Now - 21:46:06

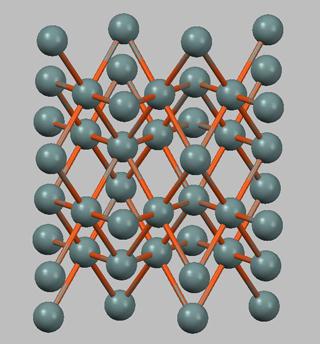

Bronze is an alloy. Characteristics of bronze

Bronze is an alloy based on copper. The auxiliary metal may be Nickel, zinc, tin, aluminum and others. In this article we consider the types, technological characteristics, chem. the composition of bronze, and the methods of its manufacture.

Classification

1. The chemical composition of the metal can be divided into two groups. First – it is a tin bronze. They tin is the main alloying element. Second – without tin. Below we will talk about this in more detail.

2. On technological grounds, the bronze can be divided into deformable and casting. The first is well-processed under pressure. The second is used in mold castings.

This metal compared to brass has much better friction, mechanical properties and corrosion resistance. In fact, bronze is an alloy of copper and tin (as primary support element). Nickel and zinc here are the main alloying elements, to do this, use components such as aluminum, tin, manganese, silicon, lead, iron, beryllium, chromium, phosphorus, magnesium, zirconium, and others.

Tin bronze: cast

Let's see, what is this metal. Tin bronze (photo below shows the castings) is an alloy, which has fluidity lower than that of other species. However, it does not have a significant volumetric shrinkage, which allows to obtain a shaped bronze casting. These features make active use of bronze in the casting of bearing parts. Also considering the alloy used in the manufacture of fittings designed for use in the aquatic environment (including sea water) or in water vapor, oils and under high pressure. There are so-called non-standard cast bronze of responsible purpose. They are used in the manufacture of bearings, gears, bushings, pumps, allopatrically rings. These parts are designed to work under high pressure, at high speeds and low loads.

Recommended

"Knowledge is light and ignorance is darkness": the value, meaning and alternatives

There are some sayings that would seem to need no explanation, such as “teaching & ndash; light and ignorance – darkness”. But some still do not understand their meaning. But not only for such people is written by our article. I...

What was invented by Mendeleev for the army. The history and fate of the invention

D. I. Mendeleev was a brilliant Russian scientist-polymath, who made many important discoveries in various fields of science and technology. Many people know that he is the author of “Fundamentals of chemistry" and the periodic law of chem...

The origin of the Slavs. The influence of different cultures

Slavs (under this name), according to some researchers, appeared in the story only in 6 century ad. However, the language of nationality bears the archaic features of the Indo-European community. This, in turn, suggests that the origin of the Slavs h...

Lead bronze

This subspecies casting tin alloys used in the manufacture of bearings, oil seals and shaped castings. These bronze are characterized by low mechanical properties, resulting in the process of making bearings and bushings they are simply applied to the steel base in the form of a very thin layer. Alloys with a high tin content have higher mechanical properties. They can therefore be used without the steel base.

Tin bronze: wrought

Alloy pressure treated, can be divided into the following groups: tin-phosphorus, tin-zinc and tin-zinc-lead. They found their application in the pulp and paper industry (they make meshes) and engineering (the manufacture of springs, bearings and machine parts). In addition, these materials are used in the manufacture of bimetallic products, rods, ribbons, strips, gear wheels, gears, bushings and spacers of heavily loaded machines, tubes, instrumentation, gauge of the springs. In electrical engineering the widespread use of bronze (wrought) is due to the excellent mechanical properties (along with the high electrical characteristics). It is used in the manufacture of current-carrying springs, plugs, contacts. In the chemical industry of tin bronzes produce spring wire in precision mechanics – rebar, in the paper industry – scrapers, in the automotive and automotive – bushings and bearings.

These alloys can be supplied in especially hard, hard, semi-hard and soft (annealed) state. Tin bronze is usually processed cold (by rolling or drawing). Hot metal is only subjected to compression. Pressure bronze handled perfectly both cold and hot.

Beryllium bronze

An alloy belonging to the group of dispersion-hardened metals. It has high mechanical, physical and elastic properties. Beryllium bronze has a high level of heat resistance, corrosion resistance and cyclic strength. It is resistant to low temperatures, is not magnetic and does not give sparks upon impact. Hardening of beryllium bronze is carried out at temperatures 750-790 degrees Celsius. The addition of cobalt, iron and Nickel contributes to the thermal treatment the slow phase transformations, this significantly simplifies the technology of aging and hardening. Furthermore, the addition of Nickel increases the temperature of recrystallization, and manganese can replace, though not in full, expensive beryllium. The above characteristics of bronze allowed to use this alloy in the manufacture of springs, spring details, as well as membranes in the watch industry.

An Alloy of copper with manganese

This bronze is a special high mechanical qualities. She handled the pressure like a cold, still hot. This metal is characterized by high heat resistance, and corrosion resistance. An alloy of copper with added manganese is widely used influe fittings.

Silicon bronze

It's an alloy which includes Nickel, at least - manganese. This metal differs extremely high mechanical, anti-friction and elastic properties. While silicon bronze does not lose its ductility in low temperature. Alloy well soldered, processed by pressure and at high and at low temperatures. The considered metal is not magnetic, and does not spark upon impact. This explains the wide use of bronze (silicon) in the marine in the manufacture of friction parts, bearings, springs, radiators, evaporators, grids and guides.

Tin Casting alloys

This type of bronze has good corrosion, anti-friction properties and high strength. They are used for the manufacture of parts operating in severe conditions. This, for example, gears, valves, bushings, gears for power turbines, and cranes, the worms who work in the two-seater with hardened steel parts bearings operating in high pressure environments and under shock loads.

How to make bronze?

The Manufacturer of this metal should be carried out in special furnaces used for melting copper alloys. The charge for bronze can be made from fresh metals or with the addition of secondary waste. The smelting process is usually carried out under a layer of flux or charcoal.

The Process using a batch of fresh metals occurs in a certain sequence. First in a very hot oven loaded with the necessary amount of flux or charcoal. Then there are placed copper. Waiting for it melt, increase the temperature to 1170 degrees. After that, the melt must deacidify why add copper. This process can be carried out in two steps: directly to the furnace, and then into the bucket. In this case, additive is introduced in equal proportions. Next, add in the melt heated to 120 degrees required alloying elements. Refractory components should be administered in the form of ligatures. Next, molten bronze (photo below demonstrates the process of melting) is stirred until complete dissolution of all added substances and is heated to a predetermined temperature. Upon issuance of the resulting alloy from the furnace before casting, it is necessary to completely deoxidizing the remainder (50%) phosphorous copper. This is done to release the bronze from oxidation and improve fluidity of the melt.

Production from recycled materials

To make bronze using the secondary metals and waste, smelting should be done in the following order. First melt the copper and phosphorous deoxidized her supplements. Then added to the melt circulating materials. After that waiting for complete melting of the metal and introduce alloying elements in the appropriate sequence. In that case, if the charge consists of small number of pure copper should first be melted metals working and then add the copper and the alloying elements. Melting is carried out under flux or charcoal.

After melting of the charge and heated to the desired temperature the final deoxidation of a mixture of phosphor copper. Next, the melt is served on top of calcined coal or dried flux. Consumption of the latter is 2-3 percent by weight of the metal. The heated melt is aged for 20-30 minutes, stirring periodically, and then its surface is removed a dedicated slag. All ready for bronze casting. For better removal of slag in the ladle, you can add silica sand, which thicken it. To determine whether the bronze casting in shape, there is a special technology preview. The break of the sample must be uniform and clean.

Aluminium bronze

It is an alloy of copper and aluminium as alloying element. The smelting process of this metal is significantly different from the above, due to chemical characteristics of the support component. Consider how to make bronze using aluminum alloy components. In the manufacture of this type of alloy using recycled materials in the charge operation by reducing phosphorous components do not apply. This is because phosphorus has a lower affinity for oxygen molecules than aluminum. You should also know that this type of bronze is very sensitive to overheating, so the temperature should not exceed 1200 degrees. In the overheated state, the aluminium is oxidized, and the bronze alloy becomes saturated with gases. In addition, the oxide formed during melting of this kind of bronze, is not restored by the addition of deoxidizers, and it is very difficult to remove from the melt. The oxide film has very high melting point, which significantly reduces the fluidity of bronze and causes the marriage. Melting is carried out very intensively, at the upper limits of the heating temperature. In addition, it is not necessary to hold the finished melt in the oven. When melting aluminum bronze as a covering layer it is recommended to use a flux which is 50% of soda ash and 50% of cryolite.

Ready to melt before casting on the forms refining by introducing himchloride of manganese or chloride of zinc (0,2-0,4% of the total weight of the charge). After this procedure, the alloy must withstand five minutes until the complete cessation of gassing. Then the mixture is brought to the desired temperature and is poured into molds.

To prevent segregation in the melt of bronze with a high content of lead impurities (50-60%) it is recommended to add 2-2,3% Nickel in the form memnoniella ligatures. Or as a flux it is necessary to use a sulfate salt of alkali metals. Nickel, silver, manganese, if they are part of bronze, should be added to the liquid before the treatment additives of tin. In addition, to improve the quality of the alloy it is sometimes modified minor additions based on refractory metals.

Article in other languages:

AR: https://tostpost.com/ar/education/19020-bronze-is-an-alloy-characteristics-of-bronze.html

BE: https://tostpost.com/be/adukacyya/36234-bronza---geta-spla-haraktarystyk-bronzy.html

DE: https://tostpost.com/de/bildung/35900-bronze-ist-eine-legierung-eigenschaften-bronze.html

HI: https://tostpost.com/hi/education/20711-bronze-is-an-alloy-characteristics-of-bronze.html

JA: https://tostpost.com/ja/education/18680-bronze-is-an-alloy-characteristics-of-bronze.html

KK: https://tostpost.com/kk/b-l-m/36531-ola---b-l-orytpasy-sipattamalary-ola-d-u-r.html

PL: https://tostpost.com/pl/edukacja/37776-br-z-to-stop-w-a-ciwo-ci-br-zu.html

PT: https://tostpost.com/pt/educa-o/37553-o-bronze-uma-liga-caracter-sticas-do-bronze.html

TR: https://tostpost.com/tr/e-itim/33005-bronz-ala-m-zellikleri-bronz.html

UK: https://tostpost.com/uk/osv-ta/36828-bronza---ce-splav-harakteristiki-bronzi.html

ZH: https://tostpost.com/zh/education/13509-bronze-is-an-alloy-characteristics-of-bronze.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

How to calculate the volume of right geometric solids

throughout our lives we have to calculate the volume of certain geometric shapes. For example, during construction it is necessary to correctly calculate the amount of trenches and excavations. In addition, this value is determine...

the Task of referees is to thoroughly monitor compliance with the rules of the game, rules of competition and to be objective in determining the winner. Their entire lineup involved in service specific event, United for a judgeshi...

Glaciology - the science of what? That study glaciologist?

Glaciology – is the science about? What do the professionals that work in this field? Let's try to find the answer to these and other questions.Glaciology what is studying?the Term comes from the Latin word ‘glacies&rd...

Conjugation of verbs in the English language: categories and features

In the famous language of England is the most complicated topic in the grammar, which is connected with the theme verbs and their modifications and used in different times. All times in the language of 16, but 9 of them are the mo...

The formation of the Ancient Russian state

the prerequisites for the formation of the ancient Russian state emerged as a result of influence of external and internal, spiritual, political, socio-economic factors. However, first and foremost, be aware of the economic change...

Russian state University of tourism and service (RGUTiS): reviews, address, faculties

In all educational institutions, an important role is played by the atmosphere in which learning takes place. The fact that it's developing identity, is the establishment of specialists. Russian state University of tourism and ser...

Comments (0)

This article has no comment, be the first!