What is a flange connection? The types of flanges. Flange connections in the industry

In industry are often used flange connection. They should provide tightness and strength of assembled structures. The role of the quality of the connection is important, because the unstable bond may lead to large losses and threatened danger to the service personnel. The main connection element is a flange. This detail is a metal plate and provides a durable and tight plug connection. Application flange found in pipeline transportation, and utilities. Through the use of different materials for its production, it becomes almost universal element of pipeline structures.

Types of flanges

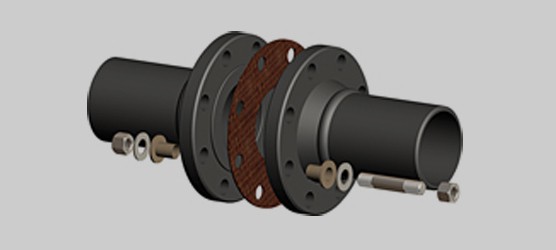

For process piping developed a large number of designs that detail. All flange connections consist of the following items – flanges, gaskets, fasteners. The main task which is assigned to this node – the Union of parts of the pipeline or connection to pipes of additional equipment. Flanges are divided into types depending on various parameters. By design, they are divided into:

- Solid;

- Loose.

The Difference lies in that the integral flanges together with the housing, respectively, undergo the same load. They are made together with the reinforcement during the casting or forging, and also the combination can be produced by welding. As for free, they are a disc that is attached to the welded flange or beaded end of the pipe. In both species there are both disadvantages and advantages. Loose flanges are easy to assemble, their design makes it easy to align the holes for the studs. The disadvantage is lower strength and stiffness than solid flanges.

The Difference lies in that the integral flanges together with the housing, respectively, undergo the same load. They are made together with the reinforcement during the casting or forging, and also the combination can be produced by welding. As for free, they are a disc that is attached to the welded flange or beaded end of the pipe. In both species there are both disadvantages and advantages. Loose flanges are easy to assemble, their design makes it easy to align the holes for the studs. The disadvantage is lower strength and stiffness than solid flanges.

The Separation of flanges for the purpose:

- To valves and piping. Flange connections of pipelines of this type are used for all types and pipe industries, transport and housing and communal services.

- For vessels and equipment, such compounds are used for distillation, equipment systems, heating and tanks for the reservation.

Standards

All flanges are divided into several types depending on the standard and versions:

- Alloy flanges, are manufactured as a single unit with the body. They can be cast from steel or cast iron.

- Steel flanges, which are threaded on the neck. This type is of limited use and is mainly used for pipelines with low pressure.

- Collar flanges. Represent the product of steel, which is obtained by butt-welding. The appointment of the collar flange is the connection of pipelines of high and medium pressure. The advantage of this type is ease of installation and economy. Compared to a flat weld flanges, which we will discuss in the following paragraph, they reduce the complexity of manufacturing on average 20% and the volume of work on welding two times.

- Flanges welded. They are produced from steel and are flanged connections for the process piping.

- Loose flanges. This species has its own characteristics and is subdivided into three subspecies:

- With collar, they are used for pipelines with aggressive media, from the effects of which the collar prevents the flange;

- Flanged pipe;

- On the welded ring, they are used for pipelines of non-ferrous metals – copper and its alloys, aluminum and stainless steel;

Options select the connection

- Form a flange connection. Flanges can be round, oval or rectangular.

- Conditional pass. Its size corresponds to the inner cross section of the flange, which will take place Wednesday.

- Design. This option reglamentary flange connections, GOST 12815-80 includes 9 different categories of performance.

- Pressure. Connections can withstand the maximum nominal pressure, it depends on the design and the geometric dimensions of the flange. This option also provides the main regulatory document.

- Material. Used for the manufacture of cast iron, carbon steel, alloy steel, stainless steel. Material is selected according to the environment you use. Can also be used costly metals.

The connection is electrically insulating tunic

Insulating flange connection has a number of differences from other species and bears the problem of barriers to the passage of electric current, and electrochemical corrosion protection. Most pipelines are placed underground, where possible, the likelihood of stray currents. In General they are not dangerous to the entire inlet, but verythreat on it. Such exposure can lead to the destruction of the metal, cracking and leakage of the transported liquid or gas, insulating flange joint provides the necessary security. It consists of flanges, special insulated spacers, bushings and fasteners. Apply this connection in the following cases:

Insulating flange connection has a number of differences from other species and bears the problem of barriers to the passage of electric current, and electrochemical corrosion protection. Most pipelines are placed underground, where possible, the likelihood of stray currents. In General they are not dangerous to the entire inlet, but verythreat on it. Such exposure can lead to the destruction of the metal, cracking and leakage of the transported liquid or gas, insulating flange joint provides the necessary security. It consists of flanges, special insulated spacers, bushings and fasteners. Apply this connection in the following cases:

- The pipeline on the border and move it from supplier to consumer;

- When the flange connection of pipes provides a combination of different materials from which they are made;

- On the pipelines, which are laid in stray currents sources;

- The output is isolated the pipeline network, which connects non-insulated tubing;

- On ground stations gas distribution stations.

Other types of flange connections

- Measurement of the flange. They provide a docking pipeline networks, auxiliary equipment and measuring devices.

- Connections working under high pressure. Such nodes are subjected to variable loads from the working mechanisms. Therefore, to ensure density and strength as well as durability, you should follow some technological nuances of the installation. Tightening the studs staggered in a circle and in a specific sequence. The flange connection can become stronger through the use of lens view of the strip. To use this kind of pads, you must grind the surface and strips, and pipes directly. The best option for this are a threaded flange connection. Can also be used along with the lens gasket, flat metal.

Maximum density of a flange connection is provided by using such materials for flat gaskets, such as copper or aluminum.

- Flange lock. the connection design fully complies with the flange, the difference is that instead of the usual fasteners – bolts and studs, use the special design in the form of a strip, which compresses the flanges and tighten the bolts. In such compounds hole the diameter of the flanges do not exist. This kind has proven itself in knots that require quick and periodic separation connection. To use this case flat welded flanges or butt welded.

Flange wizard

For the installation of flanged joints necessary fasteners. For attachment of pipelines used such fasteners: bolt, nut, stud and washer. As flange connections in the pipelines is responsible enough design, to the fixture requirements in accordance with the following parameters:

- Environment. She can be aggressive and not. Based on this environment option is selected fasteners. For aggressive environments the preference is given to steel with anti-corrosion properties. It is also possible to use special coatings that prevent corrosion.

- Temperature. It plays the role of the temperature of the liquid or gas that will be transported on this pipeline, as well as temperature of the environment. Each material has a working temperature range, whereby a selected product. If the environment does not exceed –30 ºC, it is possible to use of conventional steel grades, at lower temperatures, applied cold stamps.

- Pressure. The higher the operating pressure, the higher options should have used the material of studs for flange connection.

- Performance fasteners: thread type, pitch, length.

- Material. Steel, which is used in the production of fasteners for the flange connections can be classified into four categories:

- Carbon steel General purpose operating temperature should not exceed the figure of 200 ºC, and the maximum diameter – 48 mm;

- Carbon steel used for products of high precision, operating temperature notcan be higher than the values of 300 ºC;

- Carbon steel with high quality fasteners made from this material can operate at temperatures above 450 ºC;

- Alloy steels, which possess heat-resistant and anticorrosive properties.

The Limited use of fasteners

The Choice of fasteners due to the above parameters, but there are some limitations:

- Fasteners operated at an operating pressure of 25 kgf/cm, limited by the choice of the type of the product. As for the pressure, which exceeds this figure, you can only use studs for flanged joints, the use of bolts is prohibited.

- Steel Grade for the pair of “pin–nut" can be selected as the same and different. If you are using one material, the strength of the nuts should be below the strength of the studs 20 units.

There is a special GOST studs for flanged joints, in accordance with which selects the nominal sizes of fasteners. The choice of size depends on the working pressure, which will be subject to the hairpin.

Strip

This item is included in the insulated flange joint, to ensure the necessary tightness between flanges. The strips are divided into different types according to certain parameters. Depending on the material from which they are made, there are categories:

- Metal;

- Metal;

- Composite.

Distribution of the pads of elasticity:

- Firm;

- Hard.

This property determines the material of gasket for flange connection. Elastic work of composite and non-metallic types. Hard pads are mostly metal and non-metal, obtained from such materials as fiber, hard rubber, paronite, etc.

Design features strips

On this basis the gaskets for flanged joints are divided into:

- Flat (can be metal, non-metallic and combined), they are used in connection with flat surfaces. The inner diameter of the flat gasket must be greater than the pipe diameter of 1-3 mm.

- Lens gaskets made from carbon and alloy steels, they can be both rigid and elastic.

- Oval provide a reliable seal, while the load on the bolts rather moderate. The contact of the intermediate product occurs at the outer and inner circumference with a flange. The material for these pads is carbon or stainless steel.

- Corrugated gaskets can be both metallic and non-metallic. They are made of thin sheet copper, soft steel, as the material is non-asbestos Board or paper. Inner diameter corresponds to the diameter of the flange, and the outer adjusts the location of the bolts.

- Spiral belong to the elastic strips. The gasket consists of three elements – a helical part and two restrictive rings.

- Serrated gasket material for these pads is low carbon or alloy steel. Insulated flange connection type gasket may be used at temperatures not exceeding 480 ºC.

Calculation of flange connections

After determining the type of the flange, depending on its purpose, type of gasket products, as well as the materials from which the product will be manufactured, the designers selected the required dimensions of items on special tables. They are presented in the relevant Standards. Despite the fact that the flanges are standard parts, it is very often necessary to design customized products. The calculation system includes the following items:

- Calculation of plastic deformations in the base bushings, it concerns compounds that operate at low temperatures and pressures.

- Extenal bending moment arising from loads on the bolts. This parameter determines the strength characteristics of the flange.

- Calculation of the stresses, especially for goods that are received by welding.

- Variety of step bolts, incorrectly identified this option may cause deflection of the ring flange between the bolts.

Calculation of flange connections must take into account the variation of the load. There are two options – in the first case the load from the bolts is transmitted to the gasket in the second – there is a uniform load distribution between the spacer and the support ring.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

In Poland Enters Into Force A New Law In The Field Of Consumer Protection

In Poland, 25 December 2014 entered into force the new provisions on consumer protection, which was developed by the Ministry of Justice taking into account directives of the European Parliament and the European Council. The Minis...

Business process - what's that? Development, modeling, optimization of business processes

Modern methods of company management increasingly adopt foreign methods and technologies. And not because it's fashionable, but because it is convenient and efficient. One of these techniques breaks all the routine work on the ele...

The name of your company: examples. How to come up with a nice original name for the company

If you decide to create your company, special attention should be given to its name. Because, as they say, as you would call a boat so it will float to that point must be approached very responsibly and carefully. Our article will...

Industrial washing machines differ from consumer models in that in most cases have better performance and other modes and cycles of operation. Of course, it should be noted that even with the same technical settings professional m...

Types of strategies in business. Types and forms of enterprise development strategies

a Key component of any process management – strategy. Within its framework it is regarded as a long-term detailed directions regarding the development of the company (in particular, the strategy for the sector, forms and mea...

The biggest aircraft carriers in the world. Modern aircraft carriers of the world

USS – ship combat and strategic purposes. The main striking power is the aircraft located on the deck. These giants have everything for repair, maintenance, and temporary storage of helicopters and airplanes. To date, all ex...

Comments (0)

This article has no comment, be the first!