Now - 23:49:36

Axlebox nodes: description, faults, construction and repair

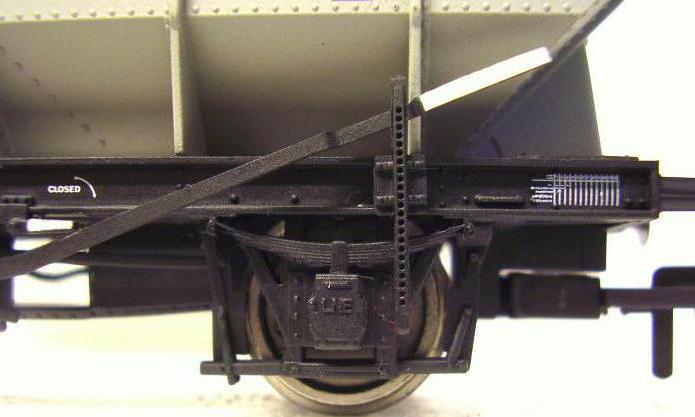

Axlebox nodes are used to transfer the pressure of the car, which he creates by acting on cervical wheelset, and also to limit longitudinal and transverse cross-section of this pair.

Device node

If we talk about the structure of the axle unit, then it is important to note that it is the most important part of car wheel pair. The installation or dismantling of this element is also in conjunction with installation or replacement of wheel sets. In addition, as described above, the node is also designed to establish a strong connection between the pair of wheels and a bogie frame. Engagement is via netbooklive for suspension. Another task for which it is intended axlebox node of the car became a storage of lubricant for roller bearings. In other words, this part is a kind of container. This element also restricts unnecessary movement of the pair of wheels relative to the bogie frame and transmits the load weight of the car on the shaft.

Part of host

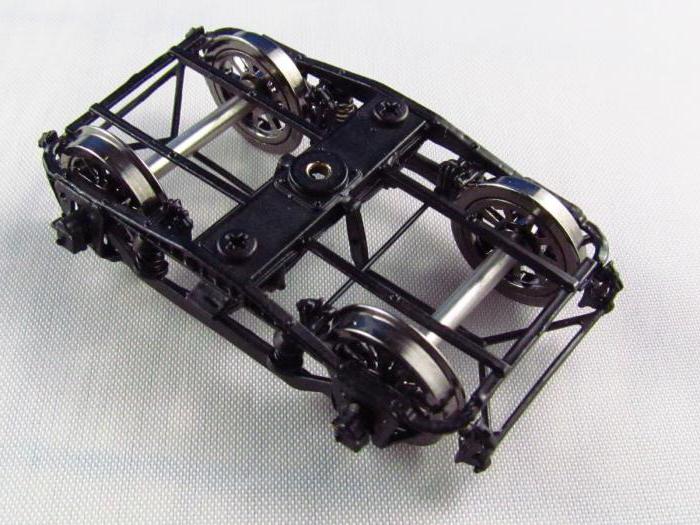

The Axlebox node of the freight car consists of many parts.

The First part is a housing with tides, which are intended to be for suspension.

The Second element of a node is a labyrinth ring. The location of the parts - back housing cover bushing. It pressed in on predpochteniy part of the axis.

The Following element is roller bearings. The node element consists of an inner ring, the separator has a cylindrical roller and has an outer ring.

Next, small detail, which is called the thrust washer and is located between the roller bearings.

Another device that is designed to install the outer bearing is a Circlip.

Cup washer or castle nut is necessary in order to carry out the mechanical fastening.

Axle equipment also has a mounting cover, felt and rubber gaskets between the parts and the inspection cover.

All these elements are connected in a single node, which received the name boxes.

Connection Method

Currently there are two types of attachment node to the truck. They are called jaw and jawless.

If we talk about the second embodiment, in this case, the body of the node, for example with a passenger car will have two brackets, which are designed to implement such procedures for installing node as nadmuchowe spring suspension. Mounting parts of a node have holes through which they are attached to the frame of the truck using such details as spinoni. In such cases, the installation of the labyrinth part of the bushing is cast, together with her enclosure and forms a one-piece design.

It is Very important to monitor the temperature of the bushing during the movement, but because the top of the case has a blind hole which is specifically designed for mounting SCNB. SCNB abbreviation stands for the indicator control of heating books. I should add that when mounted this way the labyrinth ring adpressed and is only installed on the preliminary heating of this part to a temperature of 125-150 degrees Celsius.

What kind of malfunction axle unit may occur?

As this item has many parts as well as parts that move, their wear, abrasion and damage are quite logical. And for the reason that passenger or freight cars carrying a large number of people or valuable material, failure of the node would entail almost a catastrophe.

Symptoms may include the following:

- The destruction of the bearing. This files most often is due to the fact that the roller gets jammed, and it ceases to do a rotational movement.

- You May experience such problems as the violation of the butt holder. This files most often is due to the fact that the nut coming off the axle or break the head bolts.

- Possible such a failure, as the rotation of the inner ring of the bearing or fracture the neck axis.

- The Fault is considered to be the point at which the temperature of heating of axle unit exceeds 70 degrees Celsius.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Symptoms of a node

There are a number of signs, which can determine that the performance of this element of the wagon is broken and require inspection and repair. Such signs include a grinding or tapping, which periodically becomes audible during the movement of the whole.

As the bearings inside metal boxes, the sound of these items peresypaya when driving, is also a sign of the failure of a node. Incidents such as the escape of grease from the labyrinth ring, scale or color tint on the bushing, the presence of smoke from a node or its smell after stopping the car, are also signs that Bush is malfunctioning and needs repair. Symptoms axle unit applies also a too high temperature in the upper part of the element. Notice this sign is easier than others, as is the control over this parameter, it triggered an automatic alarm.

Traffic Safety

Traffic Safetythe entire train strongly depends on the correct operation of this node. Due to the fact that the composition develops a fairly high speed, the temperature of the heating bushes can grow very fast - up to 20 degrees Celsius per minute. Because of the strong overheating increases the chance for such damage, as the crank ring or jamming the entire part. The occurrence of one of these two faults axle unit will entail the gathering of the wagon with rail.

Bush locomotive

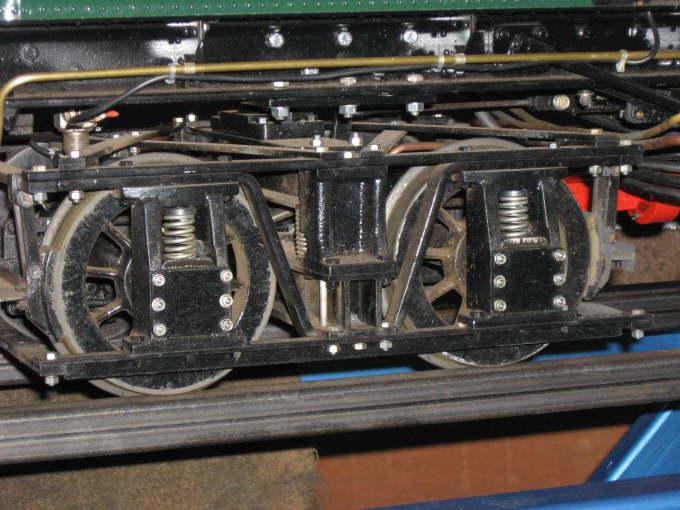

To Carry out repair work is necessary or for a term set by the technical documentation, or when a breakdown occurs. The differences between the structures of this item freight car or locomotive is almost there, but because of the example repair axle unit can be seen on this model of the electric locomotive VL80 as.

Parse the node starts with the fact that the nut turns, and then knocked out the bolt. It is important to check his thread. It should be noted that wash all parts of the boxes is also an important part of the repair, as pollution will cause the bearings to stop rotating. But here we must consider the fact that after washing before disassembly item must not occur more than 6 hours. It is argued by the fact that a longer presence of moisture on parts will lead to a too rapid corrosion.

Things to check when repairing

A Very thorough inspection must be subjected to the bearings of the axle unit and eyeliner. The liner, which is recognized suitable for further use, send on a magnetic flaw detection. Those that are considered more unserviceable, dismantled and transferred to the place of inspection, Assembly, and formation of connections.

Roller bearings are subjected to a very thorough wash. First they are washed with soap emulsion, then once washed in petrol, then wipe them dry with napkins. After they also undergo procedures such as inspection, measurement and fault detection.

During the inspection of these elements is very important to pay attention to the presence of defects such as traces of overheating, cracks that often occur on rings, cages or rollers. It should be noted that almost 37% of all faults in axle-box assemblies arises from the fact that fatigue failure occurs or the wear of the centering surfaces of the separator.

Article in other languages:

AR: https://tostpost.com/ar/business/21640-axlebox.html

HI: https://tostpost.com/hi/business/23213-axlebox.html

JA: https://tostpost.com/ja/business/21217-axlebox.html

PL: https://tostpost.com/pl/biznes/41231-buksovye-w-z-y-opis-usterki-budowa-i-remont.html

TR: https://tostpost.com/tr/business/36036-buksovye-siteler-a-klama-ar-za-in-aat-ve-onar-m.html

UK: https://tostpost.com/uk/b-znes/39986-buksovye-vuzli-opis-nespravnost-konstrukc-ya-remont.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Sterlitamak petrochemical plant: history, production, address

JSC «Sterlitamak petrochemical plant" (snkhz) is a unique production that produce competitive multidisciplinary production of low-tonnage chemicals, additives and synthetic rubbers. High quality product and level of ser...

Tips on how to quickly sell on "Craigslist" thing

In the modern world every minute on the market new products. XXI Vek was not without reason called “era of consumption” - people constantly buy and sell. If you live in a city, then most likely you are not alien to the...

Polishing - what is it? The essence of the process, description, types

polishing is a process by which surface metal is removed all impurities and imperfections and it returns to its original luster.Methods of executioncurrently, you can allocate more of the following types of polishing of metal surf...

The largest plants of Volgograd

Volgograd – the largest industrial centre of the Volga region, located at the intersection of important thoroughfares. Plants of Volgograd made an important contribution to the development of the region, it is the content of...

Kiln-drying of wood: technology, pros and cons

Wood in the form of finished lumber, plywood products and particle Board panels remains the basic consumable raw materials for many fields of industry and construction. Its environmental friendliness and flexibility in processing ...

What is eddy current testing? Features, scope

To identify deficiencies in the internal structure of constructions and details of used methods of nondestructive testing. They allow no intrusion into the base material to fix the defects of different kinds, determining their com...

Comments (0)

This article has no comment, be the first!