Now - 17:13:52

What is recrystallization annealing?

This article presents a fairly detailed account of what constitutes recrystallization annealing. In addition, for information will be reviewed and other types of work with steel, which improves the structure and workability of the metal, reduce the hardness and relieve internal stresses. From the structure of the alloy depend on all its main properties, and a method of changing the structure is the heat treatment. Recrystallization annealing, and many other types of heat treatment by D. K. Chernov, next, this theme was developed by G. V. Kurdyumov, A. A., Bochvar, A. P. Gulyaev.

Heat treatment

A collection of different heating operations with the help of special equipment and special technology, shutter speed and cooling, which are executed strictly in sequence and in accurate modes to change the internal structure of the alloy and to obtain the desired properties. Heat treatment is divided into several types. The annealing of the first kind, which is used for absolutely any metals and alloys, phase transformations in the solid state brings. Recrystallization annealing is used to achieve the following characteristics.

During the heat of the annealing of the first kind increases the mobility of the atoms, a fully or partially eliminated by chemical heterogeneity, reduced internal stress. It all depends on the heating temperature and exposure time. Slow cooling here is typical. Variations of this method are annealed for stress relief after the casting, weld or forging, diffusion and recrystallization annealing.

Recommended

"Knowledge is light and ignorance is darkness": the value, meaning and alternatives

There are some sayings that would seem to need no explanation, such as “teaching & ndash; light and ignorance – darkness”. But some still do not understand their meaning. But not only for such people is written by our article. I...

What was invented by Mendeleev for the army. The history and fate of the invention

D. I. Mendeleev was a brilliant Russian scientist-polymath, who made many important discoveries in various fields of science and technology. Many people know that he is the author of “Fundamentals of chemistry" and the periodic law of chem...

The origin of the Slavs. The influence of different cultures

Slavs (under this name), according to some researchers, appeared in the story only in 6 century ad. However, the language of nationality bears the archaic features of the Indo-European community. This, in turn, suggests that the origin of the Slavs h...

Joke of the second kind

This joke is also metal alloys which experience phase transformation during annealing in the solid state and when heated and when cooled. Here the purpose is somewhat broader than those which are pursued by the recrystallization annealing of steel. After annealing of the second kind is a more equilibrium structure for further processing of the material. The graininess disappears, crushed, increase the viscosity and plasticity are significantly reduced hardness and strength. This metal can already be cut. Heating is carried out to temperatures far above the critical, and cooling is carried out with the oven - very slowly.

Also, the thermal treatment is annealing of the alloys for strength and hardness. Here, by contrast, the non-equilibrium structure is formed, which increases these parameters at the expense of sorbitol, troostite, martensite. The temperature used is also significantly above the critical, but cooling occurs at very high speeds. The fourth type of heat treatment - a vacation that relieves internal stresses, reduces hardness and increases toughness and ductility of hardened steels. When heated to temperatures below the critical cooling rate can be any. The transformation reduces the nonequilibrium structure. So acts and normalizing annealing of steel.

Selection mode

Thermal processing may be preliminary and final. The first is used for the preparation of material properties and structure for further technological operations (improving machinability, cutting, shaping pressure). Final heat treatment are formed all the properties of the finished product. How to select the mode of recrystallization annealing, depends on the process and purposes of heat treatment.

Means the heating of the alloy or metal higher than the crystallization temperature, and no less than one or two hundred degrees. Followed by aging at this temperature for the required time. Cooling is the final stage of this process. This technology is subdivided into complete, incomplete, and texturizing annealing, and the choice depends on what is the purpose of recrystallization annealing.

Annealing

In practice, the most frequently used in full annealing, but here you need to pay attention to the fact that the annealing of steel and its hardening process is different. In the recrystallization annealing are performed certain procedures that precede the cold processing of metal under pressure to ease further with him, or annealing is an output form of heat treatment, when the finished product or semifinished product is getting the desired characteristics. Either this operation is intermediate, for example - for effective removal of work hardening.

For a homogeneous dissolution in the matrix of alloying elements and to obtain uniform microstructure with the same material properties, annealing is performed in a special solution. Black metal requires a recrystallization annealing with temperatures from 950 to 1200º C using a solution of salts Durferrit Glühkohle or Durferrit 960 GS. Non-ferrous metals are annealed at temperatures from 460 to 540º C with the use of salts Durferrit A. V., may be followed by subsequent processing to increase the strength.

Purpose

The Most commonly recrystallization annealing of steels is carried out with the aim of bringing the structure of the material to the desired parameters, which are necessary for further work. It is used after processing pressure, if slow recrystallization is not fully completed, and it is not possible to removehardening.

This technology is usually applied to hot-rolled coils made of alloys, which is the basis for aluminum, and also after cold rolling of sheets, strips, foil of different alloys and non-ferrous metals (here it should be mentioned recrystallization annealing of Nickel), bars and wire steels for cold forming and pipe cold drawing. A separate procedure is annealing in the manufacture of semi-products and products of non-ferrous metals (including Nickel).

Temperatures

Different materials require different modes of heat treatment. The entire process typically lasts no more than one hour to complete recrystallization annealing, but the temperature for each alloy is your own. So from 300 to 400 °With demand-based alloys of magnesium, 800 to 1150 °C - Nickel alloys, from 650 to 710 °C - carbon group of steels, which are necessarily conducted recrystallization annealing. Melting point, of course, is not achieved.

Aluminum alloys so much just from 350 to 430 °C and pure aluminum recrystallizes at temperatures from 300 to 500 °C. From 670 to 690 °C requires recrystallization of titanium, from 700 to 850 °C - composition of copper and Nickel, from 600 to 700 °C need bronze and brass, and pure copper even smaller, she starts recrystallization from 500 °S. These modes recrystallization annealing is required to separate metals and alloys.

Diffusion treatment of metals

This kind of annealing is also called homogenizing, and held for the purpose of elimination of the consequences of dendritic segregation. Diffusion annealing is needed for alloy steels where increased plasticity and reduced viscosity due to crystal phase separation, which leads to layered or brittle fractures. It is necessary to achieve the equilibrium structure, and therefore a diffusion treatment of cast metal is necessary. In addition, it improves mechanical properties and increases homogeneity of properties throughout the volume of the finished product.

Here's what happens in this process: dissolve the excess phase, is aligned with the chemical composition emerge and grow the pores, increases the grain size. This type of heat treatment requires a long exposure of the metal under conditions of temperature above the critical (here you can talk about 1200 degrees centigrade).

Isothermal heat treatment

This is recommended for annealing of alloy steels, where at constant temperature, the austenite decomposes into ferrite and the cementite in the mixture. Such a collapse can occur with other types of annealing, if there is a gradual cooling due to the constant and consistent temperature reduction. Thus achieving uniformity of structure, reduced time for heat treatment.

Schema the isothermal annealing follows: first heating to a target, which would exceed the upper critical point of 50-70 degrees, then reduce temperature to 150 degrees. After that the heated part is transferred into a furnace or bath which is maintained at a temperature of 700 °C. the duration of the procedure will depend on the composition of the metal and the geometric dimensions of the part. Alloy compositions may require several hours, and hot rolled carbon steel sheets - a few minutes.

Distinctions

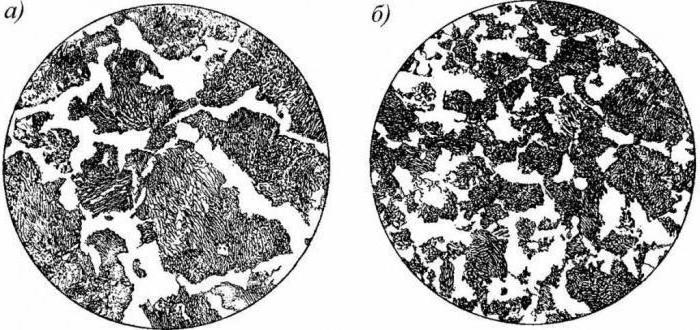

When full annealing is provided by recrystallization of the steel, relieving the metal from a variety of structural defects. Steel gets his most important and characteristic properties are relaxed for subsequent cutting. You must first heat it to a temperature above AC3 by 30-50 degrees, to warm up, then cool down slowly.

Most Often, the extract lasts for at least half an hour, but no more than hours per ton of steel with a heating speed of 100 degrees centigrade per hour. The rate of cooling varies - depends on the steel composition and the stability of the austenite. If cooling is fast, can be formed too solid ferritic-tsementita disperse structure.

Cooling

The Rate of cooling is regulated by cooling the furnace with gradual disabling and opening the door. In full annealing, the main thing - not to overheat the alloy. Incomplete annealing is performed at temperatures below AC3, but slightly above AC1.

Then steel partially perekristallizatsii that defects won't. So treat the steel with a ferritic lack of poloschatosti if they only need to soften before further processing and cutting. In addition to full and partial there are still recristalizacion texturizing annealing.

Usage

Sometimes the annealing completes the hot working (hot-rolled coils, for example, of aluminum alloy, annealed before cold rolling to remove work hardening, which is necessarily formed as a consequence of hot rolling).

Much more widely used, the annealing of this species in the manufacture of products and semi-finished products from alloys and pure metals. It's an independent operation of heat treatment. Compared with the steels a huge amount of non-ferrous metals subjected to cold processing by pressure, and then recrystallization annealing is required.

Industry

If you need granular form of cementite,aging of alloy during the annealing to complete recrystallization can last long - a few hours. For cold deformation, which is usually followed by annealing, the most favorable granular form of cementite that occurs during recrystallization in the process of the birth and growth of undeformed grains, and this requires heating to a certain temperature.

Recrystallization annealing in the industry is the initial operation to make the alloy or metal ductility prior to cold pressure treatment. Not less often it is present in the interval between the operations of cold deformation to release work hardening, and as an output the final heat treatment process, to ensure that the product or semifinished product has acquired the necessary properties.

How it happens

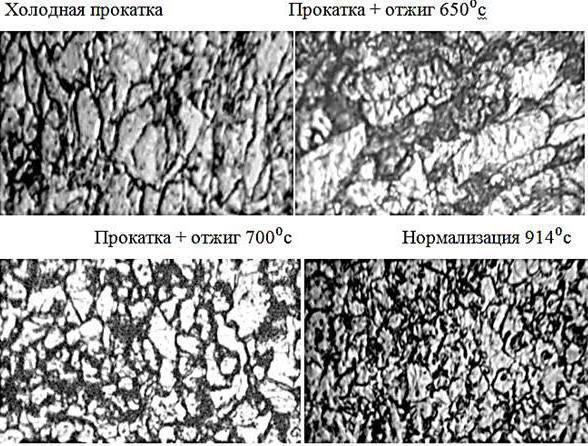

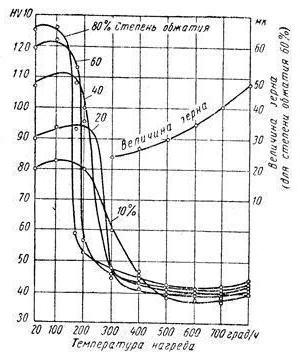

When Heated, the deformed metal increases the mobility of atoms. Old grain stretch, become vulnerable, intensely originate and grow a new, equilibrium and free from stress granules. They are faced with the old, stretched out, absorbing in its growth to their complete disappearance. Recrystallization of steel and alloys and is the main purpose of recrystallization annealing. During heating after reaching the required temperature yield stress and strength of the material decrease rather sharply.

But increases the ductility, it works to improve machinability. The temperature of beginning of recrystallization is called the threshold of recrystallization. As it reaches the metal ezuprechnaya. The temperature cannot be constant. For a specific alloy or metal play equally important roles in the heating time, the degree of pre-strain, the original grain size, and more.

Article in other languages:

AR: https://tostpost.com/ar/education/9791-what-is-recrystallization-annealing.html

BE: https://tostpost.com/be/adukacyya/17210-shto-takoe-rekristallizacionnyy-adpal.html

DE: https://tostpost.com/de/bildung/17045-was-ist-rekristallizacionnyy-ausgl-hen.html

ES: https://tostpost.com/es/la-educaci-n/17000-qu-es-rekristallizacionnyy-recocido.html

HI: https://tostpost.com/hi/education/9677-recrystallization-annealing.html

JA: https://tostpost.com/ja/education/9677-what-is-recrystallization-annealing.html

KK: https://tostpost.com/kk/b-l-m/17272-b-l-rekristallizacionnyy-k-yd-ru-kerek.html

PL: https://tostpost.com/pl/edukacja/17810-co-to-jest-rekristallizacionnyy-art.html

PT: https://tostpost.com/pt/educa-o/17671-o-que-rekristallizacionnyy-recozimento.html

TR: https://tostpost.com/tr/e-itim/17196-nedir-rekristallizacionnyy-tavlama.html

UK: https://tostpost.com/uk/osv-ta/17459-scho-take-rekristal-zac-yne-v-dpal.html

ZH: https://tostpost.com/zh/education/9786-what-is-recrystallization-annealing.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Epistemology and the main approaches to the knowability of the

epistemology is the study of the process of accumulation of new knowledge about how humanity understands the world and the causal relationships acting therein. No one doubts that from generation to generation we pass on to our des...

the – it is a theoretical index. It specifies how many you need to reduce the production of one product to produce other unit of such goods at the expense of the seized funds. an Alternative value can be a constant and growi...

The Nile and other major rivers of Africa

the Major rivers and lakes of Africa play a very important role for the continent, because by them it is watering and irrigation. On large streams a number of reservoirs, the total amount of which exceeds fifteen cubic kilometers....

The Berlin crisis of 1948 – the first confrontation between the former allies

From June 24, 1948, the former capital of Germany endured the blockade. It lasted almost a year. The city lacked food, fuel, and all of the household items, without which people's lives very difficult.the War ended three years ago...

Who first climbed mount Everest? In what year was mount Everest?

Republic of Nepal, known as the birthplace of the Buddha, is the most mountainous country in the world. On the North side it is bordered by Great Himalayan range, is famous for several peaks exceeding 8000 meters, including the Ev...

"Headlong": meaning of the idiom, the meaning and the situation of use

In this era where time is very valuable and the rate of reaction, particularly important expressions related to speed. Therefore, we analyze in detail the "headlong": meaning of the idiom and situation of its use.Origins...

Comments (0)

This article has no comment, be the first!