Turning wood: art or craft

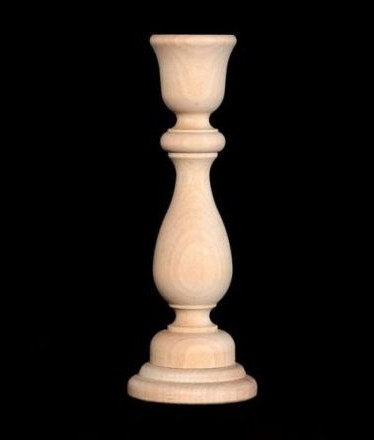

In this article we will introduce you to the fundamentals of manufacturing products, which can own hands to carve on a lathe. Turning wood is the artistic processing of wood, ranging from candlesticks and finishing balusters for staircases. The process of grinding is quite complex and consists of several components: selection of the workpiece and the tool, determine the speed of rotation of the workpiece, directly grinding and subsequent finishing. Sometimes the finished product requires the processing of varnish, the intermediate of the polishing and drying. But first, choose blank. Rules are simple, the first thing you need to determine the dimensions of the product in finished form.

Suppose we want to carve the candle. Have a drawing showing all dimensions, length 45 mm, diameter - 48 mm at the base and 35 mm - diameter tops, where to place the candle. The workpiece is chosen with the expectation – length plus 8 cm, if your lathe is equipped with a wood Cam cartridge, and the length plus 4 cm, if the machine spindle with a faceplate. The thickness of the workpiece should be with a margin of 20 mm, that is, for a given diameter of 48 mm, the workpiece will have a diameter of 68-70 mm.

Suppose we want to carve the candle. Have a drawing showing all dimensions, length 45 mm, diameter - 48 mm at the base and 35 mm - diameter tops, where to place the candle. The workpiece is chosen with the expectation – length plus 8 cm, if your lathe is equipped with a wood Cam cartridge, and the length plus 4 cm, if the machine spindle with a faceplate. The thickness of the workpiece should be with a margin of 20 mm, that is, for a given diameter of 48 mm, the workpiece will have a diameter of 68-70 mm.

Great importance is the grade of wood that you will carve candle. The fact that turning wood is only possible when using hard wheat. Conifers categorically do not fit, they can be immediately forgotten. Respond well to turning: beech, ash, pear, Apple, cherry, oak, hornbeam, chestnut and others about the same hardness. In addition to hardness, the value is the texture of the material. Turning wood give good results, if the wood is beautiful. Plain varieties in the finished product will not look good. For example, beech, hornbeam and pear have a texture with mild pattern and ash, Apple and walnut, on the contrary, have a very interesting, bright picture, especially in the transverse and diagonal cut.

Great importance is the grade of wood that you will carve candle. The fact that turning wood is only possible when using hard wheat. Conifers categorically do not fit, they can be immediately forgotten. Respond well to turning: beech, ash, pear, Apple, cherry, oak, hornbeam, chestnut and others about the same hardness. In addition to hardness, the value is the texture of the material. Turning wood give good results, if the wood is beautiful. Plain varieties in the finished product will not look good. For example, beech, hornbeam and pear have a texture with mild pattern and ash, Apple and walnut, on the contrary, have a very interesting, bright picture, especially in the transverse and diagonal cut.

Recommended

The most effective methods of seed germination

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I...

Retro-reflective paint. The scope of

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic...

How to make icon with your own hands - options izgotovleniya (simple and complex)

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make...

But especially the beautiful texture of an adult tree, white acacia, drawing in a divorce reminiscent of the famous stone malachite besides wood acacia is also green. Good textural appeal possess some afrikanskie varieties. For example, paddy the present red-brick color, grade, Kevazingo has a dark chocolate shade, and wood Makor color of coffee with milk. The most noble coloration in the wood of rosewood on the words of this texture is difficult to pass. Turning wood possible on any hard material, and the choice of wood is entirely up to you.

But especially the beautiful texture of an adult tree, white acacia, drawing in a divorce reminiscent of the famous stone malachite besides wood acacia is also green. Good textural appeal possess some afrikanskie varieties. For example, paddy the present red-brick color, grade, Kevazingo has a dark chocolate shade, and wood Makor color of coffee with milk. The most noble coloration in the wood of rosewood on the words of this texture is difficult to pass. Turning wood possible on any hard material, and the choice of wood is entirely up to you.

Set our billet in the lathe, one end clamped in jaws and the other end propped up by the tailstock center. The center can be rotating or stationary, in any case, his nose will reliably support the future candlestick. But still need from time to time to draw back the focus, not forgetting that turning wood at home require special attention and care to accident from the machine is not left blank. Next, choose the rotation speed. For grinding of products with a diameter of 38 mm would be the optimal rotation speed of the spindle 350 – 450 rpm. For grinding and polishing speed will need to increase about two times.

Set our billet in the lathe, one end clamped in jaws and the other end propped up by the tailstock center. The center can be rotating or stationary, in any case, his nose will reliably support the future candlestick. But still need from time to time to draw back the focus, not forgetting that turning wood at home require special attention and care to accident from the machine is not left blank. Next, choose the rotation speed. For grinding of products with a diameter of 38 mm would be the optimal rotation speed of the spindle 350 – 450 rpm. For grinding and polishing speed will need to increase about two times.

You must First pierce the billet along its entire length to even out the surface and get the right smooth cylinder. Flawless, smooth surface needed for marking. All dimensions from the drawing is transferred to the surface of the workpiece. For this measure those lengths and put a pencil mark. Then run the machine and rotating parts apply the pencil at the marked points, we obtain a smooth circular border. After doing this you can start to carve the product. But it is necessary to constantly monitor the process, the better to fathom, not to be mistaken in calculations. Turning wood - it is fun and creative, with the right approach can deliver a lot of fun.

You must First pierce the billet along its entire length to even out the surface and get the right smooth cylinder. Flawless, smooth surface needed for marking. All dimensions from the drawing is transferred to the surface of the workpiece. For this measure those lengths and put a pencil mark. Then run the machine and rotating parts apply the pencil at the marked points, we obtain a smooth circular border. After doing this you can start to carve the product. But it is necessary to constantly monitor the process, the better to fathom, not to be mistaken in calculations. Turning wood - it is fun and creative, with the right approach can deliver a lot of fun.

Article in other languages:

DE: https://tostpost.com/de/gem-tlichkeit/8296-dreh-holzarbeit-handwerk-oder-kunst.html

PL: https://tostpost.com/pl/komfort-domu/8297-tokarki-pracy-w-drewnie-rzemios-o-czy-sztuka.html

TR: https://tostpost.com/tr/domashniy-uyut/8303-torna-do-rama-zanaat-ya-da-sanat.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

How to grow strawberries in the pipe?

All who have a garden or cottage you know how it is difficult to grow large sweet strawberries. We wait all winter, when the long-awaited summer, to feast on berries. But often our expectations are in vain: the summer's cold, no s...

The pressure in the expansion tank of the heating of the closed type: the user, the principle of

As we know from school physics course, liquid when heated, expands in volume. As in heating systems, the elasticity of the pipes is not high enough to accommodate the increased volume, the pressure increases. This often leads to r...

Chipboard - an essential element of the construction

chipboard is widely spread in the modern world, and in particular in construction. It remains an essential ingredient for the production of doors and window sills, is the basis for the walls, ceiling and floor coverings. chipboard...

Aluminum radiator heating: characteristics and features

Aluminum radiators are made through casting and related alloys. Thanks to this production process it is possible to provide them with such essential properties as high heat and lightness. At the moment, the aluminum radiators are ...

Blackout fabric "Blackout" (Blackout). Curtains blackout: overview, features, models

a Few years ago in our country behind the rest of the world most popular fabric for making curtains that share a common name “Blackout” (Blackout). However, not all know about this amazing fabric and not have enough in...

Protection to the stairs from the kids with their hands

Modern two - or three-story house is impossible to imagine without a ladder. But when it was originally issued, it becomes the "highlight" of the interior. But if you have a child in the house – the stairs are fraught with s...

Comments (0)

This article has no comment, be the first!