Now - 23:28:31

Floating floor: the design and the device

The Concept of floating flooring was a long time and in the early stages of development was expressed in the refusal of the adhesive method of installation. The transition to mechanical locking connection of the elements of the flooring was motivated by the desire to eliminate or minimize deformation processes. They arose because of natural progress of the foundations of the building, which was reflected in the decorative coating. Accordingly, the denial of direct conjugation with carrier base extended the service life of stacked material. Today, floating floor – not just shaped locks set of coverage elements, and technologically advanced in design, devoid of close mates with a rough basis.

General information about the technology

To Solve the problem of eliminating, at first glance, a required component cords in the design of floor coverings in different ways. And here it should be noted that increasing the strength of the deck with the protection of its structure – is not the only objective pursued by the authors of the technology. For example, when laying laminated panels to the fore the challenge of ensuring sound insulation. Technically, the floating flooring system is implemented by the device damping layers. Again, the choice of materials for such a facility and its construction will be determined by the requirements to the result. To eliminate the risk of deformation of the expensive flooring in the form of a laminate or wood flooring help and lateral wedges. This special hardware, softening impact during dynamic loads on the floor. But most often the floating cover associated with the major device substrate that connects the decorative layer on the surface and base.

Recommended

The most effective methods of seed germination

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I...

Retro-reflective paint. The scope of

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic...

How to make icon with your own hands - options izgotovleniya (simple and complex)

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make...

Materials and consumables

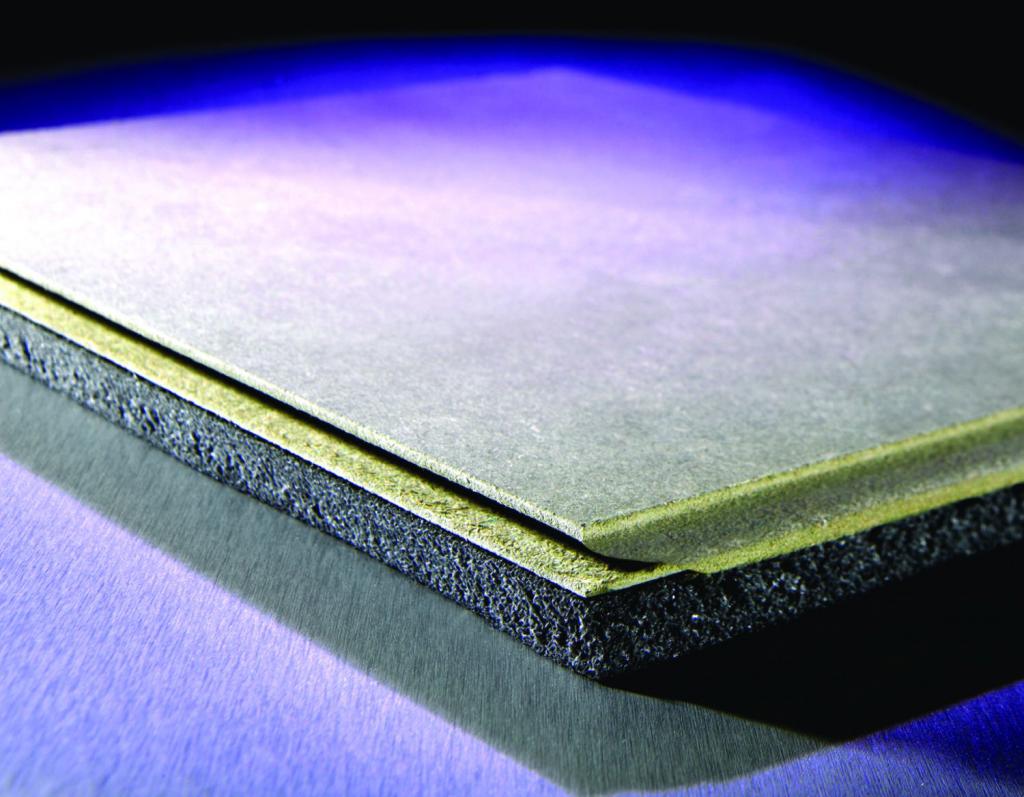

Immediately, it should be emphasized that the flooring is not an element of the damping system. Except that the linoleum with cork as such can be part of this feature, but a key element will still perform special elastic substrate. In particular, it can be felt screed, polystyrene or mineral wool. Used sheets or panels with a thickness of 4-5 cm, If you plan to do a substrate under solid coating (Board, laminate, parquet), it is necessary to provide a reinforcement grid. Due to the strengthening thin damping layer of rods will retain their structure and functionality. There is a group of special substrates to improve the sound insulation. So, for the floating wood floor is to use ecoplate, corrugated cardboard or cork mats. The rate of noise reduction depending on the characteristics of a layer is drawn on average from 16 to 26 dB. The same applies to thermal insulation, but in this case the choice is not so wide and usually comes down to the special modifications of the same mineral wool.

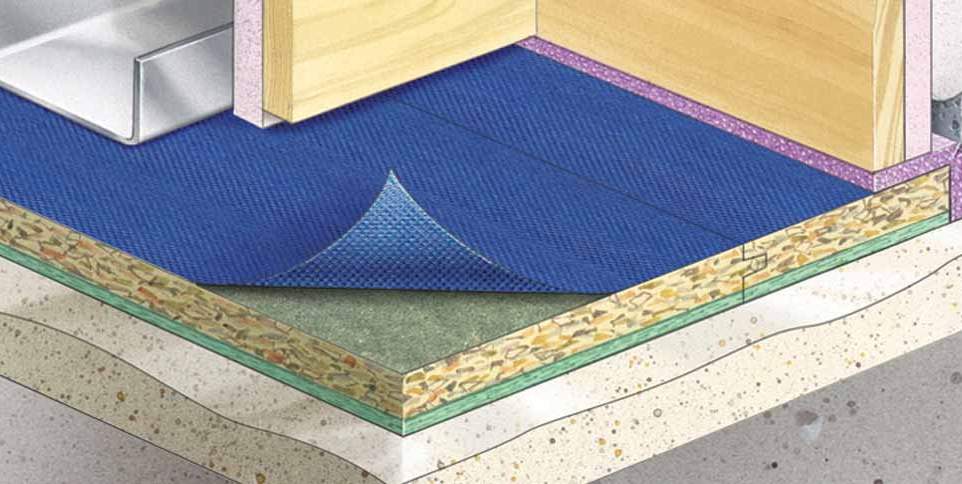

Floor Design

In the simplest systems, the device of the flooring is based on a substrate of the damper and directly to the decorative layer. If rough framework to lay polystyrene, and over-laminate panels, it will be the target system without tight ligaments. Nevertheless, a professional parquet layers implement the floating cover comprehensively and taking into account small nuances of operation. If we consider the system with the lower region, then it will start with a rigid base. Draft at base of stack logs, plywood sheets, screed or self-leveling floor. This layer is needed as the surface on which you sit integrated damper. Then transferred to the backing layer of a floating floor. Design in this part may include the above-mentioned special materials, and expanded clay with rubber. This choice is made based on the requirements to the floor. In addition to providing insulation and mechanical protection, for example, may require device barrier to moisture and vapor. This task is performed by vapor tight foil membrane.

Assembly work

Although a list of the main tasks of the damping substrate includes leveling defects rough surface on the stage of preparation for the work, it is desirable to minimize them. Specially for this and put the hard layer. It should remove the bumps and hide deep pits in them. Even at this level the device floating floors allows for the inclusion of the base isolators. It is useful to roll out thin and vapor - proofing. If we are talking about a private house and there are no major restrictions to reduce the floor height, it is possible to organize a small layer dry sand – it will contribute to warming function. Then proceed directly to the installation of damping material. Already mentioned about the different types of the substrate, but it is equally important to pay attention to the format of its delivery. It can be coils, plates, thin panels and mats. Accordingly, the hard ware is fixed by lock mechanisms (not included), and the elastic material is usually nailed with fasteners or glued. You can now examine the solutions for floating flooringfrom large manufacturers.

Model ISOVER

Under this brand produced a series of panels of mineral wool. The structure of the material is formed by natural components, which include fiberglass, limestone, sand and soda. Is present in the composition and synthetic binding element, but its content is usually minimal. The purpose of these boards were designed as a solution for isolating – noise reduction, insulation, etc. the sound insulation coefficient reaches 37 dB. You'll be a floating floor ISOVER and physical resistance. The rate of compressive strength is about 20 kPa, so this framework can be used in combination with a hard decorative coatings.

Model “fag”

This manufacturer is known for a unique development in the form of water resistant gypsum panels. They are also used as insulators, but in this context it is interesting modification for the device team floor base. It is a floating floor “fag” of gypsum elements with a thickness of 20 mm. the Functional emphasis of the coverage focused on the protection from the spread of moisture in the room, but also the task of leveling the rough reason this stove performs at a high level. Most importantly – initially to create a solid base on which the drywall will be able to operated over the years.

Model ROCKWOOL

If you require specialized solutions for commercial and industrial use, they should go to the family of SeaRox slabs from ROCKWOOL. As the basis of the material used rock wool, the outer portion of which is provided by galvanized wire mesh. Plate thickness can reach up to 70 mm, indicating that the special purpose – the substrate of such a format optimally suited for the arrangement of the workshops, offices, corridors, public institutions, etc. At the possibility of using a floating floor this firm in the harsh conditions indicates the reinforcement of aluminum foil, the presence of glass in some models and other insulating coatings. According to the manufacturer, the leaves SeaRox able to withstand heat loads of about 250 °C. This measure of resistance opens the possibility of using the coatings, even in the decoration of objects of metallurgical industry.

Floor care

The Basic works on maintenance of the design are to update the consumables and the application of protective coatings. This applies particularly to modular systems that allow for the possibility of dismantling. Dismantling the cover, you can replace worn felt pad, deformed plate and old mounting hardware. As for the protective layers, the floating floor from the side of damper is often treated with varnishes and polishes. From physical exertion they did not deliver, but will protect the structure from biological deterioration, which is important for natural materials. Regularly you should check and as a decorative material on both sides. It is desirable that the elastic from the foundations it was separated by an insulator with a durable structure.

Pros and cons of a floating floor

With the advantages of technology was obvious. It allows to minimize the physical load on the decorative surface improves insulation quality, and generally makes the floor more pleasant. But the weaknesses of this design should be considered. They are reflected in the complexity of works, costs and the need for special services. In small apartments the technology of a floating floor at all is undesirable because of the reduction of height in the room. At least the flooring will be raised to the thickness of the substrate of a few centimeters, and if you add a group of thin insulators with the reinforcing layer and the underlying rigid Foundation, then it will be about 10-15 cm

Conclusion

Considering the way the floor is more focused on solving the existing problems of its operation. If you plan to use laminate, it can be expressed unpleasant acoustic effects, and in homes with poor external insulation, respectively, will decide the problem of thermal insulation by means of a floating floor. Design and device of the system can be described also versatility. Even using the means at hand with minimal investment, a skilled handyman will be able to realize the structure, increasing the strength of the floor, protection from moisture and cold. If we exclude specialized plates and mats, the functions of insulators can be assigned to the polyethylene, and the damping effect will ensure cork underlay. By the way, in recent practice and the use of pine needles for lining under the laminate panel. It's not the best solution from the viewpoint of improving the strength of the structure, but the insulation with insulation the material provides at a high level.

Article in other languages:

BE: https://tostpost.com/be/hatn-tul-nasc/19018-plavae-padlogu-kanstrukcyya-prylada.html

DE: https://tostpost.com/de/gem-tlichkeit/19031-schwimmende-estriche-der-entwurf-und-das-ger-t.html

ES: https://tostpost.com/es/la-comodidad-del-hogar/19041-piso-flotante-dise-o-y-construcci-n.html

KK: https://tostpost.com/kk/domashniy-uyut/19014-bylmaly-zhynysy-konstrukciyasy-zh-ne-rylymy.html

PL: https://tostpost.com/pl/komfort-domu/18979-pod-oga-p-ywaj-ca-budowa-i-urz-dzenie.html

TR: https://tostpost.com/tr/domashniy-uyut/19024-y-zer-d-eme-tasar-m-ve-cihaz.html

UK: https://tostpost.com/uk/domashn-y-zatishok/19002-plavayucha-p-dloga-konstrukc-ya-pristr-y.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Bearing of the slab on the wall: limits, SNiP

the Rest of the ceiling plate on the wall - one of the indicators of reliability, safety and sustainability of the service life of the building. From the correct installation of plates depends on many things, so all the rules and ...

Professional juicer for apples - description, features and reviews

purchase a professional juicer for apples is a difficult and responsible job. In this article we will discuss the main characteristics of the most popular models and tell you what you should pay attention to when making such an im...

Drain Smolinka: a description of the variety, photos and reviews

Drain – popular culture all gardeners. The sale has many varieties, resistant to pests and diseases and adverse weather conditions. Seedlings are well adapted to the site conditions, to tolerate a transplant and give excelle...

How to make doors in the bath with their hands: step-by-step description and drawings

the Door to the bath with their hands will be able to make any person who has experience with woodworking tools. However, if you do not observe the technology in the room will be drafty, the heat will go out, and hygienic procedur...

How to hang drywall: step-by-step instructions, features and recommendations

Working with drywall literally created a revolution in construction techniques. Because the finish that previously had to perform manually can now be replaced with drywall. He quickly, but efficiently creates a smooth surface, whi...

Ampelnoe geranium - great for decoration of Windows and balconies

Geranium – widely known plants. They gained popularity due to simplicity, beautiful bright flowers and long flowering period. These plants were known in ancient Greece. In Europe they appeared in the XVII-XVIII century ...

Comments (0)

This article has no comment, be the first!