash the tank. At this point it is also advisable to change all filters.

If, over time, will clog the injector nozzles, the engine will lose power. The consumption of gasoline will also increase. If time does not resolve the issue, the system will overheat, valves will burn out. In some cases, the injectors may not be closed tightly. It is fraught with excess fuel in the combustion chamber. Gasoline will mix with oil. To prevent adverse consequences, the nozzle must be periodically cleaned.

Power supply System petrol engine type injector may require flushing of the injectors. This procedure can be accomplished in two ways. In the first case, the injection nozzles do not disassemble from the car. Through them is passed a special liquid. The fuel line should disconnect from the rail. With a special compressor washing liquid is fed into the nozzle. This allows you to effectively clean them from dirt. The second option of cleaning involves the removal of the injectors. Then they are treated in a special ultrasonic bath or on a wash stand.

Expert Advice

Experts recommend that you consider that feed system of a gasoline engine in the operating conditions on the Russian roads subjected to high loads. Therefore, maintenance need to produce often. Fuel filters need to be changed every 12-15 thousand kilometers, clean the injectors every 30 thousand km.

It is Important to pay attention to the quality of fuel. The higher it is, the more durable will the work of the engine and the entire system. Therefore, it is important to buy gasoline in the audited points of sale.

Having Considered the peculiarities of the structure of the system power gasoline engine,one can understand how it works. If necessary, maintenance and repairs can be made with their own hands.

Article in other languages:

AR: https://tostpost.com/ar/cars/21116-the-device-of-the-power-supply-system-petrol-engine.html

HI: https://tostpost.com/hi/cars/23435-the-device-of-the-power-supply-system-petrol-engine.html

PL: https://tostpost.com/pl/samochody/40632-urz-dzenia-uk-adu-zasilania-silnika-benzynowego.html

PT: https://tostpost.com/pt/carros/40301-o-sistema-de-alimenta-o-do-motor-a-gasolina.html

UK: https://tostpost.com/uk/avtomob-l/39652-pristr-y-sistemi-zhivlennya-benzinovogo-dviguna.html

ZH: https://tostpost.com/zh/cars/48113-the-device-of-the-power-supply-system-petrol-engine.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

"IZH 350 Planeta Sport" – frisky Soviet bike

it is believed that of the entire line of Soviet motorcycles "IZH" truly sporty just one. It is easy to guess that it was "IZH 350 Planeta Sport".History motorcycleIn 1973 the factory "Izhmash" was made a real breakthrough: the li...

Powder coating disks. NAYADA: services, rates, reviews

Many motorists after some time thinking about painting the wheels of his car. Someone wants to give your vehicle an original look, someone thinks about protection against external influences for the metal, someone who wants to com...

Repair CVT "Nissan Murano": features and reviews

In the car «Nissan Murano” the breakdown of CVT is not uncommon. This type of transmission is installed in different models of modern cars. Periodically, you need to conduct maintenance, which if desired can perform wi...

Avtoodeyalo: reviews. Avtoodeyalo for the engine

the Need in the warming car engine can occur for different reasons. Most often, the insulation for engine compartment purchased to accelerate engine warm up in cold season, its the speed of the operating temperature. Owners review...

PCD – what is it? Transcript of marking autodeskew

When buying new footwear for your car many people faced with strange symbols on the rim of the disk. Standard parameters all understand: the radius of the wheels, the width of the profile, seasonality. But apart from them when buy...

How to improve the headlights?

For every motorist it is important that his vehicle was good and quality lighting. Without it is impossible to do in the dark or in conditions of poor visibility. But sometimes the light from the headlights is uneven or dim. Then ...

Comments (0)

This article has no comment, be the first!