Now - 21:43:27

The casting: technology, advantages and disadvantages

Using the lost wax casting models – a very popular method of casting production. The method is complex technological process and high labor costs in the preparatory processes. Therefore, it is used where it is necessary to accurately comply with the dimensions and ensure high surface quality parts. So cast turbine blades and high-performance tool, dentures and jewelry, and sculpture of the complex configuration. The essence of investment casting is that the mold for casting is all-in-one model of the fusible material during molding is not removed, and is smelted. This ensures careful adherence to size and topography. In the rest of the model cavity and the metal poured into it. At the end of the cooling form is destroyed and the product is removed. When casting large series, the cost of products is reduced.

Advantages

The Main advantage of casting - accuracy of transmission of shape and low surface roughness. In addition, the presence of other advantages:

- Available for the production of parts made of alloys, is hardly affected by mechanical processing.

- Reduces the need for further mechanical processing.

- Molded products, which by other methods would have to produce parts and to assemble.

- In a large series of reduced labour intensity (per one product) and its cost.

- The Possibility of mechanization and partial automation of preparatory operations of the casting.

These advantages of the push method is among the most popular and used in today's metallurgy, especially in combination with modern progressive methods of casting.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Disadvantages of investment casting

The Undoubted advantages of the method, it would seem, was to ensure its dominance among other ways. However, despite the popularity of the method of casting, the shortcomings constrain its wide distribution. The main drawback is the complexity of the multi-stage process. It requires a rather complicated and costly processing equipment for the preparatory stages. For simple products produced in small series, this method has a higher cost.

For cost-effective application of investment casting advantages and disadvantages are compared, the decision on its selection is made based on the evaluation of the ratio price/quality. Therefore, it is used mainly for the most important and expensive products that are difficult to obtain by another method, such as turbine blades, sculptures, high-speed tools, etc. Another area of application - high-volume castings, which allows economies of scale to achieve significant cost reduction.

Technology

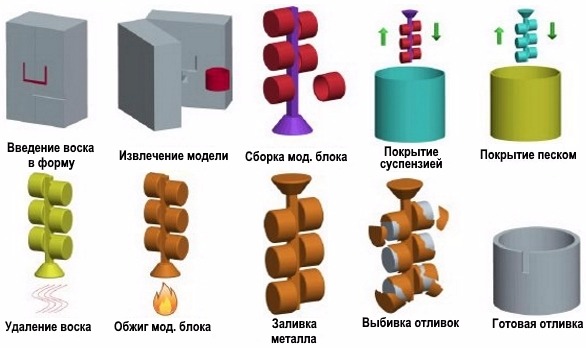

The Technology of investment casting is a multi - stage production process, which has a relatively high complexity. At the first stage perform the master-model, it will become a benchmark for manufacturing working models, and after going through all the stages of the final product. For the production of the master model is used as a special model formulations, and traditional plaster or wood. The material of the master model needs to combine strength and ease of processing.

The technology of investment casting involves creating a mold that will cast all working models. Molds are made from plaster, rubber, silicone, rarely from metal. Structurally, it must be detachable and is designed for repeated use. The mold fill modeling composition, after curing it apart and remove another working model.

In the production of unique items or short runs, the steps of creating the master layout and mold flow, and layout (or several) are doing, by molding the material manually.

The Next stage of the process of investment casting - the production around the layout (block layout) molding shape. These matrices are structurally already sealed and disposable, that allows to achieve the careful observance of the dimensions and roughness of the product. In modern industry there are two types of forms - traditional sandy-clay for casting in the ground and shell molds for the production of precise and expensive parts.

After completing the form, the layout of it melted by heating or purging with superheated steam. Shell molds are additionally strengthened by heating to 1000 C.

In the final stage of the process is actually fill product cooling in natural conditions or in a special manner in the thermostat, the destruction of forms and cleaning products. The method allows to obtain high-quality castings weighing from a few grams to tens of kilograms.

Model trains

Material for the production layout needs to have certain properties. It needs to have properties such as:

- Plasticity in the solid phase. To enable accurate repetition of the shape of the future product and correct it if necessary.

- Strength. The model must be able to withstand without deformation the process of forming a shape around it.

- Fusible. The rendering model is notshould require a large investment of time and energy.

- Fluidity in the molten state. The composition must be easily penetrate into all cavities and parts of the relief, exactly repeating the shape of the future details.

- Efficiency. Particularly important for the production of large series.

For model compounds are usually used a mixture of stearin and paraffin. These materials complement the parameters of each other, compensating for the lack of the melting point of paraffin and the excess viscosity of stearin.

Equally popular in the industry are formulations based on lignite wax. Its main properties are moisture resistance, strength and the ability to form a very smooth coating, which is especially valuable for modeling products.

Are also Used compounds consisting of a mixture of brown coal wax, paraffin and stearin.

Consulting

For the production of a unique product layout, prepare, cut out a piece of model material manually or by templates. Models having the form of bodies of rotation, are also produced on lathes. Lately increasingly common method of 3D printing models. It is suitable for both single models and small series.

The Cost of a modern industrial 3D printer is still high, however, due to the ease of switching from one product to another it can become an effective tool for making models in the case of a large number of heterogeneous orders in small series.

To manufacture a large number of identical layouts, the matrix is made from gypsum, rubber, silicone, or metal. Working models are produced, in turn, by casting into the matrix. By design, the mold must be collapsible, to be able to produce a given quantity of models. The selected material should also provide the opportunity to meet such requirements as strength, density, low roughness, chemical inertness in relation to the layout. The substance of the mold must also have a minimum adhesion to layout to ensure ease of retrieval of ready-made layouts and compliance dimensions. An important property of mold - its strength and durability, especially for large series.

The Production of models and units

Widespread method of making wax models, casting them under a low pressure in mold. The injection of a liquid mixture is produced manually, with reciprocating syringe, or mechanical, hydraulic or pneumatic blowers. In the case of lignite wax required to preheat the feed pipes of the composition because of its high viscosity. Layouts of foamed polystyrene made by extrusion molding on automated units.

To improve economic efficiency and reduce the complexity in the case of serial production of small castings of their models combined in blocks. Over the blocks form the Gating system, adding a separate layouts to the sprues by means of manual soldering iron. In the case of a single casting or small series models are made manually.

When shaping Gating systems require turbulent melt flow, uniform filling of all of the elements of the matrix. When the gasket forms from PGS also need to follow a uniform filling of all openings between the runner and prevent them from damage.

Production

In this method of casting is found in two basic forms:

- Sand-clay mixtures (ASG).

- Shell.

Forms for casting of PGS is used mostly in the production of small series of products, which do not require very high precision. The manufacturing process is labor intensive and requires a high, and often uniquely qualified modellers and moulders. Partial mechanization can only be single transactions, such as cooking and filling the molding mixture, its compaction.

The Shell molds, in contrast, are used for the production of parts requiring precision manufacturing. Their manufacturing process more complex and lengthy, but better amenable to mechanization.

Casting in the ground

This is the early mankind developed the method of processing metals. It was mastered by our ancestors, simultaneously with the introduction of metal products as weapons, instruments or utensils, or about 5 thousand years ago. Cast the molten metal into the prepared matrix mixture of sand and clay. The earliest places of processing of metals was any where close located deposits of metals in the form of nuggets and alluvial deposits. A typical example is internationally known for its cast iron lace cast Kasli factory in the Urals.

Method of investment casting is used for the manufacture of metal products - ferrous and non-ferrous. And only for metals exhibiting increased susceptibility to reactions in the liquid phase (such as titanium), necessary to do a matrix of the other compositions.

The Production process of casting in PGS consists of the following phases:

The- Manufacturer model;

- Preparation of the flask;

- Backfilling and compaction of the mixture in the flask;

- Metal casting;

- Removing and cleaning the casting.

Form of PGS - single use. To get the finished product, it will break. At the same time, most of the compounds available for secondary use.

The materials used for the PGS consists of predominantly quartz sand with different grain size and plastic clays, the content of which ranges from 3 to 45 percent. For example, ornamental castings are produced using a mixture with 10-20% clay content, especially for large castings, the clay content was adjusted to 25 %.

Apply two subspecies:

- Lining mixture. Located on the inner surface of the form and interact with the molten metal. Needs to be heat resistant, capable to withstand temperature differences and resulting tensions. Such mixtures of small grain to thoroughly communicate the details of the surface. Is very important and the ability of a mixture to getproposal.

- Filling mixture. Used for backfill between the facing layer and the walls of the flask. Needs to withstand the weight of poured metal to keep its shape and to facilitate the timely and complete removal of gases. Are made from cheaper grades of sand will be reused.

If the injection gases are released not through the mass of sand, and through a Gating system, casting defects occur, leading to marriage.

The Traditional technology of casting in earth details illustrated in the tape Tarkovsky "Andrei Rublev". In the Novella “Bell” the boy Boriska, the son of the deceased master, the plot heads artel foundry molds and Church bell.

Casting in shell molds

Method of casting in shell shapes investment casting is characterized by the best transfer of product size and low surface roughness. The model was made of low-melting compounds, such as lignite wax. In the foundries also used the composition of the paraffin-stearin in equal shares. In the case of castings of large dimensions in the model material include salt keeps the model from deformation. By immersing in a solution of the model is covered in 6-10 layers by high temperature suspension.

Hydrolyzed Binder are silicates, as the heat-resistant sprinkles take crystals of corundum or quartz. Materials for the production of shell molds feature high strength, low hygroscopicity and excellent permeability.

The Layout is dried in an atmosphere of gaseous ammonia. In the next step the form is heated to 120 C to remove paraffin model. Remnants of the mixture is removed by superheated steam under great pressure. Further, the shape is calcined at a temperature up to 1000 C, which leads to its final consolidation and removal of agents, able to stand out in the form of gases during the casting.

The Shell is placed in the similarity of the flask, which poured steel shot. This helps to save the configuration when filling forms melt and simultaneously improves the conditions of cooling of the casting. The pouring of the melt takes place in a preheated 1000 forms. After cooling the product at a special program in the thermostat form destroy, remove and clean the casting.

The Main advantage of this casting method is high precision transmission product size and low surface roughness.

Additional advantages of the method:

- The Casting of parts from alloys that are difficult mechanical processing.

- Casting products, which otherwise have to be cast in parts and then piece together.

The Disadvantages of this method of casting – small coefficient of metal use and increased complexity.

Precision casting

Precision casting investment casting - the so-called technology and the end products. High precision molding is possible because in the process of preparation forms no need to extract from it the layout of the product. When using the traditional method of manufacture of matrices for the casting – a complex and tedious multistep process. This is especially true in the case of casting parts of complex configuration, with recesses, cavities and internal voids.

For Example, when casting cast iron or copper vases that have variable curvature of the surface, we have to apply a lot of tweaks. So, first fill the lower half of the flask, then the model is taken, turn over and pour the top half. The model has to do composite handles vase is made of two elements, pull them out using the cavity model in two steps - first the bottom element, and then the top. All these many turning and pulling can't be positive of the integrity of the surface of the mold and ultimately on the accuracy of the size of the casting and surface quality. In addition, there is the problem of precise alignment of the parts of the flasks and reliable fastening them to each other.

Manufacturer of investment casting is devoid of these shortcomings, it does not require such a high qualification modellers and significantly reduces the labor preparatory to molding operations. This is especially true for large runs of castings.

Method allowsto achieve the 2-5-th class of accuracy as per GOST 26645-85. This allows you to cast these high-precision products like turbine blades, cutting tools, including high performance mills and drills, heavy loaded high-duty brackets, small highly loaded parts of vehicles, machines and other complex mechanisms.

The High accuracy of dimensions and surface grade to minimize the need for further machining of the casting, thus saving metal and reduce the cost of production.

Hardware

The Equipment for casting requires diverse and complex. The enterprises combine them into a single and cohesive complex, organized as a of area, Department or individual production.

The complex depends on the scale of production, size, configuration and quantity of castings.

Thus, in the manufacture of dental prostheses and jewelry, the equipment will include:

- Model table

- Muffle furnace with thermostat control;

- A set of scalpels and spatulas to correct the shape of the model;

- Molding Board;

- Flask;

- Containers for the storage and preparation of sand mixture;

- A set of tools for ramming the sand mix;

- Crucible for melting metal;

- Pliers;

- A hammer to break form.

This industrial complex will easily fit on one table and one cupboard. If you plan mass production, for example, aluminum casting parts of any device, you will need equipment for:

- Forming and pouring ceramic molds;

- Drying forms;

- Melting of the model material and applying heat-resistant layer;

- Cleaning of castings from the moulding material.

And finally the actual equipment of the foundry designed to produce the melt and pouring it into the form. This can be the equipment for casting:

- Low pressure;

- Centrifugal;

- Conventional gravity method.

Installation for pressure casting and centrifugal casting are separate highly mechanized and automated production complex that is isolated from the atmosphere of the shop. They minimized manual labour and finding a person in harmful conditions. Sealed chamber in which the systems provides full capture and flue gas cleaning, which significantly increases the environmental friendliness of the company.

The Casting has a high potential for development, especially in combination with progressive methods of making and methods of casting.

Article in other languages:

AR: https://tostpost.com/ar/business/9050-the-casting-technology-advantages-and-disadvantages.html

HI: https://tostpost.com/hi/business/9054-the-casting-technology-advantages-and-disadvantages.html

JA: https://tostpost.com/ja/business/9054-the-casting-technology-advantages-and-disadvantages.html

PL: https://tostpost.com/pl/biznes/16187-odlewania-technologia-zalety-i-wady.html

ZH: https://tostpost.com/zh/business/9855-the-casting-technology-advantages-and-disadvantages.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

a Good harvest it is possible to fall only if carried out the right selection of tubers and made to prepare potatoes for planting in the spring. When I can get on the germination from the cellar seed tubers depends on their method...

Public baths in Khimki: description and address

There are people who loved this holiday as a trip to the baths. Not surprisingly, because it is communicating with friends, companions, and useful procedure. Public baths in Khimki will help to experience a real Russian sauna, whi...

Abrasive materials are characterized by their ability effective mechanical action. With their help, remove dirt, remove raids, produce clean surfaces of rust and paint. Work item, in fact, are abrasive granules, which can have dif...

Assessment of efficiency of investment projects is important

the level of profitability of activity of the enterprise is affected by how quickly and correctly the entrepreneur is able to make decisions regarding the investment of available funds. It is therefore important to assess the effe...

Paul Will tattoo with kids and not only

Paul Will tattoo which often is the interest of the fans – a well-known entertainer. Also special attention is paid to his relationship with Laysan Utyasheva. Pair twice new parents about what a celebrity does not get tired ...

What schedules are for enterprises?

What are the work schedules in the enterprise or in the company? This question asks every person that wants to optimize their working activity because of certain reasons. The article will answer the question.General informationthe...

Comments (0)

This article has no comment, be the first!