The Shewhart-Deming cycle: the stages of the production management

Management is committed to produce effective production management and product quality. There are several approaches to solving this problem. Introducing the authors of the theory of continuous process improvement Walter Shewhart and William Deming, a management cycle which are known worldwide. They suggest that, despite the large difference in the production procedure for all systems are the same. Will tell you about what the essence of this theory and how this model is applied in practice.

The Concept of production management

The Organization of any process, the impact on different objects called management. Management processes are found not only in the workplace, each person has to organize their lives, make a variety of decisions to achieve goals. Therefore, the management – it's such a broad scope, which is far beyond the scope of creating products or services. The idea of William Deming, a management cycle which we consider, is that management exists in almost all areas of human activity, and they have a total order of actions. Any office connected with the collection and processing of information, decision-making, coordination processes, prediction, control and assessment of effectiveness. Modern management considers many processes, including production, projects. And an essential attribute of any project is quality. In this connection, there is such a specific area as quality management.

The Basic principle of quality management

In any field of production, today introduced the quality management system in compliance with international standards. They are aimed at ensuring stable quality of the produced goods or provided services. The quality management is based on several basic principles. These include customer orientation and their needs, involvement and motivation of employees, the adoption of realistic decisions based on facts, the lead Director and the continuous improvement of quality. It is about the implementation of the latter principle and thinking of the researchers who created the Deming cycle and the Shewhart. Quality improvement is a permanent objective of every organization. It covers all levels of businesses ranging from individuals to the Manager, production environment and end product. To improve the quality of can use one of two methods: breakthrough and incremental. It is achieved through standardization, analysis and measurements, as well as optimization and rationalization.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

The Concept of Suharto

American management consultant, the famous scientist Walter Shewhart in the 1930s explores the issues of quality management of industrial products. His work on the control maps, which are the means of fixing the observation of the stability and predictability of any process, became a serious stage in development management. For many years he collected statistics on control of industrial processes. And the peak of his scientific work was the management cycle of Deming-Shewhart. In his books he proves the statistical method of consistent quality control of production processes and end products. In the management of Shewhart identifies three main phases: development of technical tasks and specifications for the release of future products, manufacturing according to specification, checking product quality and its compliance with the specified parameters. Later, this scheme transforms the scientist into a model of 4 steps:

- The Design of the product.

- Product Manufacturer and tested in the laboratory.

- Release the product to market.

- Validation of the product in action, consumers ' appraisal.

W. Shewhart put forward the process-based method as the most productive in management. His ideas had an enormous influence on the development of control theory.

The Concept of Deming's

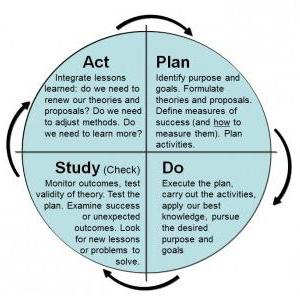

Student W. Shewhart and William Edwards Deming took to Refine and improve his theory. He was the Creator of the concept and General organizational method of total quality management. Deming explained the point of view that the company is improving the quality associated with improvement in three areas: production, personnel and products. Also, the result of years of research there was a system of Total Quality Management, which is associated primarily with the work of Deming. The cycle of quality improvement, according to the scientist, has no end, and has a circular character. He has identified two basic mechanisms for business improvement: quality assurance (improvement of production, training of staff, etc.) and improving quality. According to the scientist, is not enough to maintain a decent level of quality, you need to constantly strive to improve his level. Updated the Deming cycle includes the steps of a different nature. Is: planning, implementation, checking and action. Discuss the characteristics of each stage in more detail.

Planning

In the first cycle the Shewhart-Deming includes such important stage, as the product development and manufacturing engineering. According toresearchers, entrepreneurs must plan the improvement of our products. And for this to set new goals, evaluate the resources to create the best plan of action, appoint executors and deadlines. At this stage it is important to find problems and ways of their solution. To detect the improvement, you must carefully analyze the situation, production process, market. Analytical actions will help to detect potential for improvement. Also at this stage detailed plans for improvement, is the strategy of production. A quality plan allows us to foresee the force majeure and to lay a solid Foundation for business.

Implementation

The plan – an important part of management. The Deming cycle involves the allocation in a separate phase quality management phase “execution”. At this stage, Deming recommends that you first start with conceived on a small scale to prevent large-scale losses in case of failure. When implementing plans it is important to follow the developed guidelines and specifications. The Manager must closely monitor the actions at each technological step, to comply with all requirements. In the concept of Deming this stage is more of a testing stage, testing, rather than serial production. The launch of a series does not require such close attention of the head, but the first launches – is extremely important. The Manager must be 100% convinced that all technologies are observed, it is a guarantee of quality.

Validation

After launching mass production, the researchers recommend to conduct a diagnostic study. The Deming cycle includes a large analytical phase in which it is necessary to evaluate the process, to try to find new potential for quality improvement. It is also necessary to evaluate the features of perception of a product or service by the consumer. For this test, focus groups, analysis of customer reviews. Also at this stage be sure to perform the diagnostics of processes, their compliance with technological standards. In addition, passes the assessment of performance of staff, monitoring of staff performance and produce key performance indicators (KPIs). If it finds any deviations from specified parameters, then the search for the causes of this.

Actions

The Last stage of the Deming cycle – the elimination of discovered infringements and shortcomings. At this stage we are taking all possible actions to obtain the planned quality of the product. Also performed documentation and written consolidation of the obtained results in the form of specifications and instructions. The Deming cycle, the stages of which are associated with various stages of quality control assumes a circular motion. So after all the flaws and points of possible quality loss is resolved, you should again go back to the first level and start to seek new opportunities for improvement. The experience cycle is necessarily used on the following round, it helps to minimize costs and improve product quality.

The Key principles of Deming's

Decoding his theory, the scientist formulates a number of postulates which has received the name of “Principles of Deming”. The cycle of quality improvement is based on them and comes from them. The most important principles are the following:

the Constancy of purpose. Quality improvement as the dominant objective must consistently be achieved in the framework of the strategy and tactics.

- the Head is personally responsible for quality.

- quality Control should not be mass, it needs to be built into the production system.

- the Rules and objectives must be carefully justified and realistic.

- encourage commitment of staff to education, to motivate employees to improve their skills.

- Improvement of quality must become a part of the mission and philosophy of the company, and all his adherents should be the managers.

- Staff should be able to be proud of the results of their labor.

Subsequently, on the basis of these postulates were formulated the main principles of international quality system.

Application cycle the Shewhart-Deming

A model of the Deming-Shewhart received the name of “the PDCA cycle”, is widely used in modern practice of management. The Deming cycle, an example of which can be found in the organization of work of almost all major global corporations, is a recognized tool to improve the quality of the products. Most fully and consistently, the concept has been perceived in Japanese management. In this country, Deming was perceived as a national hero, he has received several awards, including from the hands of the Emperor. Also in Japan established an award named after Deming. In the early 21st century the concept has been actively used in the Russian management, it is the basis for the development of international and domestic quality standards.

Article in other languages:

BE: https://tostpost.com/be/b-znes/39462-shuharta-dem-ng-cykl-etapy-k-ravannya-vytvorchascyu.html

DE: https://tostpost.com/de/business/38969-shewhart-deming-zyklus-phasen-produktionsmanagement.html

HI: https://tostpost.com/hi/business/23565-shewhart.html

JA: https://tostpost.com/ja/business/21557-shewhart-pdca.html

KK: https://tostpost.com/kk/biznes/39843-shuharta-deminga-cikl-keze-der-nd-r-st-bas-aru.html

PL: https://tostpost.com/pl/biznes/41597-shewharta-deminga-cykl-etapy-zarz-dzania-produkcj.html

TR: https://tostpost.com/tr/business/36404-shewhart-deming-d-ng-s-a-amalar-retim-y-netimi.html

UK: https://tostpost.com/uk/b-znes/40295-shuharta-dem-nga-cikl-etapi-upravl-nnya-virobnictvom.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

United company RUSAL: structure, management, products

RUSAL Corporation or «RUSAL» is one of the largest Russian private companies. The Corporation also actively cooperates with partners from the countries of near and far abroad and is one of the most powerful players of ...

Payroll of the employees. Security human resources

the Study of the structure of the state and assessment of labour potential of the enterprise — the most important task of his leadership and responsible professionals. Through its solutions can be applied to methods involvin...

The market is Rich, Saint Petersburg, Russia: description and interesting facts

Petersburg is resplendent architecture and mysteries. Historical places in the city are not considered – pompous palaces secret coups, and amorous passions. Avenues and streets remember the cobblestones raced as crew or on t...

How to open handcuffs without a key? Secrets of hacking of handcuffs

Before reading a fascinating and least useful of the story you need to define the following: if you for some reason fell into the hands of the police, completely eradicate the thoughts on how to open handcuffs without a key, becau...

Kanban - what is it? The principle of lean production

Kanban – what is it? Very interesting information contains the card is Kanban, and how the method performs in the production? In the article, we will explain the rules of effective use of Kanban, and give a vivid description...

for a long time all over the world used convenient way to move goods. Currently, there are a large number of different capacities for transportation, small and large. Types of containers, as they are called, are different, they ar...

Comments (0)

This article has no comment, be the first!