Now - 20:40:22

What is more reliable is the CVT or automatic? What's the difference? Advantages and disadvantages

Driving with manual transmission requires care, and modern man is always in a hurry. Automatic transmission in this respect is much simpler. Electronics itself will think for the driver and will perform all the necessary actions – you can not be distracted from the road. But the device of the automatic transmission is much more complicated than a manual transmission. And the more complicated the design, the lower its reliability. In automotive history there are plenty of bad hydrotransformer boxes, variable speed systems are still poorly understood. Try to find out that more reliably – the CVT or automatic.

Automatic history

The First automatic transmission appeared in 1903, but it is used not in cars, and in the shipbuilding industry. The inventor is a German design Professor Fettinger. This man first showed and offered a hydrodynamic transmission, which could loosen the screw and the power unit of vehicles. So was born the hydraulic clutch, which is a very important site for any automatic transmission.

Later, in 1940, the Americans began to use the automatic “Gidromatik" cars "Oldsmobile”. I must say that the design of the automatic transmission remained virtually unchanged since that time. Automatic transmission consists of two main components. It's the torque Converter and gearbox. The first performs the function of the clutch, and the goal of his work – smooth shifting without jerks. A reducer is a pair of gears meshing. This gives you the opportunity to obtain a solid, fairly compact mechanism that has several steps.

Recommended

"IZH 350 Planeta Sport" – frisky Soviet bike

It is believed that of the entire line of Soviet motorcycles "IZH" truly sporty just one. It is easy to guess that it was "IZH 350 Planeta Sport".History motorcycleIn 1973 the factory "Izhmash" was made a real breakthrough: the line went down the fir...

How does the rear bushing front arm and how many it serves?

The Rear bushing front arm – one of the constituent elements of the vehicle chassis. He refers to the guide elements of the suspension together with the levers endures tremendous stress with wheels. However, with this this item, there are many ...

Oil consumption in the engine. Six reasons

It is Hardly possible to find a motorist who would not be worried about the increased oil consumption. It is especially annoying when it happens with another new motor. Here are the most common causes that result in the consumption of oil in the engi...

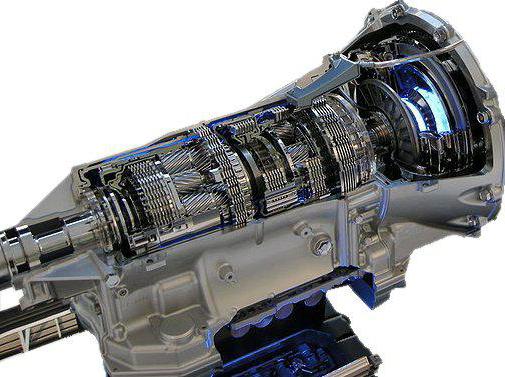

Automatic transmission: automotive part

Let's see how it works transmission "automatic". This system worked inside and out. For many years this design was perfected. In General, the technical part has a sufficient strength and reliability.

In hydrotransformer boxes torque from the power unit is transmitted to driving wheels through a “doughnut”.

There is no hard link. This system works due to the oil that is circulated under pressure. When the rigid gear is not present, and to break down nothing special. But in construction there are also shafts with planetary type gears and friction discs. Packages of friction clutches in the automatic transmission replace the clutch. When they are compressed or opened, connect couplings, corresponding to a particular transmission.

The device has automatic transmission nodes such as the high-pressure pump and hydraulic unit. This is the basis of any automatic transmission.

What usually breaks down in automatic transmission

If you look at the statistics of breakdowns for automatic transmissions, it is possible to see that most of them occur because of deferred maintenance. Not all owners are changing the working oil even after the big runs. The result is clogged the hydraulic unit, radiator automatic transmission, clogged filters. All this leads to the fact that the pump cannot create the required working pressure. Because of this spin the clutch ceases to engage the transmission. Appear twitching and tremors.

Resource automatic transmission

Hard to say what is safer, – the CVT or automatic. At first glance it seems that the CVT as it has a slightly different device, without hydraulic equipment. But high-quality and timely service resource classic automatic transmission can be very large.

There were cases when in the case of oil replacement every 40 thousand kilometers box works more than 400 thousand with no failures. Experts believe that the most reliable "machine" – is an old Japanese four-speed box.

To increase the resource of the automatic transmission, it is necessary to follow certain rules:

- Required to change the oil according to regulations. If the manufacturer recommends changing the oil every 60 thousand, we should not ignore this term. It concerns the so-called maintenance-free "automatic", where the manufacturer filled with liquid is designed for the entire service life. This does not happen - the oil needs to be changed. The best option – complete replacement with flushing on the bench. This will ensure reliable transmission and extended operation.

- Along with ATF fluid change and oil filter. Its timely replacement is able to extend the resource box of 20 percent.

- It is occasionally necessary to remove the radiator. It is blown and washed. Then clean the bottom of the housing from debris – there might be shavings, soot and much more.

By the Way, the chips accumulated on the special magnets. Looks like this phenomenon can be seen in the photo below.

If you follow these rules, the resource of automatic transmissions will increase significantly. Box can go from 300 thousand or more. Because of this, many people choose this transmission.

Box-"automatic": the advantages and disadvantages

Let's Consider the main advantages of automatic transmissions:

- Process control a car with automatic transmission is much easier – no more need to think about how to move the car as slowly release the clutch, what gear is better to include. The computer itself will do everything.

- Also choose the automatic transmission for reliability. Whenquality care auto box is able to walk more than 300 000 km. Also another advantage – high maintainability. The design is well understood, and repair of automatic transmissions may be a large number of specialists.

- Oil – it is also a plus automatic transmission. Automatic transmission requires a special fluid, but the requirements for it are much lower than for variable speed. And the price is less.

- Jerks and gear – it is also a plus. Today already there are multi-stage box. There are even 12-step model. They have a greater maximum speed threshold – the engine is not roaring in fourth gear. Speed switch gently and imperceptibly for the driver.

- Another significant advantage – a small amount of electronics. This is the question that more reliably – the CVT or automatic. Yes, the automatic transmission works together with the ECU, but electronics design is not more than 30%.

Now for the drawbacks:

- Automatic transmission can not boast of such dynamics, as the CVT or "mechanics". Box also has lower efficiency. In automatic transmission engine and transmission have a hard clutch – all assume the torque Converter. So part of the energy expended in the transmission of torque. When it switches there significant aftershocks, which cannot be said about the CVT. Over against him we will see below.

- Also in the automatic transmission should pour more oil – approximately 8-9 liters. At the same time, the CVT requires no more than 6 liters. Another shortcoming – increased fuel consumption. On vehicles with CVT it is the same as the "mechanics".

To summarize, the high reliability overrides all the cons of these units. With proper maintenance and regular replacements, liquid box falls over 300 thousand km, which cannot be said about her opponent.

Variable speed: a brief history

Many believe that the CVT transmission was invented later than the automatic transmission. But it's not. The principle of operation was invented by Leonardo Da Vinci in 1490. But to introduce the unit, he could not, because then there was no ice. Then about the system of forgotten and remembered only in the early 19th century industrial machines. In cars speed regulators were introduced in 58, when Hubert van Doorne Variomatic created. Then it was mounted on the DAF.

Device and principle of operation

This is one of the types of automatic transmission. Box-CVT "automatic" – what is the difference? It is the lack of gears on the CVT transmission. The design represents two pulleys on which the belt is stretched (now, of course, it is a metal). Cones – not one piece construction as before, and sliding halves. If drive pulley is not connected, the belt is rotated by the small diameter of the cone. When the pulley is shifted, formed a small gear ratio that corresponds to the lower automatic transmission.

Moving the pulleys, it is possible to gradually reduce the gear ratios, that is, to switch gears (though their not). These numbers correspond to the steps in the automatic transmission. If you select the box-"automatic" or CVT, the latter is more effective. Here, the maximum efficiency because the transmission of time - hard.

What breaks?

Design loves a quality service. Oil should be changed every 60-80 thousand miles. Changing the fluid is always. If you do not replace it, there will be problems, and recovery boxes will be very expensive.

Among the problems – Zabarauskas hydraulic unit and oil pumps. Because of this, the shafts can't clamp or loosen the belt. As a result, he stalled. It negatively affects his life. The material wears out faster, and at one point the belt simply breaks. And then destroyed everything. Also bully the working surfaces of the shafts that is not the best way affects the condition of the belt. Box-CVT "automatic" – what is the difference? In a large, just a huge number of electronics which can be up to 50% of the structure.

Resource CVT

Here, as well as the transmission, it is necessary for the rules to change the oil. If you don't perform, then the box will fail after 100 thousand. Every 120 thousand need to change the belt. Safer – CVT or automatic? It turns out that "automatic". The variator drive 300 thousand does not work, even if you regularly change the oil.

Pros and cons

Here are pleased more dynamic acceleration, reduced fuel consumption. There are no jerks, the efficiency is 10% higher than automatic transmission. By car it is easy to manage. But that is where the advantages end.

We Continue to view the variator, the pros and cons of the design. Repairing these boxes is very difficult – the design is poorly understood, and experts in the industry have little. The necessary periodic replacement of the belt. It is expensive, and not every station this sort of work. The design includes sophisticated electronics. And finally, another significant negative – oil. It is expensive and hard to find.

What's better?

So we looked at both transmissions. It's time to decide which box is better – "automatic" or CVT. The CVT automatic transmission is better in terms of dynamics and flow. But in case of failure the repair will be very expensive, and not everywhere this checkpoint can be restored or at least maintained. Also requires regular replacement strap, and the design needs qualityoil. Automatic transmission where the winner is more than full.

Conclusion

We considered the CVT, the pros and cons of it. The verdict is this: if you purchase a new car, which will have a guarantee, then buy a CVT can. If it is a car with a mileage of more than 100 thousand kilometers, then it is better to pay attention to "automatic".

Article in other languages:

AR: https://tostpost.com/ar/cars/18487-cvt.html

HI: https://tostpost.com/hi/cars/20149-cvt.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

"Mercedes Viano": description, technical specifications and reviews

To date, the car "Mercedes Viano 639" is one of the best trucks with attractive exterior, luxurious interior and quite affordable cost.Mercedes-Benz offers customers a wide range of specifications of the model "Viano" and power un...

Replacing the timing belt "Renault Megan 2" (Renault Megane II)

Megane of the second generation was produced with a variety of engines with the volume from half to two liters. A common feature of all powertrains is the timing with the belt. The cars were quite popular in Russia and are quite w...

What antifreeze is the best and how to choose it?

Many car owners wonder about which antifreeze is best? In order to answer it, it is necessary to study their technical characteristics. The main purpose of antifreeze is the effective cooling of the car engine and prevent boiling....

MTZ-1025: specifications, reviews. Tractor "Belarus"

the MTZ-1025, specifications of which are presented below, produced at the Minsk tractor plant. The machine is one of the most popular modifications designed for universal use in agriculture and related fields. Like most models of...

Car manufacturer Ford is one of the most popular and in demand among customers in Russia due to the quality and reasonable price for the entire range. Let's look briefly at the lineup of Ford and main features of each car.What car...

MAZ-203 is a comfortable multi-seater three-door bus type

Low-floor city bus MAZ-203 is produced at the Minsk automobile plant since 2006. The machine is radically different from its predecessor, model MAZ-203. The difference lies in the configuration of the lower layer of the cabin. Hav...

Comments (0)

This article has no comment, be the first!