Ultrasonic welding plastic, plastics, metals, polymeric materials, aluminium profiles. Ultrasonic welding: technology, harmful factors

Ultrasonic welding of metals is a process in which you get a permanent connection in the solid phase. The formation of juvenile plots (in which the formation of links) and the contact between them occurs under the influence of the special tool. It provides the combined effect of alternating the relative tangential displacement of small amplitude and the compressive normal force on the workpiece. We next consider in more detail what constitutes the technology of ultrasonic welding.

The connection Mechanism

Small-Amplitude displacements occur between the parts at an ultrasonic frequency. Due to these asperities on the surfaces undergo plastic deformation. Along with the connection zone evacuated pollution. Ultrasonic mechanical vibrations are transmitted to the area of the welding tool from the outer side of the workpiece. The whole process is organized in such a way as to prevent slippage of the fixture and a support for the surfaces of the parts. In the process of passing vibrations through the material dissipation of energy. This is provided by the external friction between the surfaces at the initial stage of welding and internal friction in the material located between the support and the tool after formation of the precinct setting. In connection with increased temperature, which facilitates deformation.

Behaviour

The Tangential displacements between the parts and the voltage that are caused by them and act together with compression forces from the welding provide the localization of intensive plastic deformation in small volumes in the subsurface layers. The whole process is accompanied by crushing and mechanical evacuation of oxide films and other contaminants. Ultrasonic welding reduces the yield strength, allowing easier plastic deformation.

Features

Ultrasonic welding promotes the formation of conditions necessary for the connection. This is due to the mechanical vibrations of the transducer. Thanks to the energy of vibration to create complex tension shear, compression and tension. Plastic deformation occurs by exceeding the limits of elasticity of the materials. Obtaining durable connection is achieved by increasing the area of direct contact after the evacuation of surface oxides, and adsorbed organic films.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

The Use of ULTRASONIC

Ultrasound is widely used in the scientific field. With the help of scientists explore a number of physical properties of substances and phenomena. In industry, ultrasound is used for degreasing and cleaning products, working with difficult to machine materials. In addition, the vibrations have a positive effect on crystallizing melts. Ultrasound provides them with the degassing and grain refinement, improving mechanical properties of cast materials. Fluctuations contribute to the relief of residual stresses. They are also widely used to speed up slow chemical reactions. Ultrasonic welding can be used for different purposes. Fluctuations can be a source of energy for the formation of seam and spot joints. Under the influence of ultrasound on welding the bathroom during crystallization improves the mechanical properties of joints by structure refinement of the joint and rapid removal of gases. Due to the fact that fluctuations actively remove dirt, artificial and natural film, you can connect parts with oxidized, lacquered and so the surface. Ultrasound helps to reduce or eliminate self-stresses that appear during welding. Due to fluctuations it is possible to stabilize the components of the connection structure. This, in turn, prevents the possibility of spontaneous deformation of the structures subsequently. Ultrasonic welding finds in recent years more and more widely used. This is due to the undoubted advantages of this method of connection compared to cold and contact methods. Very often used of ULTRASONIC vibrations in micro electronics.  is considered to be a Promising direction for ultrasonic welding of polymeric materials. Some of them it is impossible to connect any other method. Industrial plants are currently carried out by ultrasonic welding of thin-walled aluminium profiles, foil, wire. This is especially effective method for connecting products from heterogeneous raw materials. Ultrasonic welding of aluminium used in the production of household appliances. This method is effective in the splicing of sheet materials (Nickel, copper, alloys). Ultrasonic plastic welding has found application in the manufacture of devices of optics and fine mechanics. Currently developed and implemented in production machinery to connect diverse elements of the circuits. Fixtures are equipped with automatic devices, which significantly increases the performance.

is considered to be a Promising direction for ultrasonic welding of polymeric materials. Some of them it is impossible to connect any other method. Industrial plants are currently carried out by ultrasonic welding of thin-walled aluminium profiles, foil, wire. This is especially effective method for connecting products from heterogeneous raw materials. Ultrasonic welding of aluminium used in the production of household appliances. This method is effective in the splicing of sheet materials (Nickel, copper, alloys). Ultrasonic plastic welding has found application in the manufacture of devices of optics and fine mechanics. Currently developed and implemented in production machinery to connect diverse elements of the circuits. Fixtures are equipped with automatic devices, which significantly increases the performance.

The power of the UZ

Ultrasonic welding plastic ensures a permanent bond due to the joint action of high frequency mechanical vibrations and a relatively small compressive force. This method has manyin common with the cold way. The ULTRASONIC power that can be transferred through a medium will depend on the physical properties of the latter. By exceeding the limits of strength in the zones of compression, the solid material will collapse. In similar situations in liquids cavitation occurs, accompanied by the appearance of small bubbles and their subsequent collapse. Along with the latest process any local pressure. This phenomenon is used for cleaning and processing.

Device Nodes

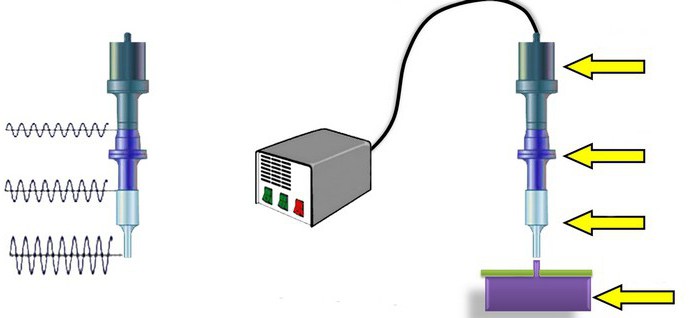

Ultrasonic welding of plastic is accomplished with the use of special machines. They contain the following nodes:

- Power Source.

- Oscillating mechanical system.

- Control Equipment.

- Drive pressure.

Vibrating system is used to convert electricity to mechanical for subsequent transfer to the site of connection of its concentration and obtain the desired value of the speed of the emitter. In this node is present:

- Electromechanical Converter with windings. It is enclosed in a metal housing and cooled by water.

- Transformer of elastic fluctuations.

- The Welding tip.

- Support with pressure mechanism.

The Fastening system is implemented with a diaphragm. The ultrasound radiation only occurs at the time of welding. The process occurs under the influence of fluctuations of the pressure applied at right angles to the surface, and the thermal effect.

Possibilities of the method

Ultrasonic welding is most effective for plastic raw material. Products from copper, Nickel, gold, silver, etc. can be connected with each other and with other low-plasticity products. With increasing hardness weldability by ultrasound is getting worse. Effectively connected with the ULTRASONIC refractory articles of tungsten, niobium, zirconium, tantalum, molybdenum. Ultrasonic welding of polymers is a relatively new way. These products can also be connected with each other and with other solid parts. As for metal, it can combine with glass, semiconductors, ceramics. Associate of the workpiece through the layer. For example, the steel products are welded together through the aluminum plastic. Due to the transient nature under high temperature obtained high-quality connection of dissimilar products. Properties of the raw material is subjected to minor changes. The absence of impurities – one of the advantages possessed by ultrasonic welding. Hazards for man are also missing. When connecting favorable hygienic conditions. Communication products are characterized by chemical homogeneity.

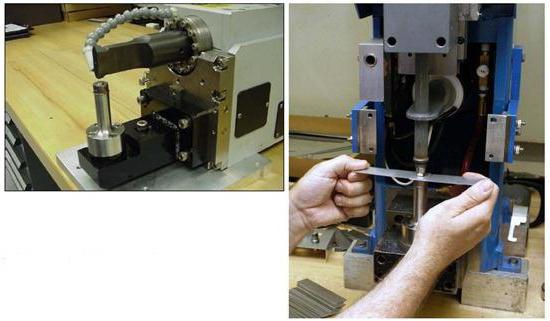

Connections

The welding of metal is carried out, as a rule, the lap method. This adds various structural design elements. Welding can be points (one or more), continuous seam or in circles. In some cases, when the preliminary molding of the workpiece end of the wire is t-connecting it with the plane. It is possible to carry out ultrasonic welding of several materials at the same time (package).

Thickness details

It is bounded by an upper limit. With increasing thickness of the metal blank is necessary to apply vibrations with greater amplitude. This will help to compensate for the loss of energy. The increase in the amplitude, in turn, is possible up to a certain limit. The restrictions associated with the probability of occurrence of fatigue cracks, large dents from the tool. In such cases, you should evaluate how suitable is ultrasonic welding. In practice, the method is used when the thickness of the products from the 3…4 µm to 05…1 mm. welding can be used for parts with a diameter of 0.01…05 mm. the Thickness of the second products may be significantly larger than the first.

Potential problems

When using the method of ultrasonic welding it is necessary to consider the probability of fatigue failure of the existing compounds in the products. During the procurement process can unfold relative to each other. As was said above, on the surface of the material from the tool are dents. The device itself has limited service life due to erosion of its working plane. In some points the material is welded to the tool. This leads to the wear device. Repair of equipment is accompanied by a number of difficulties. They are related to the fact that the tool itself acts as an element molded of a single structure node, the configuration and dimensions of which are calculated exactly at the operating frequency.

Preparation of instruments and the mode settings

Before performing ultrasonic welding of any complex events with the workpiece surface to carry out is not necessary. At desire it is possible to improve the stability of connection quality. It is advisable only to degrease the product with a solvent. To connect ductile metals, an optimum loop delay of the pulse relative to the start of the ultrasound. With a relatively high hardness of the product, it is advisable to wait for a small heating before turning on the BONDS.

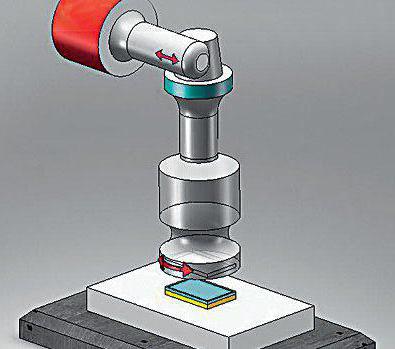

Circuit welding

There are several solutions.The technological scheme of ULTRASONIC welding differ according to the nature of the oscillations of the tool. They can be torsional, Flexural, longitudinal. Patterns are distinguished depending on the spatial position of the device relative to the surface of the weldment and method of transmitting compressive forces on the product and design features of the support element. For contour, seam and spot joints are used options with Flexural and longitudinal vibrations. Ultrasonic treatment can be combined with local pulsed heating of parts from the separate heat source. In this case, it is possible to achieve several advantages. In the first place it is possible to reduce the amplitude of the oscillations, and the force and the time of transmission. The energy properties of the thermal pulse and the period of its imposition on ultrasound act as additional parameters of the process.

Thermal effect

Ultrasonic welding is accompanied by a temperature rise in the wiring. The occurrence of heat is caused by the emergence of friction on the surfaces contacting the products, and also plastic deformation. They actually accompany the formation of a welded joint. The temperature in the contact area will depend on the strength parameters. Chief among them is the degree of hardness of the material. In addition, considerable importance is its thermal properties: thermal conductivity and specific heat. The temperature level affects the selected welding mode. As practice shows, appears a thermal effect does not act as the determining factor. This is because the maximum strength of the connections in the products is achieved before the temperature rises to an extreme level. To decrease the duration of transmission of ultrasonic vibrations it is possible, with a preliminary heating of the parts. This will also contribute to enhancing the strength of the joint.

Conclusion

Ultrasonic welding in the present in some industrial sectors is an indispensable method for joining parts. Especially popular is this method in microelectronics. ULTRASOUND allows you to connect a variety of plastic and hard materials. Today is actively conducted research work on improvement of tools and welding technology.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

JSC "Lytkarino optical glass factory": history, description, products

OJSC “Lytkarino optical glass factory” – leading Russian manufacturer of fiberglass products, optical glass, satellite lenses, astronomical mirrors, a variety of optical devices. Part of the holding «Schwab...

Mechanical engineering in Russia. Geography and structure

engineering in Russia is one of the most developed branches of industry and a very important component of the economy. Most of the largest companies in this sector were built during the Soviet period. According to available offici...

Retained earnings - it's easy!

the Goal of any economic activity is retained earnings. It is quite natural, because its presence means an increase in the equity capital of the company that allows you to make more and larger deals and, therefore, leads to increa...

Incubation of Turkey eggs is: temperature, timing

Turkeys are considered to be pretty good with the hens. However, to the young household this valuable the birds in large numbers is possible only under condition of cultivation with the use of the incubator. Modern models of such ...

Business model: the 8 points on the road to success

Many people want to start their own business, but few know how to start. To find investment? To write a business plan? To establish contacts with partners or to win the hearts of customers? What was missing in the first place? To ...

Addresses of the salons of "Beeline" in Moscow

One of the most popular network operator "Beeline" every day provides thousands of Muscovites mobile phones and the Internet. Company for more than twenty years, and is the only cellular communication that work even in such remote...

Comments (0)

This article has no comment, be the first!