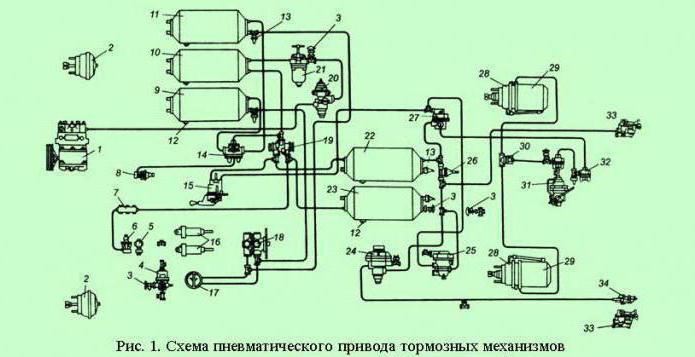

Pneumatic actuator brake system

Pneumatic actuator is the source of energy used for braking and works on compressed air. The subject device provides the opportunity to create a substantial braking force with minimum participation of the driver or operator. This system is widely used in the construction of tractors, buses and trucks. The design consists of a compressor, air tanks, crane, wheel compartments, resubmitting regulator of the vessel for discharge of waste fluids.

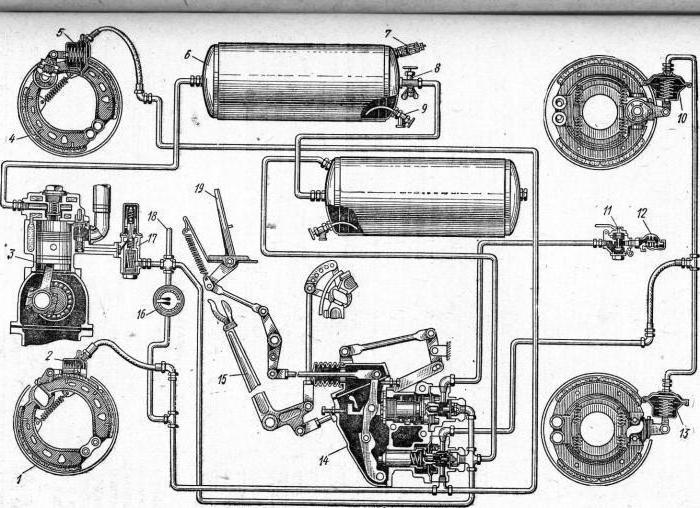

Compressor

This element is a pneumatic actuator supplies the compressed air system. It is processed in the cleaner, and then transported to the tanks. The output air mixture from the cylinders prevents the check valve. The indicator of the pressure determined by pressure gauge. After activation of the brake pedal the air through the opened faucet gets in the brake compartments, resulting in activated compression pads. The reverse process takes place with tensioning springs.

The structure of the compressor includes the cylinder block, head, sump, retaining cover. The crankshaft mechanism rotates in bearings ball type, interacts with pistons with pins and rods. The front part of the crankshaft is equipped with a V-belt, oil seal and key. As the cooler is provided with a fan. In the cylinder head above each work item has a tube with a spring and discharge valve. The lower connecting rod head is equipped with adjustment shims.

Lubrication and cooling

Pneumatic brake actuator has a combined lubricating system. Oil is supplied from the main thoroughfare through the pipe into the inner part of the crankshaft. Connecting rod bearings placed in a solution of anti-friction and lubricated by force. The other elements are oil way of the spray. Working out from the crankcase goes into the tank of the engine through a special branch.

Recommended

The most effective methods of seed germination

Despite the fact that the method of seedling in vegetable production is a very time consuming process, it is used by most gardeners. Planting seeds in open ground is an easy and convenient method, but it is effective only in certain climatic zones. I...

Retro-reflective paint. The scope of

When the vehicle began to fill the road, their popularity began to gain reflective paint. Thanks to this paint, as drivers and pedestrians becomes much easier to avoid accidents in the dark. Purpose paint Reflective paint – paint material, whic...

How to make icon with your own hands - options izgotovleniya (simple and complex)

In Soviet times, many collecting badges, emblems, pennants. To get them was not easy. And today, thanks to technology, you can make them yourself. Knowing how to make icon with your own hands, and you can make original gifts to your friends, and make...

Cooling System compressor pneumatic drive – liquid type. It is associated with the same node of the power unit. When one of the pistons is lowered to the lower position, a vacuum is created and air flows into it through a cleaner and inlet valve. After lifting of the piston is compressing the air mixture, it then flows through the valve to the cylinders and main system. Then the whole process repeats itself.

Measure air pressure limited to a special controller that reduces the power consumption of the motor to drive the compressor, which increases the working life of the node. Design with controller located under the valve contains a pair of plungers and seals with the pushers. The piston arm connects spring cavity under the intake valves aggregates with a pipe cleaner, a piston channel with a pressure controller.

Device pneumatic actuator brake system

The Air cylinders designed for storage of cooled liquefied air supply. Their design includes taps for drain and relief valve. From clogging the device protects cap nut type.

The body of the pressure regulator closed casing has a fitting with stock valves. On the rod affects the spring mechanism, which is equipped with an adjustment cap. In the center console housing is the intake and exhaust valve. The channel is connected through the filter and inlet cylinders, and unloading device. At the bottom of the housing there is a tube.

If the line pressure reaches the figure below 560 kN/m, the mass of air vented to atmosphere. The plungers in this release the intake valve, the compressor starts to pump air into the system.

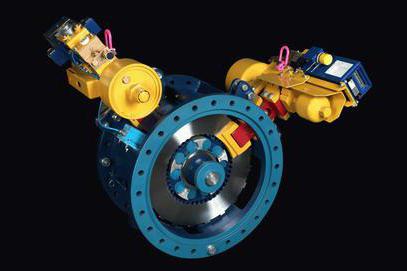

Manage system

Hydraulic pneumatic actuator for control is equipped with a crane. It allows you to regulate the flow of compressed air to the working chambers. Also with the help of which is ensured by stable braking force and a quick release.

The Case is the part fixed on the frame. The diaphragm is made of a rubberized fabric material placed between the cover and the frame. In its center there is a saddle valve, based on the glass of the control spring. The working cavity communicates with the atmosphere through the inlet box and valve. Spring return, consistently affects the diaphragm and the inlet valve. Saddle last element is clamped in the lid fitting. By pressing the valve the air from the cylinders not supplied to the brake chambers.

The work of the pneumatic actuator

Duplici aggregates the lever with the brake pedal, while leaning on the glass. After pressing the pedal rod is placed inside the corrugated protective cover, rotate the lever. A glass of spring fed right, the diaphragm flexes, and then closes the exhaust valve and the intake its analogue offer. Diaphragm-spring mechanism and the valve forms a servo node. It has three positions.

In the first position, the brake pedal is released, both valves be in the leftmost position. The intake valve is active, the brake compartments through it, and the working chambers connected to the atmosphere.

The Second position corresponds topressing on the pedal, the force transformirovalsya on the lever, the Cup and the diaphragm. The saddle covers the valve, divide the connection with the atmosphere. The opening of the valve is further hindered by the air pressure and spring force.

In the third position after further depression of the pedal opens the intake valve, the compressed air mixture is supplied to the brake chambers, the process of braking. The diaphragm under the air bend, and the spring is compressed. After equilibration of forces the diaphragm becomes the second position, both valves are closed, providing a constant braking force.

Features

The Pneumatic actuator of the brakes with greater pedal press gets an extra amount of air. This causes an increase in pressure in the working compartments. When disinhibition processes are proportionally in reverse order. Compressed air mixture exits through the valve. The idle mode is adjustable by a special screw.

For pneumatic actuation of the valves on the trailer-mounted crane of the combined type. It is an element with two sections, the upper of which is responsible for the towed devices, and the lower part – truck. The right divisions of the compartments are identical in the saddle exhaust valve rests on the rod, placed in the mechanism with bushing and spring. On the axis of the rod there is a lever that aggregates with a small counterpart.

Pros

The Use of the device in question due to several advantages, namely:

- Pneumatic actuator gives the opportunity to create a significant clamping force on the pads with a small impact on the control pedal.

- Accessibility, safety and ease of operation in normal air.

- The possibility of the accumulation of a significant amount of potential energy of air in tanks that allows to provide continuous and effective braking in case of failure of the compressor.

- Slight leak air mixture, which is partially kompensiruet the supply of compressed air.

- Simplicity and ease of connecting and conducting components.

- High efficiency.

- Ability to design applications to work a variety of additional automotive equipment.

Disadvantages

Now consider the cons of the device:

- Relatively slow trigger because of the characteristics of compressed air.

- Repair of pneumatic actuator requires a full or partial replacement of the elements.

- The design Complexity and high cost of mesh modification.

- Large weight and dimensions, compared to the hydraulic counterpart.

- Significant power consumption for compressor drive.

- The Possibility of breakage of a node when the condensate freezing in the winter.

The Brake actuator provides high force at the same time contains a lot of elements. For example, on KAMAZ this part includes about 25 of the devices, 6 receivers, about 70 meters of pipeline.

In conclusion

The Design of single-loop pneumatic actuator simple. However, modern standards of safety do not accept its operation due to the low reliability. On cars establish multi-loop counterparts, which are equipped with multiple independent drives. In the modern system, there are two mandatory minimum contour, and up to six circuits of other systems.

In addition, the design of the unit is the mass of instruments designed to ensure the normal operation of the brake elements. They also perform monitoring of actuator on the tractor and the trailer. Consider a system equipped with popular domestic trucks. Particularly relevant this mechanism on the trucks. On machines with extended base often used combined hydro-pneumatic drive of brakes. To make the necessary efforts using compressed air, and the transfer mechanism is carried by the working fluid. Such a system increases the response speed of the structure, but it greatly complicates.

Article in other languages:

BE: https://tostpost.com/be/hatn-tul-nasc/35919-pne-matychny-pryvad-tarmaznoy-s-stemy.html

DE: https://tostpost.com/de/gem-tlichkeit/35576-pneumatischer-antrieb-bremsanlage.html

KK: https://tostpost.com/kk/domashniy-uyut/36217-pnevmatikaly-zheteg-tezheg-sh-zh-yes-n.html

PL: https://tostpost.com/pl/komfort-domu/37398-si-ownik-pneumatyczny-uk-ad-hamulcowy.html

PT: https://tostpost.com/pt/o-aconchego-do-lar/37186-atuador-pneum-tico-sistema-de-travagem.html

TR: https://tostpost.com/tr/domashniy-uyut/32669-pn-matik-akt-at-r-fren-sistemi.html

UK: https://tostpost.com/uk/domashn-y-zatishok/36481-pnevmatichniy-priv-d-gal-m-vno-sistemi.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Remontant raspberry Firebird: a description of the variety

the Growing popularity of remontant raspberry varieties. This is not surprising as developing in a one-year phase culture greatly facilitates maintenance in comparison with traditional concerns for ordinary raspberries, with its t...

How to put patterns on the wall

In an effort to make your home more cozy and unique leaf through a pile of catalogues with samples of Wallpaper, learn a variety of techniques for applying the plaster, trying to experiment with textures. Thus sooner or later begi...

Homemade cutter for the lathe on wood. The types of cutting tools for lathe wood

to create the desired artistic design of wooden cylindrical products with this special hand tool such as a cutter for a lathe on wood. The attention of those who loves to make a wide range of these cutting tools. Anyone can buy hi...

Fire resistant cable: types, brands, features, purpose

fire-resistant cable for many years applied to the power supply. He had previously made on the basis of basalt filaments, fiberglass, mica, and other materials not susceptible to combustion. Production was very time-consuming, and...

Mites: what is dangerous and how to remove it

mites are very common across the globe, so you can find them on absolutely every continent where people have built homes. Since they accompany people, give a person not only the house but also the food.What is this insect?Mites ar...

Roof boilers - description, application

Effective solution to the problem of the centralized heat supply of industrial and civil objects are boiler rooms on the roof. They are placed on the roofs of buildings or on the grounds, which are being prepared especially for th...

Comments (0)

This article has no comment, be the first!