Now - 08:57:11

Synthetic fibers. Synthetic polyamide fiber

Synthetic fibers began to be produced industrially in 1938. At the moment, there are already a few dozen types. All these have in common is that the starting material serve low-molecular compounds into the polymers by chemical synthesis. Dissolving or melting of the obtained polymers is the preparation of the molding or spinning solution. They are molded from a solution or melt, and then subjected to the finish.

Varieties

Depending on the features that characterize the structure of macromolecules, synthetic fibers are subdivided into hetero-and carbon-chain. The former include those derived from polymers whose macromolecules in addition to carbon, are present and additional elements-nitrogen, sulphur, oxygen and others. These include polyester, polyurethane, polyamide and polyurea. Carbon-chain synthetic fibers are characterized by the fact that the main chain they have built of carbon atoms. This group includes PVC, polyacrylonitrile, polyolefin, and fluorine-containing polyvinylsilane.

The Polymers that serve as the basis for the production of heterochain fibers are obtained by polycondensation, and the product is molded from melts. Carbon-chain are obtained by chain polymerization, and the formation usually occurs from solutions, in rare cases, from melts. You can consider any one of the synthetic polyamide fiber, which was called siblon.

Creating and applying

A word like siblon, for many is completely unknown, but earlier on the labels of clothes you can see the abbreviation for VVM, which hides viscose high modulus fiber. Then the producers thought that the name would look nicer than siblon, which could be associated with nylon, and capron. The production of synthetic fibers of this type is made from trees, fabulously as if it didn't look.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Features

There was siblon in the early 70-ies of the last century. It is an improved viscose. The first stage is getting the wood pulp, it is isolated in pure form. The largest quantity is contained in cotton – about 98%, but from fibers of both cotton and without this make a great thread. Therefore, for the production of cellulose is more commonly used timber, in particular conifers, where it contains 40-50% and the rest – unnecessary components. They are required to get rid of in the process of production of synthetic fibers.

Process creation

Synthetic fiber produced in stages. The first stage is the process of cooking, during which the wood chips all extra substances are moved in the solution, and is the breakdown the long polymer chains into smaller pieces. Of course, there is not complete only with hot water, supplements are made of different reagents: natanov and others. Only cooking with the addition of sulphates allows to obtain pulp that is suitable for the production of siblon, as it has less impurities.

When the pulp is already digested, it is sent to bleaching, drying and pressing, and then move to where it is needed – the manufacture of paper, cellophane, cardboard and fibers, i.e. primary production. What do you think happens next?

Post processing

If you want to synthetic and natural fibers, you must first prepare a spinning solution. Cellulose is a solid substance which is difficult to dissolve. Therefore, it is usually converted into water-soluble ether diarioporno acid. The process of making this substance is quite long. First is the treatment of pulp with hot alkali followed by squeezing, the solution is moving unnecessary items. After pressing, the mass is crushed and then placed in a special chamber, where prednisilone – there is a shortening of the cellulose molecules by almost half due to oxidative degradation. Further there is the reaction of alkali cellulose with carbon disulphide, which allows to obtain a xanthate. A mass of orange color, similar to dough, the air diarioporno acid and a basic substance. This solution for viscosity called "viscose".

Next is the filtration to remove the last impurities. Dissolved air is released through a “boiling” of the ether in vacuum. All of these operations lead to the fact that the xanthate is like a young honey-yellow and stringy. This spinning solution is ready.

Getting fiber

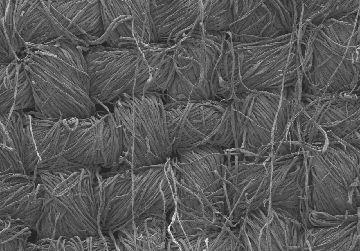

The Solution is pressed through a Spinneret. Artificial synthetic fibers not just predetsya the traditional way. This operation is difficult to compare with the simple textile is more correct to say that it is a chemical process that allows millions of streams of liquid become solid viscose fibers. On-siteRussia cellulose obtained by the viscose and siblon. The second type of fiber and a half times stronger than the first, is characterized by greater resistance to alkali, fabrics of different hygroscopic, less shrinkage and wrinkling. But differences in manufacturing processes of viscose and siblon appear in the moment when in the precipitation bath after the dyes are just "peoples" of synthetic fibers.

Chemistry help

To obtain the viscose in a bath filled with sulfuric acid. It is intended for the decomposition of the ether to produce pure cellulose fibers. If you need the siblon add to the bath zinc sulphate, partially providing a barrier to hydrolysis of the ether, so the threads will contain the residual xanthate. And what it gives? Next, the fibers are subjected to stretching and form. When polymer fibers are remnants of the xanthate to pull the cellulose polymer chains along the fiber axis, and not to place them chaotic, which is typical for conventional viscose. After drawing bundle of fibers is cut into spacelike a length of 2-10 millimeters. After a few more treatments is pressing fiber into bales. Tons of wood sufficient to produce 500 kg of pulp, which will be released 400 pounds of fiber siblon. Spinning of cellulose is carried out approximately two days.

What's next do with siblon?

In the eighties, these synthetic fibers are used as additives to cotton to yarn was spun by better and not torn. From siblon was doing a substrate for artificial leather, and also used it in the manufacture of asbestos products. Then the technologists were not interested in creating something new, it required more fiber to implement the plan.

And in the West in those days, high modulus viscose fiber were used for the production of fabrics, which were low cost and durability in comparison with cotton, but absorbent and breathe. Now Russia did not have its own cotton regions, so siblon hopes. Only demand while not particularly great, as the fabrics and domestically produced clothing is now almost no one buys.

Polymer fibers

They are usually divided into natural, synthetic and artificial. Natural the fiber, the formation of which is carried out in natural conditions. They are usually classified by origin, which determines their chemical composition, animal and vegetable. The first consists of a protein, namely carotene. This silk and wool. The second consists of cellulose, lignin and hemicellulose.

Artificial synthetic fibers are obtained by chemical processing of polymers existing in nature. They decided to include acetate, viscose, alginate and protein fibers. As raw materials for their preparation, to serve as a sulphate or sulphite wood pulp. The production of artificial fibres in the form of textile and cord yarns and staple fiber, which is processed together with other fibers in the production process of different tissues.

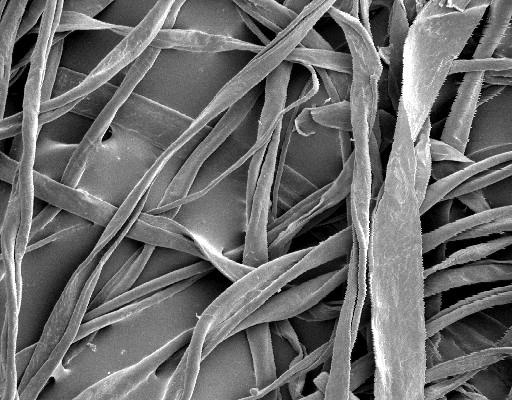

Synthetic polyamide fiber obtained from polymers derived artificially. The feedstock in this process uses polymeric fibers formed from flexible macromolecules weakly ramified or linear structure, with significant ground – more than 15,000 atomic mass units, and a very narrow molecular weight distribution. Depending on the type of synthetic fibre is able to have a high degree of durability, are of significant size relative elongation, elasticity, resistance to multiple loadings, low residual deformation and rapid recovery after removal of the load. Therefore, apart from use in textiles, they found application as a reinforcing elements during the manufacture of composites, and all this helped to make the special properties of synthetic fibres.

Conclusion

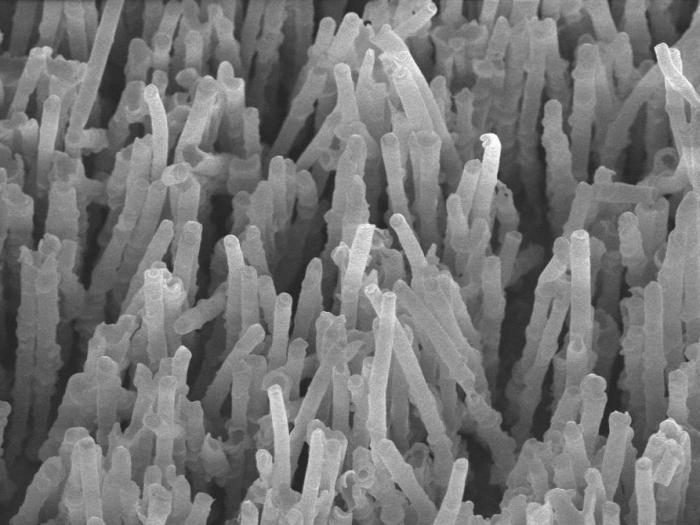

In the last few years we have seen very steady growth in the number achievements in the development of new polymeric fibers, particularly para-aramid, polyethylene, heat-resistant, combined, the structure of which – core-shell, heterocyclic polymers, which include different particles, for example, silver or other metals. Now nylon material – this is not the height of engineering, since there is now a huge amount of new fiber.

Article in other languages:

AR: https://tostpost.com/ar/business/8127-synthetic-fibers-synthetic-polyamide-fiber.html

BE: https://tostpost.com/be/b-znes/14190-s-ntetychnyya-valakna-s-ntetychnae-pol-am-dnae-valakno.html

DE: https://tostpost.com/de/business/14048-synthetische-fasern-synthetische-polyamid-faser.html

ES: https://tostpost.com/es/negocio/14021-las-fibras-sint-ticas-luminescent-fibra-sint-tica.html

HI: https://tostpost.com/hi/business/8008-synthetic-fibers-synthetic-polyamide-fiber.html

JA: https://tostpost.com/ja/business/8052-synthetic-fibers-synthetic-polyamide-fiber.html

KK: https://tostpost.com/kk/biznes/14192-sintetikaly-talshy-tar-sintetikaly-poliamid-talshy-y.html

PL: https://tostpost.com/pl/biznes/14583-w-kna-syntetyczne-syntetyczny-fiber-wiec-cy.html

PT: https://tostpost.com/pt/neg-cios/14482-as-fibras-sint-ticas-sint-tico-de-fibra-luminescente.html

TR: https://tostpost.com/tr/business/14201-sentetik-lif-sentetik-luminescent-fiber.html

UK: https://tostpost.com/uk/b-znes/14327-sintetichn-volokna-sintetichne-volokno-pol-am-dne.html

ZH: https://tostpost.com/zh/business/1300-synthetic-fibers-synthetic-polyamide-fiber.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Vladimir chemical plant history, description, products

JSC «Vladimir chemical plant” is a large chemical enterprise, located in the city of Vladimir. Production is focused on the manufacture of PVC cables, vinyl plastic, granular or rigid sheet materials. The collective wa...

Andrey Kozitsyn: biography, photos

He is a successful businessman and experienced Manager, visionary and Manager. Thanks to these qualities, the entrepreneur Andrey Kozitsyn and was able to turn into a wealthy man, the financial assets which, according to the magaz...

Thermal power plant: description, operation and specifications

the Station energy security operate today in different variations. Power plants working on thermal energy are not the most common, but they have a lot of attractive qualities from the point of view of applications. This type of eq...

Chinese goods in the "Taobao": customer reviews

“Taobao” – Chinese Internet-shop that is created for the end user. The system functions on the C2C Protocol. What is it? This is a special form of electronic Commerce that involves the sale of products and provis...

Many wonder: “I Want to start my business but where to start?» Understanding that this business takes a lot of time and effort, people leave this pipe dream. It is much easier to work 8 hours, come home, watch TV, scor...

Contract with PI for the provision of services: sample. The content of the contract, terms

Every business transaction begins with the development of a formal agreement, making him a key and controversial elements, determining economic benefits. Signing a contract with PI for the provision of services, a sample of which ...

Comments (0)

This article has no comment, be the first!