Cutting conditions in milling operations: calculation, definition, and standards

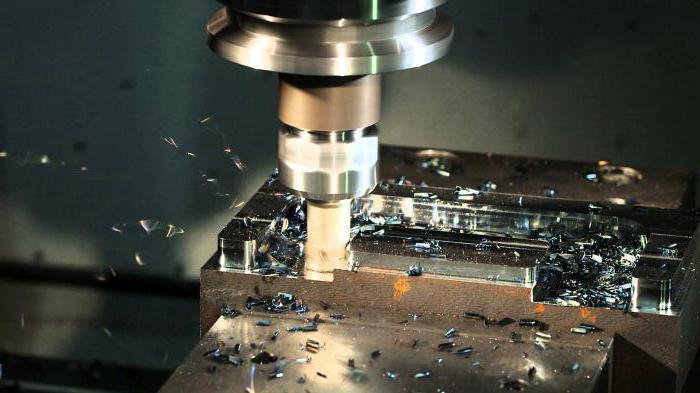

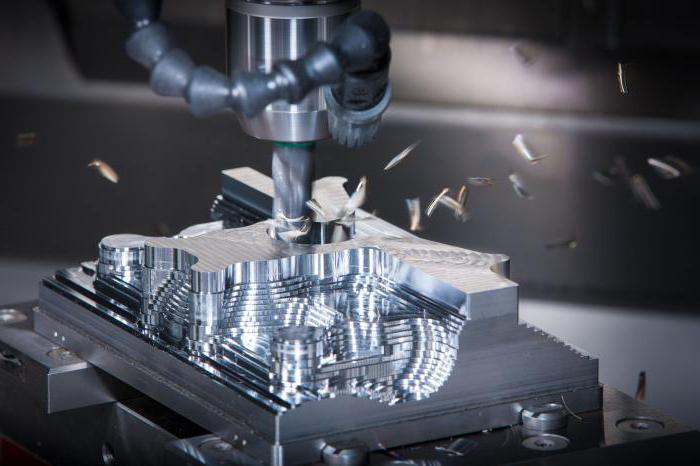

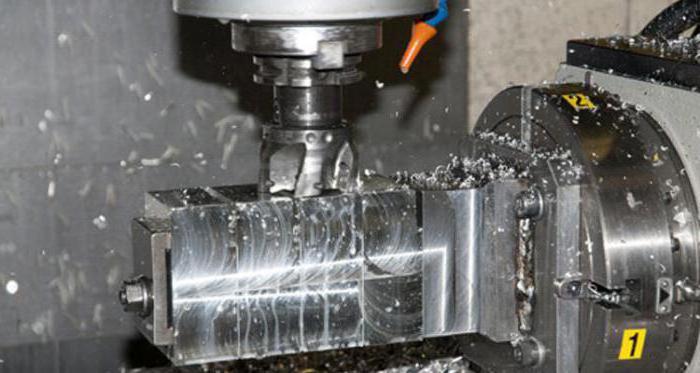

Milling – this is not the most simple operation for processing of metals and other materials, which is not always in the details known to the average person. The fact that this process requires a special device called a milling cutter – it can be found in many enterprises, factories, plants. How is this process? In this case, it involved the cutting tool and the workpiece. The cutting tool is a milling cutter itself – it makes a rotational motion, in contrast to the workpiece, which machine performs reciprocating motion in the direction of the mill. The result is a type of processing that would be difficult to replicate using any other tool. However, this article will not be considered surface information-this material is designed for those who already more or less familiar with the milling process. The main centerpiece here is the mode of cutting, so there will be calculation and determining how it should function and what the cutter head for her to use for specific types of metal of different hardness. To make it easier to understand the data that will be provided next, you should know what will be used here is the concept.

Everything you need to know

So, each item will be specified what kind of material is considered, as well as its hardness method Brines – the most famous and popular of all methods for determining the hardness of bodies. they are Measured in HB, that is, the hardness Brines. Next will be to decide the cutting speed, which is specified in meters per minute (m/min). Here you should pay special attention to the fact that it is not the speed of the cutter, namely, a completely different setting. This option will be considered with a few examples – if the material that is processed by the milling cutter, has no additional coatings, as well as if the mill has different types of surface TI-NAMITE. And, of course, will be described another very important parameter of milling – is the feed per tooth. For people far from this area, this option may seem quite unusual, but if you examine its details, everything will become quite simple. So, this parameter is measured in millimeters on the tooth and determines how many millimeters moves the workpiece until the cutter is rotated one tooth. This flow can be calculated, and others – such as, working capital and minute, but the feed per tooth is key. And it will also depend on the diameter of the tool used. Well, all the basic data you've got – now is the time to learn what cutting conditions in milling operations to use in any particular case.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Common application

So the first material, which is considered in this article – it became General use. What's the cutting mode to use for this material? First you need to determine the hardness of the material. If the hardness of the steel is less than 150 units Pinnela, you must set the speed from 150 to 210 meters per minute depending on the coating. 150, respectively, in the absence of the coating, and 210-in the presence of the most effective coating TI-NAMITE-A. with regard to the feed per tooth, here all depends, as mentioned earlier, the diameter of the tool. If its diameter is less than three millimeters, the feed per tooth will range from 0.012 to 0,018 mm, with the growth of diameter 5 mm, flow increases to 0,024 mm, if the diameter is increased to 9 mm, then the flow increases to 0.050 mm, a diameter of 14 mm, the flow may increase to 0.080 mm, but with a maximum diameter of 25 mm feed per tooth will be 0.18 mm. These data and allow you to choose the right cutting mode. But do not forget that there are more types of solid steel for General use. With a hardness of at least 190 units Brines speed should be 120 to 165 meters per minute, and with a hardness of at least 240 units Brines – from 90 to 125 meters per minute. Of course, changing the feed per tooth. It is diminished in the first case can be from 0.01 to 0.1 mm / tooth, while in the second case – from 0.008 to 0.08 mm per tooth. Of course, this is not the only material used in the milling, so you should pay attention to the other metals.

Case hardening steel

Cutting data when machining case hardening steel will depend on the hardness of the material. If it is less than 235 units Brines, and the cutting speed is appropriate – from 100 to 140 meters per minute. With a hardness of less 285НВ dropping – from 80 to 110 meters per minute. But it is not necessary to forget also about the feed per tooth. In principle, it can not talk a lot, because it is not different from what you have seen in the previous paragraph. In the first case, it will have the same intervals, and in processing steel for General use hardness less 190НВ, and the second – the same as when machining steels for General use hardness less 240НВ. But this is not to say that the feed per tooth will be identical, because maximum diameter of the tool in the first case, the flow rate is not 0.1, as in the previous example, and 0.15. Therefore, the calculation of modes of cutting is a challenging task which is best done by all standards and in accordance with strict regulations.

Nitride

Calculation of the cutting conditions in the processing of nitride steel is no different from previous occasions – only in this case the material is a bit more solid than the other one therefore, you should not be surprised that the cutting speed here is from 90 to 125 meters per minute at less than solid steel and from 70 to 95 meters per minute with a more rigid material. As for feed per tooth, then in the first case it is quite standard run of step – from 0.008 to 0.08 millimeters, but if the metal will have a large number of hardness Brines, it will mean that its supply will decrease, and noticeable. With a minimum diameter of the tool, it will be 0.006 mm, and at maximum – 0.06 mm. At the moment this is the lowest feed per tooth covered in this article. The calculation of the cutting data on this information is quite usual for the standard formula, which will be described at the end of the article.

Medium carbon steel

Medium carbon steel is very common as most importantly – there are several different levels of hardness. And, of course, each of them is its cutting speed. For example, the first two types of steel have the same denominator, if the milling cutter no coating – 80 meters per minute. But at maximum coverage the first type, the speed increases to 110 meters per second, and the second – only to 85 meters per second. But there are two more types, the first with hardness less 340НВ, and the second – at least 385НВ. Accordingly, the first parameter will be cutting 50 to 70 m/min, and the second – from 35 to 50 m/min compared to the types that you have seen before, it's pretty low speed. Accordingly, these types of steel and the feed per tooth too high – we should also highlight the last of the hardness of the steel, which with a minimum diameter of the tool has incredibly small supply, just 0.005 of a millimeter. It is worth noting that this is milling, not the cutting conditions in turning. As mentioned above, for calculation used the formula with which you are familiar above. Cutting data when turning is calculated slightly different formula, so you should not try to apply one calculation to all kinds of works.

Tool steel

Tool steel in hardness are divided into more species than medium, so the cutting parameters during milling of tool steel can be numerous. Briefly tell us about this steel, there are five types of hardness: less 230НВ less 285НВ less 340НВ less 395НВ and more 395НВ. Each of them has its own cutting speed: from 90 to 125 m/min, from 70 to 95 m/min, 60 to 85 m/min from 45 to 65 m/min and from 30 to 40 m/min, respectively. In fact, the name of this data you will be halfway to filling all the missing gaps in the calculation formula, which are determined by the cutting conditions during milling. To the formula all variables are replaced by numbers, you also need to know the diameter of the tool (and derived from it the data on the feed per tooth).

How to choose mode?

The Choice of modes of cutting is pretty simple – each cutter has a switch that will allow you to control the speed of rotation of the cutting tool. With this little switch you can set the approximate...

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Production of mineral fertilizers in Russia: main areas

Despite progress in science and technology, there are areas where the old and tested methods can not do. One of them-agriculture. Hardly possible to grow good grains, vegetables and fruits without the use of fertilizers. Productio...

Chain stores "Mebel cheaper here": the feedback of employees and customers

One of the leading suppliers of soft furniture in Russia is OOO «Furniture cheaper here”. Feedback from employees and customers, the scope of activities of the company, the offered range of products will be examined in...

The types of activities subject to licensing and exceptions to them

the Establishment of the licensing rules of doing business is one of the instruments of participation of the state and its institutions in the regulation of economic relations in society. The most common form of this regulation is...

What better manure (horse or cow) for a vegetable garden?

Dung — one of the best fertilizers to use which can be both vegetable and horticultural or ornamental crops. Apart from the huge number of nutrients, the composition of this feeding system include different sorts of vitamins...

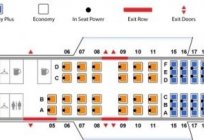

Passenger airliner Boeing 757-200

Officially, the development of Airliners, the Boeing 757 began in August 1978. The Boeing 757-200 was developed by us company Boeing model is the Boeing 727. New aircraft intended for operation on domestic routes and on internatio...

What is threshing? The General concept, features

nowadays, many of the concepts that were relevant centuries ago are still incomprehensible to the inhabitants of cities. Those who are interested in the peculiarities of rural life, will certainly be interesting to know what thres...

Comments (0)

This article has no comment, be the first!