Now - 16:52:17

Deaerator - what is it? Types, structure, working principle

The boilers are often made of steel. Passing through them the water consists of oxygen and carbon dioxide. Both of these elements have on the metal structure of the boiler is extremely negative impact. Constant contact of steel with these gases inevitably leads to its rusting. In order to remedy the situation and prolong the equipment life, thermal cycle boiler includes special plant — the deaerator. What is it? And talk about this later in the article.

Definition

A Deaerator is a special equipment for removal of oxygen from the coolant of the heating system by heating the last ferry. Thus, in addition to the cleaning function, devices of this type perform well with heat. The same installation of deaeration can be used for heating and cleaning as nutritious, and makeup water.

Design Features

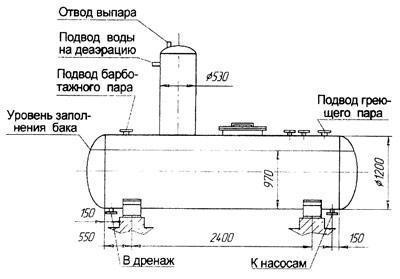

The relative simplicity of the design — this is what distinguishes the deaerator. What it is, we found out. Now let's see how to construct this equipment. Is a boiler deaerator tank (BDA) with mounted on it a vertical column (KDA) installed on supports. An additional element of equipment of this type is a hydraulic system that protects it against excessive pressure. Column is welded to the tank without flange — directly.

On the horizontal deaerator tank mounted input and output branch pipes for connecting of supply lines and discharge environment. Bottom set plum. Another element of the structure is designed to collect zagazovannogo water collecting tank. It is located under the bottom of BDA.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Hydraulic system equipment such as the deaerator, the scheme of which is presented below, usually consists of two hydraulic locks. One of them protects the device from any excessive pressure, and the second — from threat. Also, the design of the hydraulic system of the deaerator enters the surge tank. The steam from the deaerator, collected in a special cooler with a horizontal cylinder.

Construction of the column

The Column consists of a cylindrical shell with elliptical bottom shape. As for the tank, it has connections for supply and discharge of medium. Inside the column there are special plates with holes, through which water passes. This design allows to significantly increase the contact area of the environment and of steam, and therefore produce heat at the maximum speed.

Equipment

In the modern boilers can be installed deaerator water:

Vacuum;

The atmosphere.

In the first type deaerators removal of gases from water is carried out in vacuum. The design of such facilities addition of steam or water jet ejector. The last type of nodes is most often used in systems with boilers of medium or low power. Instead of ejectors to create a vacuum can be used special pumps. Some lack of equipment such as vacuum deaerator is the fact that the steam from it to forcibly remove, while from the outside it comes out naturally — under pressure.

In Addition to the two considered types of deaerators in the boiler may be installed, device elevated pressure. They work with 0.6-0.8 MPa. Sometimes in the heat circuit also turns on the boiler equipment of low pressure.

Application Area

Where the same can be applied to the deaerator? What it is, you now know. Since this device is designed for degassing the working medium, it is used mainly where there is heating equipment is made of steel.

Most Often deaerators are used in heating systems and domestic hot water. Boilers with hot water boilers are usually equipped with a vacuum type. Also in such schemes can be used deaerators atmospheric. Installing low and high pressure are used mostly in systems running through the work of steam boiler. The first type (for 0.025-0.2 MPa) is mounted in a not too powerful engines, are designed for a small number of consumers. Installation of high pressure used in the thermal schemes with boilers, feed large amounts of vapor.

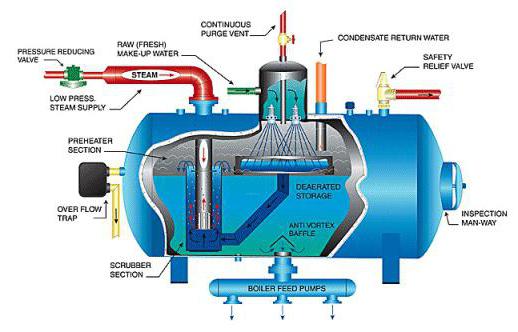

Disc deaerator principle of operation

The Scheme of gas purification in the deaerators is implemented two-stage: the jet (in the column) and a bubble (in the tank). In addition, the system is submerged bubbling device. Water is supplied to the column, where it is processed with steam. It further flows down into the tank, it is aged and is discharged back into the system. Couples initially served in the BDA. After ventilation of the internal volume it enters the column. Passing through the holes of the bubble plates, the steam heats the water to the saturation temperature.

An Inkjet method, the water removed from all of Gaza. Simultaneously, condensation occurs. Its remains are mixed withreleased from the medium gas and is discharged into the cooler. The condensate from the flash steam is discharged into the drainage tank. During settling of the water in the tank from it come the residual small gas bubbles. Given the water in the collecting tank. Sometimes the horizontal capacity is only used to defend. In such plants, the two stage degassing placed in the column.

Deaeration of make-up water

The Coolant in the heating system circulates continuously. But the volume of it over time, as a result of the leakage gradually decreases. Therefore, the heating system is supplied makeup water. As a major, she needs to go through the process of aeration. Initially, the water enters the heater, and then passes through filters chemical treatment. Further, as a nutrient, it enters the deaerator. Freed from the oxygen, the water flows to the charging pump. The latter directs it into the intake manifold or storage tank.

Chemical deaeration

Thus, the answer to the question about what the deaerator of the boiler, simple. This equipment, intended for boiling water hot steam to remove oxygen. Sometimes, however, the gases from the coolant in such installations are not fully removed. In this case, to further purify the water boiler can be added various reagents for binding oxygen. This can be, for example, sodium sulfite. In this case, for high-quality deaeration of water requires heating it. Otherwise, chemical reactions will occur too slowly. Also to speed up the process of binding oxygen can be used various kinds of catalysts. Sometimes water and degassed by passing through a layer of normal metal shavings. The latter in this case are rapidly oxidized.

Installation Features

The device of the deaerator is not too complicated. However, its installation must be carried out strictly in accordance with the provisions of technology. With the installation of such equipment is motivated primarily by the attached manufacturer's drawings and design of a boiler room. Before installation inspection of the installation and its re-activation. Discovered defects are removed. Actually, the setup procedure includes the following steps:

The tank mounted on the Foundation;

Welded it to the drain neck;

The lower part of the column is truncated on the outside diameter;

The column is installed on the tank (this is fixed inside of her plates should be placed horizontally);

The column is welded to the tank;

Mounted the cooler flash steam and water seal;

In accordance with the drawings, you can connect the trunks.

Set locking and regulating armature;

Conducted hydraulic tests of equipment.

Spray installation

The above-Considered structures called disc. There are also spray deaerators. Devices of this type are rarely used and represent a horizontal storage tank of large capacity. The absence of columns — this is what distinguishes such a deaerator. The principle of operation it is also a little different. Couples in these plants is coming from the bottom of the tank horizontally combs. The capacity is divided into a preheating zone and a deaeration. The feed water of the boiler is received in the first compartment located at the top of the dispenser. Here it is heated to the boiling point and enters the zone of aeration, where the steam bled of oxygen.

So that's all that can be said about this device, as the deaerator. What it is, I hope you understand, so we gave a fairly detailed answer to this question. So call the installation provides continuous operation of hot water and steam boilers. The choice of varieties and methods of installation of this equipment shall be in accordance with the technical characteristics of heating equipment and boiler project.

Article in other languages:

AR: https://tostpost.com/ar/business/22178-deaerator.html

BE: https://tostpost.com/be/b-znes/39656-deaerator---shto-geta-takoe-v-dy-prylada-pryncyp-pracy.html

HI: https://tostpost.com/hi/business/23805-deaerator.html

JA: https://tostpost.com/ja/business/21762-deaerator.html

KK: https://tostpost.com/kk/biznes/40060-deaerator---b-l-ne-t-rler-rylysy-zh-mys-steu-princip.html

TR: https://tostpost.com/tr/business/36591-deaerator---bu-nedir-t-rl-cihaz-al-ma-prensibi.html

UK: https://tostpost.com/uk/b-znes/40510-deaerator---scho-ce-take-vidi-budova-princip-roboti.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Ural automotive plant: history. Products, photo

the Automotive industry in Russia is constantly evolving. Today in our country operates 16 plants this specialization. One of the largest engineering companies is Ural automobile plant (the“motor vehicles.”), which pro...

Synchronous and asynchronous motor: differences, principle of operation, application

the Classification engines are based on different parameters. One of them, distinguish between synchronous and asynchronous motor. Differences of devices, General characteristics and operation are described in the article.Synchron...

TM "Holtz house": information about the company. Reviews about products and services

Wooden house - is not only fashion on environmentally friendly housing, is a return to a normal environment. It is the desire to live in harmony with nature due to the boom in the construction of houses of timber.the Technology of...

"Ikarus 256": technical specifications, fuel consumption and photos

Bus «Ikarus 256” it was manufactured from 1977 to 2002, the Hungarian automaker. The model was similar to the 250-th. The only difference was its length, which was one meter less. Compared with the previous modificatio...

Aircraft "su-24M2": description, specifications and history

the Plane «su-24M2” — new upgraded version, the prototype of which was «su-24” — bomber. There are only 2 crew, large compartments in the fuselage for weapons and bulk fuel tanks. Also there's a...

The franchise "Starbucks" in Russia

the Development and promotion of a recognizable corporate brand – almost the most important task for a novice businessman or already an established entrepreneur, contemplating the possibilities of new business ideas. But the...

Comments (0)

This article has no comment, be the first!