Now - 10:44:31

Galvanized car body with his hands

To protect the back of your car from corrosion, motorists use a variety of methods. Some keep a car in the garage and go in the winter, others wash it weekly, and others are treated with anti-corrosion materials. Unfortunately, to date there is no single correct solution to prevent corrosion, but there is one method that can effectively counter the oxidation process of the metal – galvanization of the body of the car.

This technology is not new and has long been used by some manufacturers. It is much more effective than all existing methods of dealing with rust and is able to resist it for decades. That is a galvanization of the car body we will discuss in this article. We will review the existing methods and application of protective coating in the factory and home.

What is zinc

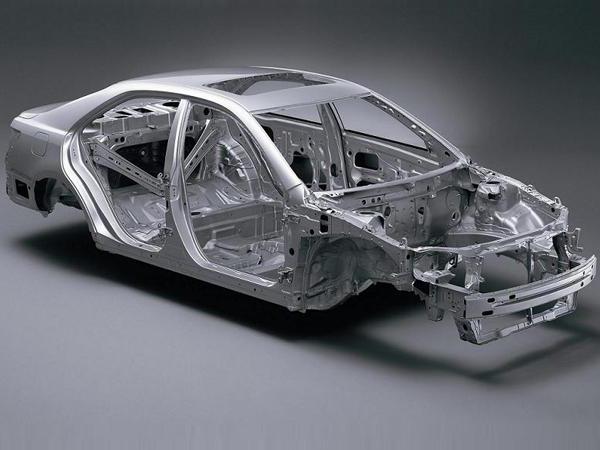

Galvanized body of the car – a process of coating a thin layer of zinc. This metal almost does not corrode and protects the structural elements not only from moisture but also from other chemically active substances. Automakers use galvanized at build time machines. It can be full or partial. In the first case, the processing yield all the elements of the body, both with external and internal parties. The second option involves the coating of zinc only those parts which are most at risk from interaction with aggressive environment: the underbody, sills, wings, etc.

Methods of galvanizing

There are only three ways of applying the zinc layer to the metal of the body:

- Electroplated;

- Heat;

- Cold.

Let's Consider each of these in more detail.

Electroplated

Zinc plating car body involves the placement of it (or its element) in a container of a specific electrolyte. The housing capacity is connected to the positive electrode of the power source, and the processed element – to negative. Deeply immersed in the electrochemical processes, describe the technology in simple language you can. Zinc particulates in the electrolyte, under the influence of electricity is accelerating and begin to move from the anode to the cathode, i.e. to the body, and cover it thin but continuous layer. Electroplating technology galvanizing is considered to be the most effective way of counteracting corrosion, the part covered with a protective layer on all sides.

Heat (thermal diffusion) method of galvanizing

The Thermal method is to place the processed item in a bath of hot zinc solution, where under the influence of temperature protection thin layer placed on the metal. Individual car manufacturers practice applying zinc on sheets of steel, which is made body, still in the process of rolling. This method is slightly inferior in efficiency of electroplating, but also serves as an excellent protection against rust. Be the first to produce cars with hot dip galvanised body began to Americans, but after a few years, the technology spread to Europe.

Recommended

How does the rear bushing front arm and how many it serves?

The Rear bushing front arm – one of the constituent elements of the vehicle chassis. He refers to the guide elements of the suspension together with the levers endures tremendous stress with wheels. However, with this this item, there are many ...

Oil consumption in the engine. Six reasons

It is Hardly possible to find a motorist who would not be worried about the increased oil consumption. It is especially annoying when it happens with another new motor. Here are the most common causes that result in the consumption of oil in the engi...

The exhaust System is designed to remove combustion products from the engine and output them to the environment. It also must be ensured a reduction in noise pollution to acceptable limits. Like any other complex devices, this system consists of seve...

Method of cold application

This method is close to that of electroplating, but it does not require any capacity. It all happens with the help of special electrode, the active composition includes zinc. It connects to the positive terminal of the power source, and the processed element to the negative. In the interaction of the electrode with a piece of zinc particulates under the influence of electricity moving from the cathode to the anode, covering it with a protective layer. Cold galvanizing the body of the car is most often used for the treatment of individual elements and is rarely used by manufacturers.

How to find out galvanized your car

Given that not all companies that manufacture machines that use these technologies protect not be superfluous to know, did your car like handling, and can we hope that her metal able to withstand corrosion. But how to determine the galvanization of the body of the car if it is painted?

The easiest way – to study the user's manual. If the body passed such processing, the document you will definitely find the appropriate stamp. The second method – this is a test machine for VIN code. The response received will contain information about did the body of zinc. Well, the last method – a visual inspection machine. If the body has damage to the paint, and underneath them you will see the distinctive gray layer, you can be sure the car is galvanized. You can also see the bottom, fragments of removing dirt and a layer of anticorrosion. It is advisable to look at the floor of the cabin, tentatively pushing carpet.

Well, the last method – a visual inspection machine. If the body has damage to the paint, and underneath them you will see the distinctive gray layer, you can be sure the car is galvanized. You can also see the bottom, fragments of removing dirt and a layer of anticorrosion. It is advisable to look at the floor of the cabin, tentatively pushing carpet.

Galvanized car bodies: table ways, makes and models

The following table presents popular brand and model car with galvanized body.

Electrogalvanizing | Heat zinc |

"BMW" | "Audi" |

"Mercedes-Benz" | "Volvo" |

Honda (accord, CR-V, Legend, "Pilot") | "Ford" ("Escort", "Sierra") |

"Kia" | "Chevrolet" |

Hyundai | "Opel" ("Astra", "Vectra") |

"Cherie" | "Volkswagen" |

"seat" | "Porsche" |

"Lada" ("Grant") | "Skoda" ("Octavia" and "Fabia") |

Is it Possible to produce zinc at home what will it take

Galvanized car body with their hands is quite possible, however, it means not complete a partial coating with a protective layer of certain elements. These may be areas that are most susceptible to corrosion: the wheel arches, sills, platforms under the feet of the driver and passengers door cards, and where damaged paintwork.

Home method of applying a zinc protection – something between a cold and electroplate galvanization. But more on that later. And now about what it will require.

Required tools:

- Rubber gloves

- Chloride or zinc sulfate (soldering acid);

- A piece of zinc;

- Glass vessel;

- Car charger or battery;

- Cut a clean cloth (gauze);

- Sandpaper;

- Degreaser (solvent);

- A solution of baking soda.

If you are not able to purchase a ready solution of zinc salt, it is possible to cook by yourself. To do this, take sulfuric or perchloric acid, and dissolve in it the pieces of zinc in a ratio of 1:0,4, i.e. one liter of acid – 400 gr. metal.

This is Done as follows. In a glass bowl (the glass jar) pour the acid and immerse it dosed zinc, until they cease to interact. Reaction occurs in the form of dissolution of the metal with evolution of hydrogen. So be careful: wear gloves and away from open heat sources. When the reaction ceases, the solution can be considered ready. Filter and drain the sediment. Now you can start to direct the process.

Ucinkovita body at home

Galvanization of the vehicle body can be carried out only in areas previously cleaned of paint, dirt, dust, rust, process liquids. This place treated is cleaned with emery paper, then degreased and dried.

Now you need to collect the device itself. For him, we first need a power source, issuing 12 V and 1 A output. Perfect battery or charger for it. Next you need to make a zinc electrode. This can either be an ordinary piece of zinc (plate, rod), or enclosure (glass) from ordinary alkaline batteries. The latter option is preferable and much more convenient. The electrode need to wrap the cloth in several layers and connected to the positive terminal of the power source. It is not allowed to rag you wrapped the zinc rod or plate, in contact with the terminal.

Negative lead from the power supply connects to the car body. Further, anything you need – to an impromptu dip the electrode into the solution and slowly RUB it over the work surface. During this process, the zinc particles will settle on the steel a thin layer, creating a protective coating. With proper execution of the work the treated area will have a dense texture of light gray color.

Upon completion of the galvanizing place is washed with a solution of edible salt and dried. In the future it may be covered with soil and painted.

Some tips

Treated area should be thoroughly cleaned and sanded with fine sandpaper to make the surface had no visible furrows.

We can Not allow the cable of the positive electrode or the connection was in contact with the electrolyte.

Washing soda solution or other alkaline solution is required. The only way to neutralize acid residues. Otherwise, the possible recurrence of corrosion processes.

Periodically check the condition of the cloth on the electrode. In the course of work it will slowly burn therefore, timely podmahivala it.

All work produce in the street or in a well ventilated area, safety precautions. Avoid getting acid on the exposed skin and contact of allocated hydrogen off-the foci of heat.

Article in other languages:

AR: https://tostpost.com/ar/cars/20413-galvanized-car-body-with-his-hands.html

BE: https://tostpost.com/be/a-tamab-l/38073-acynko-ka-kuzava-a-tamab-lya-sva-m-rukam.html

DE: https://tostpost.com/de/autos/37690-die-verzinkung-der-karosserie-mit-ihren-h-nden.html

ES: https://tostpost.com/es/coches/37461-el-galvanizado-de-la-carrocer-a-con-sus-manos.html

HI: https://tostpost.com/hi/cars/22096-galvanized-car-body-with-his-hands.html

JA: https://tostpost.com/ja/cars/20069-galvanized-car-body-with-his-hands.html

KK: https://tostpost.com/kk/avtomobil-der/38460-ocinkovka-kuzovyny-z-olymen.html

PL: https://tostpost.com/pl/samochody/40010-ocynk-nadwozia-w-asnymi-r-kami.html

PT: https://tostpost.com/pt/carros/39662-galvanizadas-a-carro-aria-do-carro-com-as-m-os.html

TR: https://tostpost.com/tr/arabalar/34935-galvaniz-g-vde-arac-n-kendi-elleriyle.html

UK: https://tostpost.com/uk/avtomob-l/38876-ocinkovka-kuzova-avtomob-lya-svo-mi-rukami.html

ZH: https://tostpost.com/zh/cars/30556-galvanized-car-body-with-his-hands.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

"IZH 350 Planeta Sport" – frisky Soviet bike

it is believed that of the entire line of Soviet motorcycles "IZH" truly sporty just one. It is easy to guess that it was "IZH 350 Planeta Sport".History motorcycleIn 1973 the factory "Izhmash" was made a real breakthrough: the li...

Technical characteristics of the car McLaren 650S

Prime Minister of the British supercar McLaren 650S was held in Geneva in 2014. Its original price was about 268 thousand dollars. A Spider version was offered for 280 225 $.in Brief about the modelthe McLaren 650S boasts a carbon...

"SUPROTEC" the owner of the car

the Engines of modern vehicles have to meet increasingly stringent requirements, including not only dimensions and weight, but their effective power. However, many are well aware that these figures have an inverse relationship, an...

How to choose a car alarm for the car?

the Question of how to choose the right alarm system for cars, confronts everyone who just bought a car. And this applies not only to new models, recently descended from the conveyor, but also b/transport – everyone wants to...

Tires Hankook Winter i Pike RS W419: reviews

All motorists in our country know about the importance of winter tires. The climate in Russia is very severe and unpredictable over the winter periods of thaw can many times to change the frosts. Of course, to speak in such terms ...

"Lifan" (crossover): description, technical specifications and reviews

There are several famous Chinese firms producing automobiles. Among them – the company "Lifan". Crossover – is the kind of car that is now gaining popularity, and very active. And heads Lifan apparently decid...

Comments (0)

This article has no comment, be the first!