Now - 08:54:05

Hot-dip galvanizing. The process of galvanizing metal products

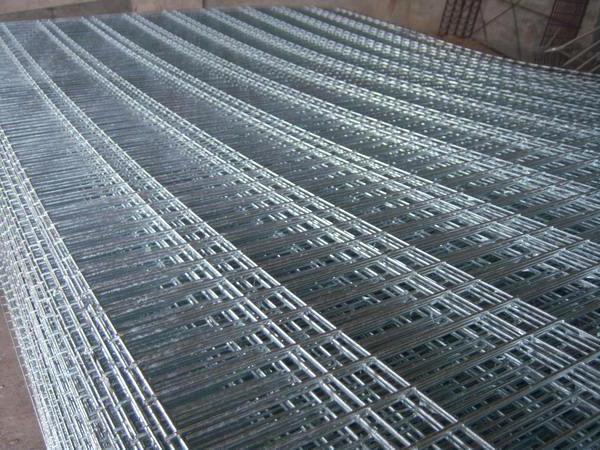

In the construction sector and industry, we observe a transition from metallic materials to high strength plastics and advanced composites. This is due to the fact that synthetic substitutes are close in characteristics to steel alloys, but they are spared the disadvantages of metal, one of which is corrosion. At the same time a complete rejection of the traditional material can not in all industries, therefore remain relevant and means to remove the rusts. One of the most popular techniques of this type is a hot-dip galvanizing, which forms on the surface of the product is durable and reliable protective layer.

The Principle of protection by galvanization

After passing a series of preparatory treatments of the product or a design are applied with molten zinc. This is usually done by dipping the workpiece into a liquid mass so that filled all the pores of the metal structure. There are some things you should consider before performing hot-dip galvanizing. Technology suggests that the high anagnost of zinc relative to the base metal will contribute to the self-absorption of zinc in the structure of the material is already in the process of operation. The speed of the filling uncovered plots is on average 2 mm per year.

However, the place with threads and nuts may become sources of corrosion development. To prevent such processes is possible by means of the original use of hardware protection against rust. This is particularly important if it is hot-dip galvanized, bolts which have a high power load.

Preparing for surgery

In the preparation phase the main task is to clean the surfaces and to ensure the potential homogeneity in the reactions of zinc and iron when immersed in a container of the active mass. This is achieved by several processing steps, including degreasing and rinsing. Later followed by operation of etching and glosowanie. Degreasing is to remove particles of dirt and oils – this will depend on the efficiency of penetration of zinc in the structure of the metal.

As a rule, this operation is carried out by degreasing agents, in order to obtain high-quality hot-dip galvanizing. Technology implementation is realized rinsing after degreasing. At this stage it is important to remove all excess material has been used in removing the surfaces of traces of oil. In particular, the foam is removed from the solutions and reagents that dissolve the chemicals.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Etching billets

This procedure can also be attributed to the stages of purification of the metal surface. But if in the previous cases, the material dumped from the attacks of dirt and oil, this time will have to deal with mill scale formed during heat treatment. In the etching process uses hydrochloric acid, the chemical action which allows you to not just clean, but also shiny surface. Almost every hot dip galvanizing plant develops its own unique recipes of active media, which in different proportions can include inhibitors to eliminate the hydroxyls and oxides. The observance of precise proportions needed for the reason that in addition to scale these solutions also affect the structure. Therefore, engineers seek to limit excessive action of the chemicals on the metal, preventing and risks of hydrogen saturation.

Fluxing

In the process of glosowanie performs several tasks. Chief among them is the completion of preparation of metal surface to the basic procedures galvanizing. In particular there is a dissolution of oxides that can be re-formed during rinsing. In addition, the fluxing protects the material due to the passivated film. The coating in some way begins to create a protective base that will continue hot-dip galvanizing of metal, and in particular its internal structure. But if the zinc is to protect the material from external influences in the process of its use, the passivated layer prevents oxidation in the framework of the galvanizing, and at the same time increases the wettability of the molten mass.

Step galvanizing

At this stage, the substrate immersed in a bath in which the molten zinc. The processes that are performed at this stage, will be presented by the destruction of the flux and interaction structures of the two metals. The duration of immersion depends on the size of the structure. This typically takes 5 to 10 minutes is Much more important to determine the optimal speed of immersion and extraction of the workpiece. For example, hot-dip galvanizing with a slow sinking rate will contribute to the liberation of metal from the pre-printed passivated coating.

On the other hand, higher speed leads to the seizure of salt residues on the surface, which inevitably lowers the quality of the result. Optimal speed is selected based on the size of the object, the durationimmersion and the surface characteristics.

Quality Control of hot-dip galvanizing

Mostly about the quality of the resulting product is judged by two characteristics: strength and coating thickness. To estimate these parameters specialists perform analysis of threaded connections and welded assemblies, which are considered to be most vulnerable from a technical point of view areas. As for checking thickness, it should be based on the requirements set by GOST. Hot dip galvanizing in accordance with the regulations must be made in such a way that the thickness in areas remote from the knurling, angles, and threads to 5 mm, corresponded to the design. Specific values of the parameters of the layer are determined based on the requirements of specific product, but the validation method must be carried out with the free sites.

How much is hot dip galvanizing?

The average cost of hot dip galvanizing is 30-35 thousand rubles. per 1 t In this case there are deviations from this corridor, if we are talking about custom orders. Affects the price tag and the condition of products. Often businesses offer a full maintenance cycle, which involves multi-stage hot-dip galvanizing. The price of the full cycle, which will and preparation, it can reach 50 thousand For this amount, as a rule, the use of quality reagents, drying the treated products in special chambers and confirmation of a job well done expert documentation.

Advantages and disadvantages

For large enterprises who work with large volumes of metal, this method of corrosion protection is optimal primarily for economic reasons. In addition, the technology provides a reliable barrier to the corrosion processes and at the same time does not reduce the performance of heat and conductivity of the material. On the downside, the hot-dip galvanizing of steel structures requires high flow components for the active mass and the careful organization of the overall process of treatment. The disadvantages of hot dip galvanizing can be attributed to the limitations of its application in relation to fine detail – the thin layer in this case to apply the transaction journal.

Conclusion

Protection Technology of metal plating is used quite a lot of years, and to this day it has no viable alternative. The prevalence of the method due to the fact that hot galvanizing efficiently copes with the main task – the prevention of rust. This reliable method has proved himself both in industry and in construction.

Where to the fore the issues of strength and durability of metal structures is justified and coating zinc.

Article in other languages:

BE: https://tostpost.com/be/b-znes/39581-garachae-cynkavanne-praces-acynko-k-metal-chnyh-vyraba.html

DE: https://tostpost.com/de/business/39051-feuerverzinkung-prozess-verzinken-metallwaren.html

HI: https://tostpost.com/hi/business/23651-galvanizing-galvanizing.html

KK: https://tostpost.com/kk/biznes/39921-ysty-myryshtau-process-ocinkovki-metall-b-yymdar.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Far-Eastern railway: history and characteristics

far East railway – the main passenger and freight artery linking the center of Russia with the areas adjacent to the Pacific ocean. Currently, the importance of this highway cannot be underestimated. More than a century of h...

Gas modular boiler: description, characteristics, photos

the Gas block boiler room is a transportable installation at the factory. It can work based on gas boilers, power range which varies from 200 to 10 000 kW. The hot water circuit can be optionally installed in addition. Design have...

Part time job for a teenager 15 years: job options

What could be the part time job for a teenager 15 years? To answer this question definitely will not work. In today's world even a minor aspire to earnings in varying degrees. So, the job is enough. But what options are suitable f...

cinder block – this is a very convenient building material for the construction of residential buildings of small height. Many home masters who have free time and desire to make the building blocks of their own, are trying t...

The Air Base Engels. Long-range aviation of the Russian air force

After the reform in 2009 of 245 bases of the Russian air force remained in force only 70. The rest was conserved or used today, but only periodically. Engels air base near Saratov is one of the largest of all functioning.Historyth...

Implemented products are... Price and volume of products sold

the Result of activity of any manufacturing company are finished goods held for sale to the final consumer. The set of sold goods manufacturer is called “implemented production”. This concept implies a number of not on...

Comments (0)

This article has no comment, be the first!